In industrial operations, downtime is your worst enemy. When your shotblasting machines break down, the costs pile up—lost productivity, mounting repairs, and the damage to your reputation. The solution to all these challenges? High-quality shotblast spares. These parts are more than just replacements; they are your investment in long-term performance, efficiency, and reliability.

If you want your operation to run smoothly, the importance of using top-grade spares cannot be overstated. Inferior parts may seem like a bargain upfront, but they will cost you much more in the long run—through costly downtime, increased maintenance, and the risk of damage to your equipment.

What are Shotblast Spares?

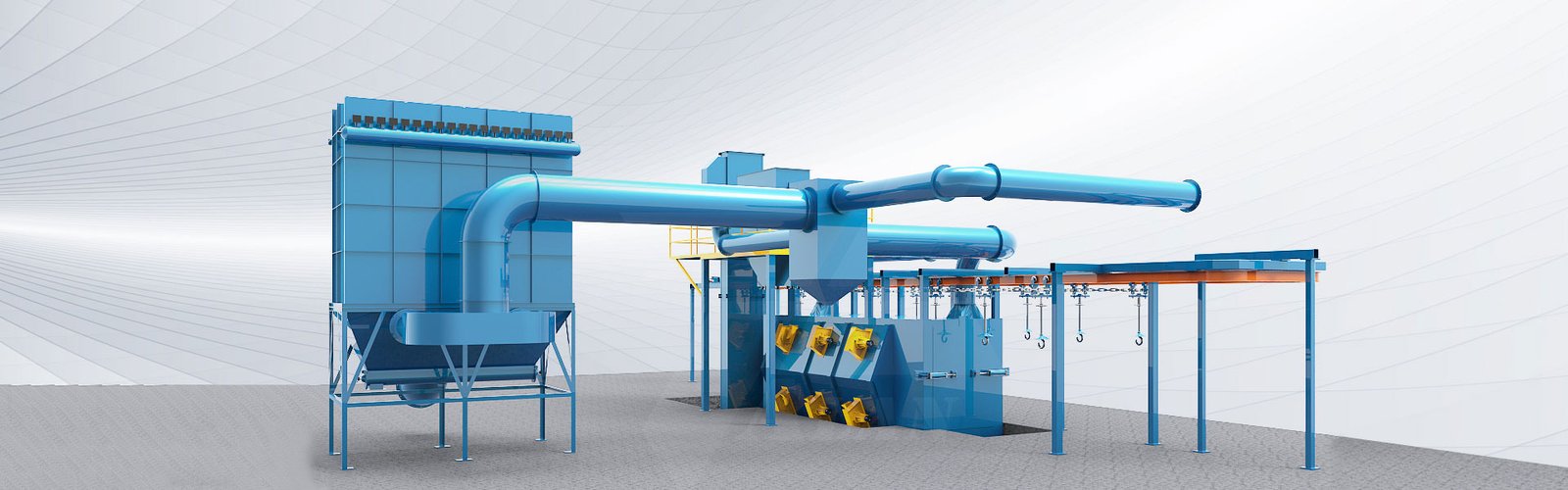

To understand why quality matters, let’s first take a look at what shotblast spares are and why they’re indispensable to the process.

Key Components of a Shotblasting System

- Blast Wheels: These are responsible for propelling abrasives onto the surface. Poor-quality blast wheels wear out faster, reducing cleaning efficiency.

- Liners and Control Cages: Protect your equipment from abrasive wear while ensuring the right distribution of abrasives. Low-quality liners break down quickly, leading to inconsistent results.

- Elevator Belts and Impeller Heads: Vital for moving and controlling abrasives. Cheap parts may fail sooner, causing system malfunctions and unnecessary delays.

These spares are at the heart of your shotblasting operations. If any one of them fails or performs poorly, your entire system suffers.

The Hidden Cost of Cheap Spares

It’s tempting to go for cheaper options, but let’s get to the point: cheap spares cost you more in the long run.

The True Cost of Inferior Parts

| Problem | Cheap Spares | High-Quality Spares |

|---|---|---|

| Breakdown Frequency | More frequent breakdowns | Fewer breakdowns, more reliability |

| Maintenance Needs | Higher maintenance and repair costs | Lower maintenance costs |

| Downtime | Extended downtime, lost production | Reduced downtime, higher output |

The fact is, low-cost spares won’t keep your machines running at their best. Frequent breakdowns, costly repairs, and longer downtime can drain your resources and halt your production. High-quality spares, however, give you reliable performance, fewer disruptions, and ultimately—more profit.

High-Quality Spares = Better Efficiency

Your machines are only as efficient as the components that power them. Low-quality parts drag your system down, leading to inconsistent results and reduced productivity. Here’s why quality spares are critical to efficiency:

Benefits of Investing in Quality Spares

- Consistent Results: High-quality spares ensure a consistent, thorough cleaning process, improving the quality of your output.

- Increased Productivity: With fewer breakdowns and repairs, your machines stay in operation longer, increasing overall productivity.

- Client Satisfaction: Consistently high-quality results lead to better customer satisfaction and repeat business.

With high-quality spares, your shotblasting machines will operate more efficiently, minimizing downtime and maximizing productivity. This means more work done, with fewer headaches.

Ensuring Safety and Reliability

Every breakdown doesn’t just cost you money—it can put your team at risk. Poor-quality spares can cause machinery malfunctions that lead to serious accidents. Safety isn’t just a priority; it’s essential.

Protecting Your Operations and Workforce

- Reduced Risk of Malfunctions: High-quality spares help prevent unexpected breakdowns, which can lead to costly accidents or worse.

- Fewer Injuries: Reliable parts help prevent the sudden failures that could cause injuries, ensuring your employees stay safe on the job.

When you invest in top-tier shotblast spares, you're not just protecting your equipment—you're protecting your workforce and your bottom line.

How to Choose the Right Shotblast Spares

Choosing the right parts isn’t just about picking the most expensive ones. It’s about finding the right balance of quality, compatibility, and long-term support.

Factors to Consider When Purchasing

- Compatibility: Ensure the parts are designed specifically for your system. Using incompatible parts leads to inefficiency and breakdowns.

- Manufacturer Reputation: Look for reputable suppliers with a proven track record. They offer parts you can trust to deliver consistent performance.

- After-Sales Support: Choose a supplier who offers comprehensive after-sales support to ensure long-term reliability.

When you’re sourcing shotblast spares, think beyond the immediate purchase. Long-term performance, reliability, and service support are the key factors that will save you from future headaches.

Conclusion

The importance of using high-quality shotblast spares cannot be emphasized enough. They are not just replacements for broken parts—they are the foundation of a more efficient, safe, and productive operation. By opting for quality, you safeguard your equipment, reduce downtime, and increase profitability.

Don’t settle for cheap spares. Your operations, safety, and bottom line depend on it.