Steel pipes often suffer from rust, scale, and other surface contaminants that compromise their durability and performance. Without proper surface preparation, coatings may fail, leading to costly repairs and potential safety risks.

Steel pipe inner & outer shot blasting machines1 use high-speed abrasive media to clean both the inner and outer surfaces, ensuring optimal coating adhesion and extended pipe lifespan. These machines improve efficiency, reduce manual labor, and enhance product quality.

Shot blasting is a crucial process for industries that rely on high-quality surface finishes. Understanding how these machines work and their benefits can help manufacturers make informed purchasing decisions.

What is a Steel Pipe Inner & Outer Shot Blasting Machine?

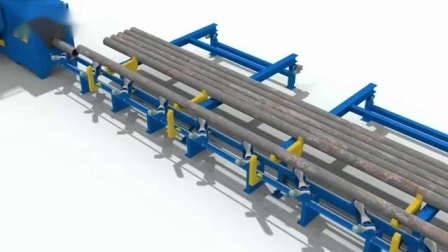

Steel pipe shot blasting machines are specialized equipment designed to clean pipes' internal and external surfaces using high-velocity abrasive media. They remove rust, scale, and other contaminants, preparing the surface for coatings, welding, or further processing.

These machines employ multiple blasting turbines and nozzles, ensuring comprehensive coverage and uniform cleaning across the entire pipe surface. They enhance pipe longevity by improving corrosion resistance and surface adhesion.

How Do These Machines Work?

Steel pipe shot blasting machines follow a structured process:

| Step | Process Description |

|---|---|

| 1. Loading | Pipes are placed onto the conveyor system or rotating mechanism. |

| 2. Internal Blasting | Abrasive media is directed inside the pipe through a nozzle system. |

| 3. External Blasting | Turbines propel abrasives onto the outer surface for uniform cleaning. |

| 4. Dust & Debris Removal | Collected contaminants are filtered out, ensuring a clean environment. |

| 5. Unloading | Cleaned pipes exit the system, ready for the next process. |

This efficient process guarantees a consistent finish, making it indispensable for industries like oil & gas, construction, and shipbuilding.

Why is Shot Blasting Essential for Steel Pipes?

Steel pipes are exposed to harsh environments that accelerate corrosion and wear. Without proper surface preparation, protective coatings may fail, leading to premature degradation.

Shot blasting removes impurities and creates an ideal surface profile for coatings, significantly improving durability and performance. It is a necessary step in ensuring long-lasting steel structures.

Dive Deeper: The Impact of Shot Blasting

Shot blasting provides several essential benefits for steel pipes:

- Corrosion Protection2: Removes rust and scale, reducing oxidation risks.

- Improved Coating Adhesion3: Creates a rough surface profile for better paint and coating attachment.

- Extended Lifespan: Enhances pipe durability, reducing maintenance costs.

- Consistent Surface Quality: Ensures uniform cleaning for industrial applications.

Industries like oil & gas and infrastructure rely on shot-blasted steel pipes to maintain operational integrity. Without proper surface treatment, pipes risk premature failure, leading to significant financial losses.

Key Advantages of Steel Pipe Shot Blasting Machines

Investing in a steel pipe shot blasting machine offers significant advantages that improve production efficiency and product quality.

Increased Productivity

Automated shot blasting systems streamline the cleaning process, reducing labor-intensive manual work. A single machine can process multiple pipes per hour, maximizing output and minimizing downtime.

Enhanced Surface Preparation

Steel pipes require a precise surface profile for coatings to adhere properly. Shot blasting achieves a uniform finish, eliminating inconsistencies that could compromise product performance.

Cost-Effective Solution

Although the initial investment in a shot blasting machine may seem high, long-term cost savings are substantial. Reduced labor, lower maintenance, and improved coating efficiency translate into significant financial benefits.

| Benefit | Impact |

|---|---|

| Labor Savings | Eliminates the need for manual cleaning, reducing workforce costs. |

| Material Efficiency | Optimized abrasive use minimizes waste and operating expenses. |

| Reduced Coating Failures | Proper surface preparation prevents costly rework and repairs. |

By enhancing surface treatment efficiency, these machines provide a high return on investment (ROI).

Industries That Benefit from Steel Pipe Shot Blasting

Several industries rely on steel pipe shot blasting machines to ensure high-performance surface finishes.

Oil & Gas Industry

Pipelines in the oil & gas sector require high corrosion resistance to withstand extreme conditions. Shot blasting ensures that coatings adhere properly, preventing premature pipeline failures.

Construction & Infrastructure

Steel pipes used in bridges, buildings, and highways must meet stringent durability standards. Shot blasting enhances their longevity, reducing maintenance needs.

Shipbuilding & Marine

Marine environments accelerate corrosion. Shot blasting prepares steel pipes for protective coatings, extending their service life in harsh conditions.

My Insights

Steel pipe inner & outer shot blasting machines1 play a crucial role in industrial manufacturing. Without proper surface treatment, steel pipes are vulnerable to rust, coating failures, and structural weaknesses.

Investing in high-quality shot blasting equipment ensures better product performance, reduced operational costs, and long-term durability. Whether in oil & gas, construction, or shipbuilding, these machines provide unmatched efficiency and reliability.

Conclusion

Steel pipe inner & outer shot blasting machines1 are indispensable for industries requiring high-performance surface treatments. They enhance corrosion resistance, improve coating adhesion, and boost productivity. Investing in automated shot blasting technology ensures cost-effective, efficient, and high-quality steel pipe preparation.

Explore the advantages of these machines to understand how they enhance efficiency and product quality in steel pipe manufacturing. ↩ ↩ ↩

Learn how shot blasting effectively removes rust and scale, ensuring long-lasting protection against corrosion for steel pipes. ↩

Discover the significance of surface preparation in achieving better coating adhesion, which is crucial for the durability of steel pipes. ↩