Paint peeling off? Rust reappearing? Coatings flaking within months? If so, your surface preparation process is likely to blame.

Most finishing failures don’t start with poor coatings—they begin with ineffective surface prep. The wrong blasting method or outdated machine can silently sabotage your entire operation.

Surface preparation is the invisible backbone of any finishing process. If it’s weak, everything that comes after—primer, paint, coating—won’t hold. Here's how to fix that, starting with the machine you use.

The Cost of Poor Surface Preparation?

Paint jobs don’t fail because the paint was bad—it fails because the surface wasn’t ready.

Poor surface prep leads to reworks, warranty claims, product recalls, and safety issues—all of which erode profitability and customer trust.

I’ve seen firsthand how automotive manufacturers suffer when chassis coatings fail during corrosion testing, or how steel fabricators face customer rejections due to improper adhesion. In the shipbuilding industry, premature coating failure can result in multimillion-dollar maintenance and repair contracts—costs that no business wants to shoulder.

Let’s be clear: flawed surface preparation means downtime, wasted material, and lost credibility.

Real-World Impacts of Poor Prep

| Consequence | Impact Area |

|---|---|

| Rework & Scrap | Increased production cost |

| Adhesion Failure | Product performance |

| Customer Complaints | Brand reputation |

| Regulatory Non-Compliance | Legal and safety risks |

| Equipment Wear | Maintenance costs |

5 Reasons Why Your Surface Prep Is Failing?

If you're investing in coating systems but still seeing failure, it's likely due to one or more of these prep problems.

3.1. Inadequate Surface Cleanliness

Residual contaminants like dust, oil, and rust can prevent coating adhesion and cause long-term failures.

Too often, I’ve seen companies clean flat areas but miss corners or inside geometries—those exact areas where corrosion or coating failure later occurs. Manual blasting or low-powered machines can’t consistently reach every surface.

3.2. Incorrect Surface Profile

A surface that's too smooth or too rough leads to adhesion issues and premature flaking.

Ra and Rz values matter. Too smooth? Coating won’t grip. Too rough? Coating might crack or wear unevenly. Without control over surface profiling, consistency disappears—especially over large batches.

3.3. Wrong Abrasive Media

If your blasting media is too aggressive, it damages surfaces. If it’s too soft, it won’t clean effectively.

Using the wrong media for the material type also increases the risk of cross-contamination—a hidden enemy in industries like aerospace and food processing. Also, non-recyclable abrasives drive up your operational costs.

3.4. Low-Efficiency Blasting Equipment

Generic or outdated machines can’t maintain consistent blasting pressure or coverage.

When your blast pressure fluctuates, so does your finish. If the machine isn’t designed for your part’s geometry, shadowed areas or underblasted spots remain. That means one thing: failure waiting to happen.

3.5. Poor Process Control & Lack of Automation

Manual blasting means inconsistency, human error, and missed defects.

I've witnessed teams manually handle blast pressure, part loading, and media flow—resulting in unpredictable results. Without monitoring systems, there's no feedback loop to prevent mistakes from being repeated.

How the Right Shot Blasting Machine Solves These Problems?

With tailored design and modern controls, the right machine transforms your results.

4.1. Advanced Cleaning Power

High-speed centrifugal wheels and fully enclosed chambers ensure uniform, deep cleaning.

Unlike open-air systems, enclosed wheel blast machines clean every surface equally, with powerful airflow and dust extraction. No corner is left untreated.

4.2. Precise Surface Profiling

You can achieve exact Ra/Rz surface specs for specific coatings, from epoxy to powder.

This level of control allows you to match surface roughness to your coating system’s requirements—ensuring durability and adhesion consistency across every part.

4.3. Custom Abrasive Compatibility

Modern systems can handle steel shot, steel grit, and even specialty abrasives with closed-loop recycling.

With a recovery and classifier system, abrasives are continuously filtered and reused, saving money and preventing contamination. Your media stays clean, effective, and efficient.

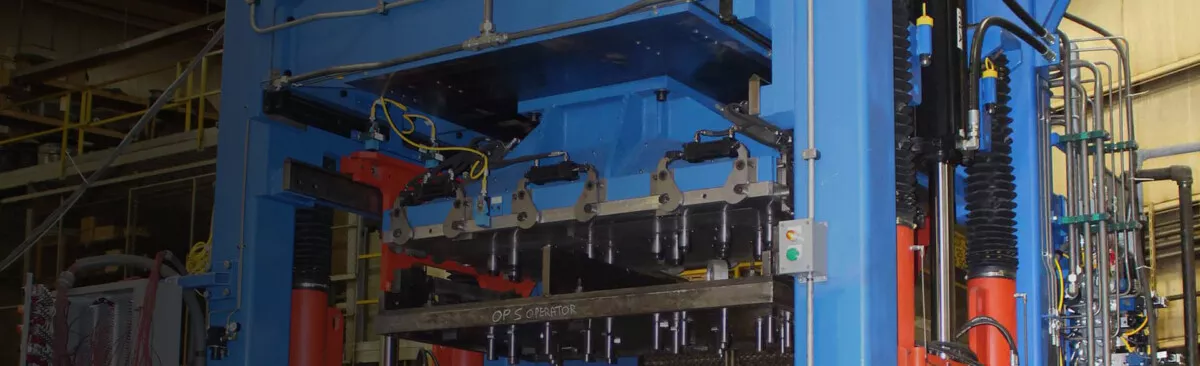

4.4. Built for Your Application

Shot blasting machines tailored to your part—whether pipes, chains, beams, or tanks—are exponentially more effective.

At Hitech China, we’ve built systems with rotating tables, overhead conveyors, and even multi-directional blast wheels for intricate geometries. One-size-fits-all doesn’t work. Precision matters.

4.5. Automation & Monitoring Features

Smart blasting systems track wear, pressure, flow rate, and part location—all in real time.

Automation ensures repeatability. Real-time sensors catch problems early. Maintenance alerts keep the machine healthy. And digital logs help with quality assurance, audits, and traceability.

Smart Machine Capabilities

| Feature | Benefit |

|---|---|

| Blast Media Monitoring | Ensures consistent impact |

| Wear Alerts | Prevents costly breakdowns |

| Part Tracking | QA documentation & traceability |

| Automated Loading | Saves labor and reduces error |

Why Choosing the Right Partner Matters?

It’s not just the machine—it’s who builds it.

Only a specialized partner like Hitech China can deliver a system tailored to your geometry, industry, and surface requirements.

Generic imports or catalog machines don’t solve real problems. With engineered solutions, you get reliable performance, technical support, and measurable ROI.

Working with the wrong supplier often means retrofitting machines, poor after-sales support, and inconsistent results.

Industries That See the Biggest Gains?

Every industry can benefit—but some gain more than others.

High-Impact Applications

| Industry | Benefits Gained |

|---|---|

| Automotive | Rust-free, paint-ready components |

| Steel Fabrication | Beam and weld prep with consistency |

| Pipeline | 360° cleaning of internal/external walls |

| Foundries | Scale and rust removal before coating |

These industries deal with high volumes, structural integrity, and strict coating requirements—exactly where a proper shot blasting system makes all the difference.

Before and After: The ROI of a Proper Shot Blasting System?

Upgrading your blasting system isn’t a cost—it’s an investment in quality, uptime, and throughput.

ROI Highlights

| Metric | Before Upgrade | After Upgrade |

|---|---|---|

| Coating Adhesion | 60–70% success rate | >95% success rate |

| Rework Rates | High (10–20%) | Low (<2%) |

| Abrasive Cost | Unmonitored, high | Recycled, optimized |

| Production Speed | Manual, inconsistent | Automated, fast |

| Downtime | Frequent | Scheduled & minimal |

These are not just numbers—they’re the difference between failing contracts and building long-term partnerships.

Conclusion: Turn Surface Prep Into Your Competitive Edge

Surface prep is more than a process—it’s a strategic advantage. The right machine ensures your coatings perform, your parts last, and your operation thrives.

If your surface prep isn’t delivering, maybe it’s time to stop blaming the paint—and start evaluating your blasting system.

Call-To-Action (CTA)

At Hitech China, we design shot blasting systems that eliminate failure points and transform your surface prep.

Let’s build a machine that matches your exact needs—contact us now to get started.