Foundry machinery is a crucial part of modern metalcasting processes, offering innovations that significantly enhance productivity, precision, and efficiency. With rapid technological advancements, foundry equipment has become more versatile, adaptive, and energy-efficient, transforming the metalcasting industry.

Foundry machinery plays a pivotal role in improving the quality and efficiency of metal casting. As the industry has evolved, the machinery has advanced to meet the growing demands for higher precision, better productivity, and greater versatility. By integrating cutting-edge technology, foundries can now achieve superior results while minimizing waste and energy consumption.

Introduction: Revolutionizing Metal Casting with Advanced Machinery

The Evolution of Foundry Machinery

Over the years, foundry machinery has undergone a remarkable transformation. What once involved manual labor and rudimentary equipment has now evolved into a high-tech industry supported by automated machines that provide unparalleled precision. As industries demand faster turnaround times and more complex castings, foundry equipment has adapted to these needs, introducing automation, energy-efficient systems, and advanced control mechanisms.

The evolution of [foundry machinery](Over the years, foundry machinery has undergone a remarkable transformation. What once involved manual labor and rudimentary equipment has now evolved into a high-tech industry supported by automated machines that provide unparalleled precision. As industries demand faster turnaround times and more complex castings, foundry equipment has adapted to these needs, introducing automation, energy-efficient systems, and advanced control mechanisms.

) is not just about enhancing the physical machines but also improving the processes they enable. For example, melting furnaces now come with better temperature control, while molding machines are equipped with pattern recognition and automated systems to streamline production. This evolution has allowed foundries to meet the increasing demands of modern manufacturing, especially in sectors like automotive, aerospace, and heavy machinery.

Why Choose Our Foundry Machinery?

Our [foundry machinery](Over the years, foundry machinery has undergone a remarkable transformation. What once involved manual labor and rudimentary equipment has now evolved into a high-tech industry supported by automated machines that provide unparalleled precision. As industries demand faster turnaround times and more complex castings, foundry equipment has adapted to these needs, introducing automation, energy-efficient systems, and advanced control mechanisms.

) stands out in the market due to its robust performance and advanced features designed to cater to the dynamic needs of the metalcasting industry. Whether you are casting ferrous or non-ferrous metals, our machinery provides versatility, efficiency, and high precision. We focus on delivering solutions that not only meet but exceed industry standards, offering machinery that integrates seamlessly into your production cycle, reduces operational costs, and enhances productivity.

Core Features of Our Foundry Machinery

State-of-the-Art Equipment

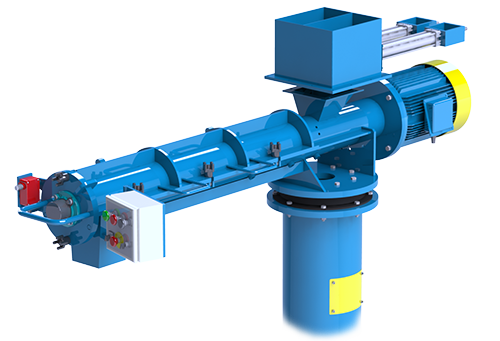

At the heart of our offering is a range of state-of-the-art equipment designed to handle the entire metalcasting process from start to finish. These machines include:

- Melting furnaces equipped with [energy-efficient](Over the years, foundry machinery has undergone a remarkable transformation. What once involved manual labor and rudimentary equipment has now evolved into a high-tech industry supported by automated machines that provide unparalleled precision. As industries demand faster turnaround times and more complex castings, foundry equipment has adapted to these needs, introducing automation, energy-efficient systems, and advanced control mechanisms.

) temperature control systems. - Molding machines with automated pattern recognition.

- Finishing tools optimized for high precision.

These machines feature adaptive control systems that allow for real-time adjustments to ensure optimal performance across various stages of metalcasting. The integration of such advanced features means that foundries can consistently produce high-quality castings, reducing the need for post-processing and minimizing waste.

Precision and Accuracy

Precision is crucial in metalcasting, and our machinery is engineered to provide exact, repeatable results. Our machines incorporate technologies that ensure high accuracy, ensuring that every casting meets the required specifications. This eliminates unnecessary rework and significantly reduces material waste.

By reducing the need for post-processing, our [foundry machinery](Over the years, foundry machinery has undergone a remarkable transformation. What once involved manual labor and rudimentary equipment has now evolved into a high-tech industry supported by automated machines that provide unparalleled precision. As industries demand faster turnaround times and more complex castings, foundry equipment has adapted to these needs, introducing automation, energy-efficient systems, and advanced control mechanisms.

) allows foundries to achieve near-perfect castings straight from the mold. This is particularly important in industries like automotive and aerospace, where even the smallest imperfections can lead to significant costs.

Efficiency at Every Step

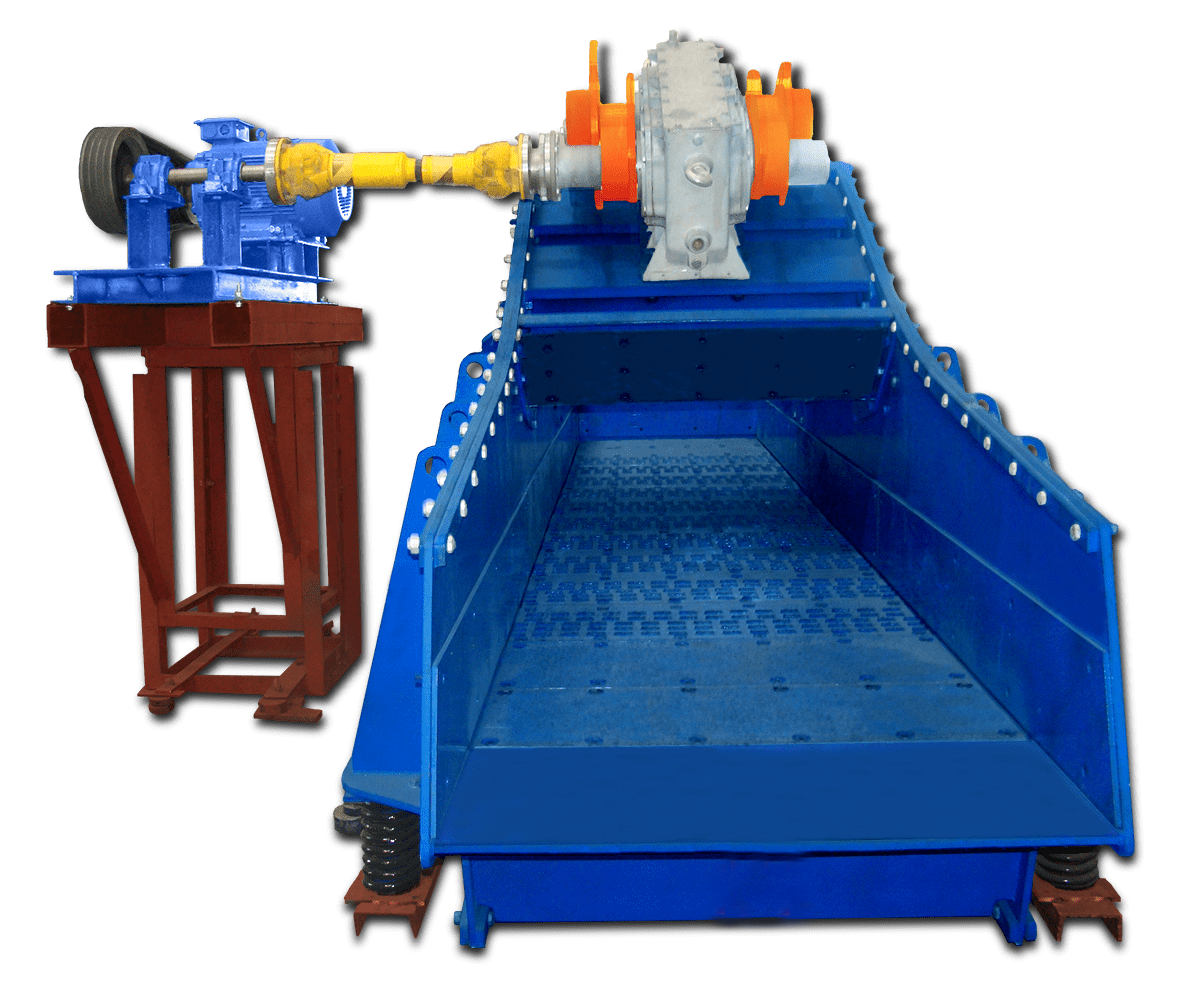

Efficiency is key in modern foundries, and our machinery has been optimized to enhance productivity at every stage of the casting process. From melting to molding to finishing, each step is designed to maximize output while minimizing resource consumption.

For instance, our melting furnaces are equipped with energy-saving features that significantly reduce electricity usage while maintaining high-performance levels. Similarly, the molding machines are designed to speed up production without compromising on quality. By improving efficiency at every step, we ensure that foundries can increase throughput and reduce costs, making them more competitive in the market.

Versatility: Meeting Diverse Casting Needs

Adaptability to Various Metals and Alloys

One of the standout features of our [foundry machinery](Over the years, foundry machinery has undergone a remarkable transformation. What once involved manual labor and rudimentary equipment has now evolved into a high-tech industry supported by automated machines that provide unparalleled precision. As industries demand faster turnaround times and more complex castings, foundry equipment has adapted to these needs, introducing automation, energy-efficient systems, and advanced control mechanisms.

) is its adaptability to different metals and alloys. Whether you're casting ferrous metals like steel or non-ferrous metals like aluminum, our equipment can handle a wide range of materials. This versatility makes our machinery ideal for foundries that work with diverse production needs and varying metal requirements.

Moreover, our machinery supports different casting techniques, such as sand casting and investment casting, allowing foundries to experiment with new methods and meet specific production requirements. This adaptability opens up new possibilities for innovation in casting techniques and allows foundries to diversify their offerings without the need for additional investments in new equipment.

Innovation and Capability Expansion

Our machinery is designed to foster innovation in the metalcasting industry. By enabling foundries to experiment with new alloys and casting methodologies, we help them stay ahead of the curve and meet the evolving needs of the market. The flexibility built into our systems allows for adjustments in casting techniques, whether to achieve higher precision, improve surface finish, or reduce material consumption.

This capability expansion is crucial in industries where new materials and complex shapes are increasingly in demand. By offering adaptable equipment that can accommodate new developments in metallurgy and casting technology, we ensure that foundries can keep pace with industry innovations and market trends.

User-Friendly Design & Safety Features

Intuitive Controls

The user experience is a top priority in our machinery design. We understand that ease of operation directly impacts a foundry's productivity. That’s why our machines are equipped with intuitive control systems that streamline operation and reduce the likelihood of errors. Operators can quickly learn the systems and make adjustments as necessary, which helps to increase operational efficiency and reduce downtime.

The user-friendly interfaces are designed to ensure that even complex processes are easy to navigate, allowing for smooth and efficient operations. This helps to minimize human error and ensures that the machinery operates at peak efficiency throughout the production cycle.

Comprehensive Training and Support

We are committed to providing our customers with the tools and resources they need to maximize the potential of our machinery. Our training materials, tutorials, and technical support ensure that operators are fully equipped to handle the equipment and troubleshoot any issues that may arise.

In addition to this, safety is a major focus in our machinery design. Every machine is built with safety features that protect operators and reduce the risk of accidents. We provide comprehensive safety protocols and regular updates to ensure a secure working environment, giving operators peace of mind while they work.

Elevating Your Foundry Operations with Cutting-Edge Technology

The Future of Metalcasting

As metalcasting continues to evolve, the demand for high-performance machinery grows. Our advanced foundry equipment plays a critical role in shaping the future of the industry. By integrating cutting-edge technology such as automated pattern recognition, adaptive control systems, and [energy-efficient](Over the years, foundry machinery has undergone a remarkable transformation. What once involved manual labor and rudimentary equipment has now evolved into a high-tech industry supported by automated machines that provide unparalleled precision. As industries demand faster turnaround times and more complex castings, foundry equipment has adapted to these needs, introducing automation, energy-efficient systems, and advanced control mechanisms.

) designs, we enable foundries to streamline their operations and achieve superior results.

Embracing these technologies not only improves operational efficiency but also helps foundries stay competitive in an increasingly globalized market. The future of metalcasting lies in innovation, and our machinery is designed to empower foundries to lead the charge.

Holistic Solutions for Foundries

We offer more than just individual machines – we provide complete, integrated solutions that cover the entire metalcasting process. From melting to molding to finishing, our machinery ensures a seamless production cycle, maximizing productivity and minimizing waste. By adopting our comprehensive solutions, foundries can significantly elevate their operations, boosting quality, efficiency, and overall performance.

This holistic approach enables foundries to focus on what truly matters – producing high-quality castings while reducing operational complexities. With our advanced machinery, foundries can meet the evolving demands of the market and achieve new levels of success.

Conclusion: Transform Your Foundry with Our Machinery

In conclusion, our foundry machinery represents a paradigm shift in how metalcasting operations are conducted. By embracing cutting-edge technology, foundries can streamline their operations, improve quality, and reduce costs, positioning themselves as leaders in the industry. With our robust, versatile, and energy-efficient equipment, you can transform your foundry operations and stay ahead of the competition.

It's time to embrace innovation, enhance your foundry's productivity, and achieve exceptional results with our advanced foundry solutions.