Tired of spending thousands on raw sand and struggling with disposal costs?

A resin sand molding recycling line reclaims used resin-bonded sand in foundries, significantly reducing raw material waste and improving operational efficiency.

Many foundries overlook the hidden goldmine of spent sand. If managed right, used sand can be your most valuable asset—not just waste.

What Is a Resin Sand Molding Recycling Line?

Recycling resin-bonded sand is more than just good housekeeping—it’s smart foundry economics.

A resin sand molding recycling line is a system that reclaims used resin-bonded sand so it can be reused in the molding process. It saves costs, reduces waste, and supports eco-friendly operations.

Resin sand molding is a popular process in metal casting due to its superior dimensional accuracy and strength. However, it generates a large amount of spent sand. Disposing of this used sand is costly and unsustainable.

A resin sand recycling line addresses this issue. It cleans and rejuvenates the sand by breaking it down, removing impurities, and preparing it for reuse. The result? Lower costs, less waste, and higher casting quality.

Why Resin Sand Recycling Is Important for Foundries?

Dealing with thousands of tons of used sand every year? You’re not alone.

Recycling resin sand helps foundries lower material costs, cut waste disposal expenses, and meet sustainability goals while maintaining high production efficiency.

Let’s face it: spent resin sand disposal is a growing headache for modern foundries. High dumping fees, tightening environmental regulations, and increasing raw sand prices are squeezing margins.

Here’s a quick snapshot:

| Problem | Impact |

|---|---|

| High raw sand cost | Drives up production expenses |

| Waste disposal limits | Legal risk and high landfill fees |

| Inconsistent sand quality | Affects casting precision and strength |

By investing in a recycling system, I’ve seen clients reclaim up to 95% of their sand, leading to remarkable savings and more stable operations.

Benefits at a Glance

- Reduce new sand purchases by 70–90%

- Improve casting quality with more consistent reclaimed sand

- Lower waste volume and associated handling costs

- Boost sustainability credentials—meet green manufacturing standards

This isn't just theory—our customers in Europe and Asia have documented over 25% improvement in overall casting consistency after adopting resin sand recycling systems.

How the Resin Sand Molding Recycling Process Works: Step-by-Step

The technology might sound complex, but the process is surprisingly logical.

The resin sand recycling process involves crushing, separating, scrubbing, and purifying used sand to make it ready for reuse in the molding system.

Let’s break it down step by step:

Step 1: Sand Crushing

Purpose: Break up large sand lumps formed during the molding and casting process.

- Equipment used: Lump crusher

- Output: Coarse granular sand

Step 2: Magnetic Separation

Purpose: Remove residual metal particles.

- Equipment used: Magnetic separator

- Output: Clean sand, free of iron or steel fragments

Step 3: Sand Scrubbing

Purpose: Strip away the hardened resin coating.

- Equipment used: Sand scrubber

- Output: Sand particles with minimal residual binder

Step 4: Dust Removal

Purpose: Extract ultrafine particles and dust that affect mold quality.

- Equipment used: Dust collector and cyclone separator

- Output: Finer and more consistent grain size distribution

Step 5: Thermal Regeneration (Optional)

Purpose: Burn off leftover resin binders completely.

- Equipment used: Thermal regeneration furnace

- Output: Virgin-like sand with excellent flowability and bonding strength

Step 6: Cooling and Storage

Purpose: Cool down the processed sand and store it safely for reuse.

- Equipment used: Sand cooler and storage silo

- Output: Ready-to-use reclaimed sand

Each of these steps is modular. Depending on your process requirements, you can design the line to be fully mechanical or include thermal stages for deeper resin removal.

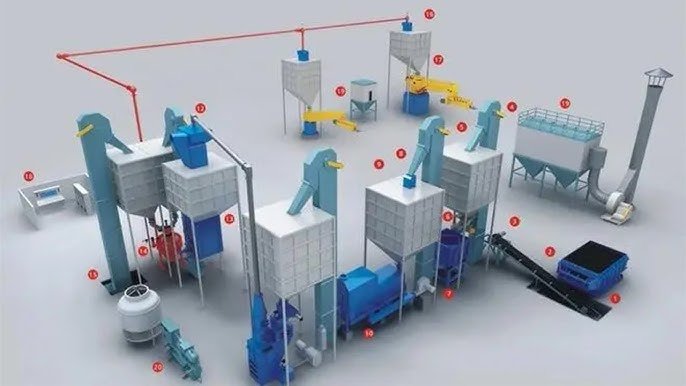

Core Components of a Resin Sand Recycling Line

You can’t optimize what you don’t understand—know your machines.

A standard resin sand recycling line includes crushers, scrubbers, separators, and storage systems, each playing a critical role in reclaiming usable sand.

Here’s a breakdown of the typical system components:

| Component | Function |

|---|---|

| Lump Crusher | Breaks sand blocks into granules |

| Vibrating Screen | Separates usable sand from oversize particles |

| Magnetic Separator | Removes metallic debris |

| Sand Scrubber | Cleans residual binder from sand surfaces |

| Thermal Regeneration Unit | Burns off deep-set resin for better purity |

| Dust Collector | Eliminates micro dust and fines |

| Sand Cooler & Silo | Ensures proper temperature and storage condition |

These parts can be customized based on your mold type, binder properties, and daily sand throughput.

Key Benefits of Using a Resin Sand Recycling System

Still wondering if it’s worth the investment?

A resin sand recycling line dramatically reduces costs, improves casting quality, and enhances sustainability in any metal casting operation.

Let’s make the value tangible:

| Benefit | Business Impact |

|---|---|

| Up to 90% raw sand reuse | Major cost savings |

| Consistent reclaimed sand | Improved mold strength and surface finish |

| Lower waste output | Eco-compliance and reduced disposal costs |

| Heat-resistant reclaimed sand | Better dimensional accuracy in cast parts |

| Streamlined operations | Less handling and transportation required |

In my experience, one of the hidden benefits is operator confidence—consistent sand means fewer defects, which makes every shift smoother and more predictable.

Applications Across Industries

This isn’t just for automotive—resin sand recycling fits a wide range of sectors.

Resin sand recycling systems are widely used in automotive, steel, marine, and heavy equipment foundries to enhance casting quality and efficiency.

| Industry | Common Applications |

|---|---|

| Automotive | Engine blocks, transmission housings |

| Marine and Shipbuilding | Propeller housings, anchor parts |

| Heavy Equipment | Cast frames, buckets, and motor casings |

| Railway | Couplings, wheel components |

| Construction Machinery | Load-bearing brackets, structural castings |

Wherever high-precision, large-volume castings are involved, reclaimed resin sand proves its value.

How to Choose the Right Recycling Line for Your Operation?

One size doesn’t fit all—let’s talk practical selection.

Choosing the right resin sand recycling line depends on your foundry’s daily output, floor layout, and sand quality requirements.

Here’s what to consider:

Key Selection Factors

| Criteria | What to Evaluate |

|---|---|

| Daily Sand Throughput | Match machine size and capacity |

| Plant Layout | Ensure easy integration and material flow |

| Binder Type | Some resins require thermal regeneration |

| Mold Complexity | More precise molds need higher sand purity |

| Automation Level | Consider IoT features and energy controls |

| Budget & ROI | Look at 3-year operational payback |

From my client installations, I’ve learned that thermal regeneration is best for high-spec casting needs, while mechanical systems work well for general-purpose foundries.

Conclusion: Is a Resin Sand Recycling Line Right for You?

A resin sand recycling line is more than an upgrade—it’s a transformation of how your foundry operates.

If you're spending too much on new sand and waste management, a resin sand recycling system can deliver cost savings, regulatory peace of mind, and quality consistency.

Reach out to us at Hitech-China for a custom assessment and see how you can reclaim your sand—and your profits.

FAQs

Can all resin sand be recycled?

Most resin-bonded sand can be recycled, especially with thermal regeneration. The success rate depends on binder type and contamination level.

What’s the difference between thermal and mechanical regeneration?

Mechanical scrubbing removes surface resin. Thermal regeneration burns off deeper binders, making sand almost like new.

How much maintenance does the system require?

Basic systems need weekly checks and monthly cleaning. Thermal units may require quarterly servicing.

**How long does it ta