Dealing with rust, peeling coatings, or inconsistent part performance? The real issue often lies in surface preparation—one of the most overlooked yet critical steps in production.

Shot blasting exists to remove contaminants, reinforce material integrity, and prepare surfaces for coatings. It’s an essential process in modern manufacturing.

In real production environments, I’ve seen countless failures simply because shot blasting was skipped or improperly done. So let’s break it down: why is shot blasting not optional—but absolutely required?

What Is Shot Blasting?

Rust, mill scale, and burrs may seem minor, but they often lead to coating failure, reduced fatigue life, and product rejection.

Shot blasting is a mechanical process that uses high-speed abrasive media to clean, strengthen, or polish metal surfaces. It’s more efficient and eco-friendly than sandblasting.

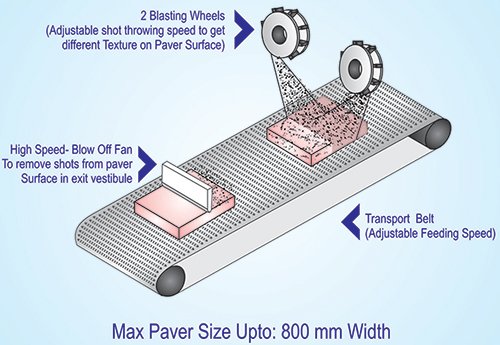

Inside the machine, centrifugal wheels or compressed air propel steel shot onto the part surface. This not only cleans the surface but also creates a textured profile for coatings to adhere better.

Surface Treatment Methods Comparison:

| Method | Media Used | Best For | Limitations |

|---|---|---|---|

| Shot Blasting | Steel shot/grit | Heavy-duty cleaning, strengthening | Higher equipment cost |

| Sandblasting | Quartz sand/non-metallic | Light surface prep | High dust, environmental concerns |

| Grinding | Abrasive wheels | Flat or edge surfaces | Poor for complex geometries |

If you're treating large batches of metal parts, shot blasting remains the most consistent and scalable option.

Why Is Shot Blasting Required?

Paint delaminating? Coating bubbles? Uneven finishes? These problems are often caused by inadequate or missing surface preparation.

Shot blasting is required to remove rust, scale, or old coatings, create surface roughness, and meet industrial surface prep standards. It directly affects coating adhesion and product life.

Core Purposes of Shot Blasting:

- Contaminant Removal: Rust, welding slag, and scale.

- Surface Texturing: Ideal roughness for coatings or adhesives.

- Adhesion Improvement: Stronger, longer-lasting finishes.

- Standards Compliance: Meet ISO, ASTM, or NACE surface conditions.

- Performance Enhancement: Longer life and better corrosion resistance.

Many companies face high returns or premature failures due to poor pre-treatment. With the right shot blasting system, we help eliminate these issues at the root.

Key Benefits of Shot Blasting

This one investment improves quality, durability, and sustainability—what I call the “triple win.” I always tell clients: bad surface prep costs double later.

Shot blasting improves adhesion, increases part lifespan, reduces maintenance, and is aligned with eco-friendly practices.

Five Major Benefits of Shot Blasting:

| Benefit Category | Description |

|---|---|

| Adhesion Enhancement | Micro-roughness allows stronger coating/plating bonds |

| Material Strength | Removes microcracks, increases fatigue resistance |

| Surface Cleanliness | Clears oil, dust, and mill scale |

| Extended Durability | Parts survive harsh environments longer |

| Eco Efficiency | Recyclable abrasives + integrated dust collection systems |

We design our machines to deliver not just performance, but sustainability. With recyclable media and energy-efficient motors, our systems reduce both emissions and waste.

Common Industrial Applications

Not all industries need blasting—but if you work with steel, coatings, or structural parts, you probably do.

Shot blasting is widely used in automotive, shipbuilding, pipeline, infrastructure, and foundry sectors for surface prep, strengthening, and cleaning.

Industry Use Cases:

| Industry | Typical Applications |

|---|---|

| Automotive | Engine blocks, brake systems, chassis parts |

| Steel Pipe | Inner/outer wall preparation |

| Shipbuilding | Hull cleaning, coating prep |

| Infrastructure | Bridges, guardrails, rail maintenance |

| Foundry | Sand removal, surface smoothing |

At Hitech-China, our steel pipe internal and external blasting systems are some of our most requested solutions. We customize them for different pipe diameters and capacities, offering full-coverage cleaning and dust control.

How Shot Blasting Supports Quality and Compliance

In regulated industries, “good enough” isn’t good enough. Non-compliant finishes can mean product rejection or even failure in the field.

High-standard shot blasting ensures your surfaces meet ISO, ASTM, and NACE specifications, guaranteeing consistency, cleanliness, and durability.

Compliance Standards & Shot Blasting Role:

| Standard | Requirement | Shot Blasting Function |

|---|---|---|

| ISO 8501 | Surface prep grades (Sa2.5 / Sa3) | Removes rust and scale to precise level |

| ASTM D4285 | Cleanliness before coating | Removes oil, grease, particles |

| NACE SP0178 | Weld zone surface conditions | Prepares roughness, removes slag |

Our machines come with media monitoring, abrasive flow control, and closed-loop systems to ensure consistent, certifiable results with every batch.

Choosing the Right Shot Blasting System

A poor machine match is like wearing the wrong-sized shoes—uncomfortable, inefficient, and potentially costly.

Choosing the right shot blasting machine depends on material, geometry, production rate, and surface requirements. Custom systems are ideal for heavy or unique parts.

Here’s what I always evaluate with clients:

- Material Type: Carbon steel, aluminum, cast iron?

- Part Geometry: Pipes, plates, irregular shapes?

- Production Volume: Tons per hour? Batch size?

- Surface Finish Requirements: What roughness grade?

- Automation Needs: Fully automated or semi-manual?

System Types Overview:

| System Type | Suitable Parts | Typical Use at Hitech-China |

|---|---|---|

| Roller Conveyor | Plates, beams, profiles | Tower fabrication, steel structures |

| Rotary Table | Castings, odd shapes | Foundry and job shop applications |

| Pipe Inner/Outer Blasting | Tubes, oil & gas pipelines | Our specialty—custom pipe solutions |

| Mobile Shot Blaster | Roads, bridges, on-site cleaning | Infrastructure maintenance |

We engineer each machine to optimize nozzle angles, blast intensity, and abrasive selection—ensuring both surface quality and machine longevity.

Conclusion: The Strategic Value of Shot Blasting

In manufacturing, great finishes start before the paint ever touches the surface. Your quality, efficiency, and customer satisfaction all begin with surface prep.

Shot blasting is not just a process—it’s a strategy for reliability, performance, and long-term ROI.