How to Optimize Resin-to-Sand Ratio for Better Casting

Poor casting quality often starts long before metal hits the mold—getting the resin-to-sand ratio wrong can cost you strength, accuracy, and money. Optimizing the resin-to-sand ratio is key to producing strong, accurate, and defect-free castings—while controlling gas evolution, surface finish, and cost. In this guide, I’ll break down what the resin-to-sand ratio is, why it […]

Why Shot Blasting Is the Best Method for Surface Cleaning

Industrial cleaning demands more than just surface removal—it requires precision, efficiency, and safety. Many methods fail under pressure. Shot blasting is the most effective, consistent, and eco-friendly method for industrial surface cleaning—outperforming alternatives in speed, cost, and surface preparation quality. If you’re looking for a method that balances performance with sustainability, it’s time to examine […]

Safety Tips Every Operator Should Know About Shot Blasting

Shot blasting may seem routine, but beneath the surface lies a high-risk environment—one oversight can result in serious injury or production downtime. Shot blasting involves high-velocity abrasive projection, making PPE, pre-checks, and operator training essential for preventing accidents and maintaining production stability. Over the years, through equipment design, on-site commissioning, and after-sales support, I’ve encountered […]

Top 5 Maintenance Tips for Shot Blasting Equipment

Every downtime due to equipment failure cuts into your margins—and it’s usually avoidable. Consistent maintenance of shot blasting equipment enhances performance, extends component life, ensures safety, and reduces total operational cost. As someone who designs and commissions shot blasting systems, I’ve seen machines fail prematurely simply due to skipped inspections or neglected components. Let me […]

How to Select the Right Abrasive Media for Shot Blasting?

I’ve seen firsthand how easily a poorly chosen abrasive can derail an otherwise well-designed blasting process. Selecting the right abrasive media for a shot blasting machine directly affects surface quality, machine longevity, production efficiency, and operational costs. Many facilities underestimate this decision, but from my years in engineering design, I can tell you—it’s one of […]

Why Your Castings Still Have Burrs After Blasting?

You’ve completed the shot blasting process—but burrs still remain. Why does this keep happening? Burrs often persist after blasting due to poor mold design, incorrect blasting parameters, or surface geometry that blasting alone cannot clean. This problem frustrates many foundry engineers and casting buyers. You expect a clean, finished part, but find rough edges that […]

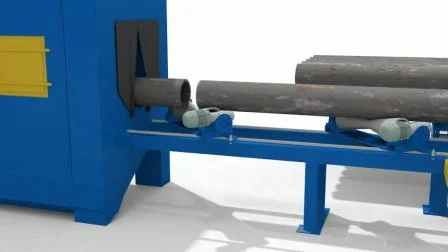

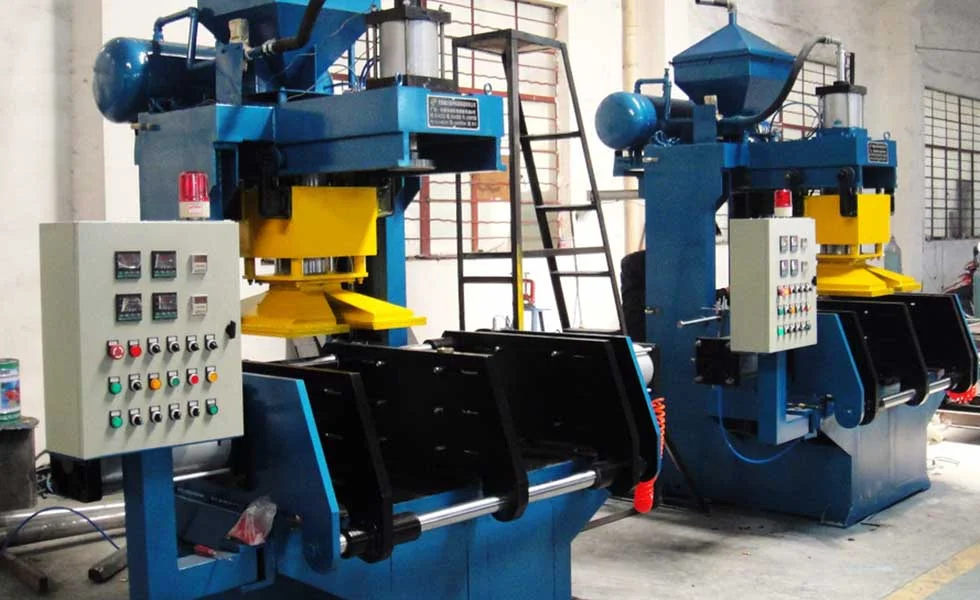

What is a Core Shooter Machine?

Are you still making sand cores manually, struggling with inconsistency and high labor costs? A core shooter machine is a foundry device used to create sand cores by injecting a sand-binder mixture into a core box under high pressure, ensuring precision and uniformity. Modern foundries rely on core shooter machines to produce high-quality cores with […]

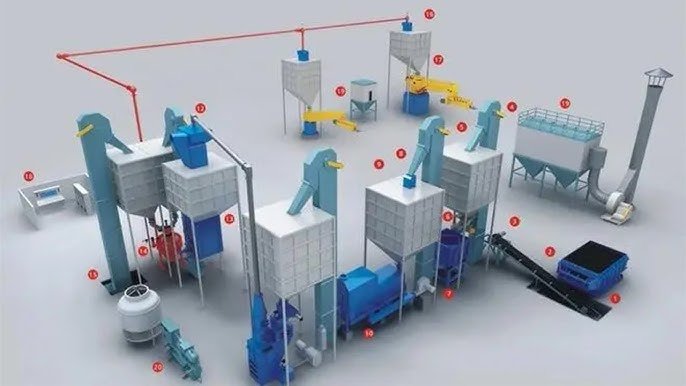

Losing Money to Inconsistent Sand Quality? Fix It with the Right Sand Mixing Machine

Defects, delays, and rising scrap costs—these are often symptoms of one root issue: inconsistent sand quality. It’s silently draining your profits. A reliable sand mixing machine ensures consistent sand properties, reduces casting defects, and protects your bottom line from preventable loss. Sand preparation isn’t just one step in the process—it’s the backbone of mold quality […]

How to Optimize Resin Sand Ratios for Better Molding?

Experiencing mold cracking, dimensional errors, or high gas defects in your castings? You might be overlooking one critical factor: the resin-to-sand ratio. Optimizing resin sand ratios is essential for achieving strong, accurate, and defect-free molds. It impacts surface finish, strength, collapsibility, gas evolution, and overall casting quality. Over the years, I’ve helped many foundries improve […]

Technical Support and Features of the Hanger Shot Blasting Machine

Inconsistent cleaning on irregular parts? Damaged workpieces after tumble blasting? These issues are common in industries handling heavy, complex components. A hanger shot blasting machine suspends workpieces on rotating hooks, exposing all surfaces to high-velocity abrasive media for efficient and thorough cleaning of castings, welded parts, and structural components. As someone who has worked with […]