Facing tighter budgets and stricter environmental rules? Traditional sand disposal just doesn’t cut it anymore.

Modern foundries are turning to resin sand recycling systems to save costs, reduce waste, and improve casting consistency—all while staying compliant with green regulations.

From small facilities to global casting plants, more foundries are making the switch. Here’s why.

Introduction: The Shift in Foundry Practices

Traditional sand disposal methods are no longer sustainable or profitable.

Operational demands and environmental pressures are driving foundries to adopt resin sand recycling systems as a strategic upgrade.

In the past, most foundries simply discarded used resin sand. But growing raw material costs, mounting landfill fees, and environmental scrutiny have changed the game.

Over the last five years, I’ve watched a growing number of foundries worldwide abandon traditional waste-heavy practices in favor of closed-loop sand recycling. The result? Better casting performance, lower operational costs, and fewer regulatory headaches.

What Is a Resin Sand Recycling System?

Still using virgin sand for every mold?

A resin sand recycling system is an industrial solution that restores used resin-coated sand to a reusable state, improving foundry efficiency and sustainability.

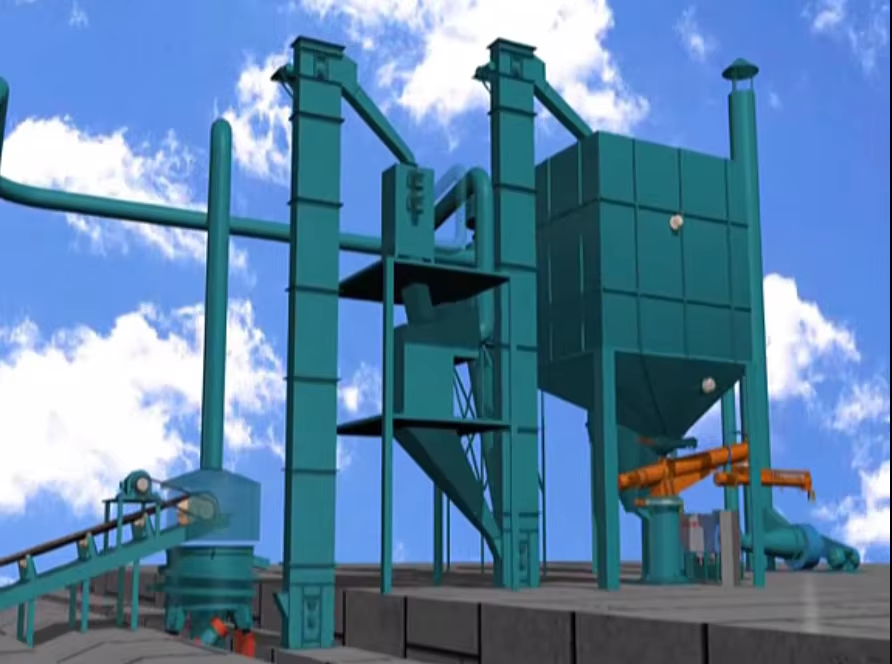

This system reclaims spent molding sand by cleaning, de-bonding, and refining it through mechanical or thermal methods. The cleaned sand can then be reused in new molds, reducing the need for fresh sand.

Compared to green sand systems, resin sand molds are more rigid and accurate—ideal for large, complex castings. However, they’re also more expensive and waste-generating unless a recycling system is in place.

Top Reasons Foundries Are Making the Switch

The numbers—and the benefits—speak for themselves.

Foundries are switching to resin sand recycling for cost savings, improved quality, greater process control, and better regulatory alignment.

a. Cost Reduction on Raw Materials

Reusing sand slashes procurement and logistics expenses.

Every ton of reclaimed sand you reuse is a ton you don’t have to buy, store, or transport. Our clients routinely report 60–90% reductions in new sand purchases.

| Factor | Before Recycling | After Recycling |

|---|---|---|

| Raw Sand Cost (monthly) | $20,000 | $5,000 |

| Transport Fees | $3,000 | $500 |

| Total Savings | — | ~$17,500/month |

b. Minimized Waste and Disposal Costs

Less waste, fewer problems.

Landfill restrictions and hazardous material fees are only rising. By recycling, you cut waste volume drastically—some clients see up to 80% less material sent to disposal.

c. Improved Casting Quality

Cleaner sand = better molds.

Reclaimed sand, when properly treated, delivers consistent grain size and fewer impurities. This results in smoother surface finishes and stronger, more dimensionally accurate castings.

d. Enhanced Process Efficiency

Say goodbye to downtime.

Fresh sand changeovers and manual disposal take time. An integrated recycling line minimizes interruptions and can even feed sand directly into automated molding systems.

e. Environmental and Regulatory Compliance

Recycling systems help you go green—and stay legal.

Governments worldwide are tightening emissions and landfill use. A recycling system helps meet ISO, EPA, and other environmental standards, giving you a strong sustainability edge.

Case Example: A Mid-Sized Foundry’s ROI with Resin Sand Recycling

Don’t take my word for it—here’s what happened in a real-world case.

A mid-sized European foundry saved over $200,000 annually and cut its waste output in half by implementing a resin sand recycling system.

Before Recycling System

- Monthly raw sand cost: €18,000

- Disposal cost: €4,500

- Frequent casting defects due to inconsistent sand

After Recycling System

- Monthly raw sand cost: €4,000

- Disposal cost: €800

- 30% defect reduction

- ROI achieved in 16 months

What started as a cost-cutting measure quickly became a cornerstone of their operational excellence.

Mechanical vs. Thermal Regeneration: What’s Right for You?

Not all recycling is created equal—choose wisely.

Mechanical systems scrub surface resin; thermal systems burn off deeper coatings for near-virgin sand quality. The best choice depends on your casting requirements.

| Feature | Mechanical Regeneration | Thermal Regeneration |

|---|---|---|

| Method | Physical scrubbing | High-temperature burnout |

| Resin Removal Level | Moderate | High (up to 99%) |

| Energy Consumption | Low | High |

| Operating Cost | Lower | Higher |

| Ideal For | General-purpose casting | High-spec precision castings |

Some foundries opt for hybrid systems, combining mechanical and thermal processes for maximum flexibility and performance.

How to Integrate a Resin Sand Recycling System in an Existing Foundry

Worried about disruption? It’s easier than you think.

Resin sand recycling systems can be retrofitted with minimal downtime through smart layout planning and staged integration.

Key Steps for Integration

- Assess Current Layout: Identify space for crushers, separators, and silos.

- Customize Equipment: Tailor throughput capacity to your molding line.

- Stage the Installation: Implement step-by-step to avoid full shutdown.

- Train Operators: Ensure team readiness for the new workflow.

- Test & Calibrate: Run reclaimed sand through test molds to fine-tune.

In most cases, we’re able to complete retrofits in under four weeks with only 2–3 days of actual downtime.

Common Challenges & How Modern Systems Overcome Them

All systems have challenges—smart design makes all the difference.

Today’s resin sand recycling systems are engineered to minimize maintenance, control binder residue, and reduce wear on components.

Problem: Binder Residue Left on Sand

- Old systems lacked enough scrubbing power

- Modern fix: Advanced mechanical/thermal hybrid designs ensure thorough de-bonding

Problem: Sand Grain Degradation

- Old issue: Aggressive crushers destroyed sand shape

- Modern fix: Gentle crushers with adjustable speeds preserve grain integrity

Problem: High Energy Use

- Old thermal systems consumed too much power

- Modern fix: Insulated furnaces, energy recovery systems, and automation cut consumption by 30–40%

If you’re dealing with inconsistent sand or high wear costs, upgrading to a new-generation line can solve these issues long-term.

Conclusion: A Smart Move for the Future of Foundry Operations

Recycling isn’t just about saving sand—it’s about reshaping your entire production strategy.

Switching to resin sand recycling improves efficiency, lowers costs, enhances product quality, and aligns your foundry with the future of green manufacturing.

Contact us at Hitech-China to explore custom recycling system solutions built for your unique needs.

FAQs

How much can a foundry save with resin sand recycling?

Depending on throughput, savings can range from $50,000 to $500,000 annually.

Is thermal regeneration always necessary?

Not always. It's ideal for high-performance castings or when deep resin removal is critical.

How long is the payback period?

Most systems deliver ROI within 12–24 months based on material savings alone.

What types of foundries benefit the most?

Medium to large foundries with high resin sand consumption and tight quality control requirements gain the most from recycling systems.