Manufacturers face challenges in surface preparation—rust, scale, and contaminants impact product quality. Traditional methods are slow and labor-intensive, increasing costs.

A conveyor shot blasting machine automates surface treatment, ensuring efficiency, consistency, and cost savings. It enhances product quality and reduces labor dependency, making it ideal for modern manufacturing.

If you are considering whether a conveyor shot blasting machine fits your production needs, this guide will cover its principles, applications, and benefits.

What is a Conveyor Shot Blasting Machine?

Manufacturers struggle with inconsistent surface cleaning and labor-intensive processes. Manual blasting is slow and lacks precision, affecting productivity.

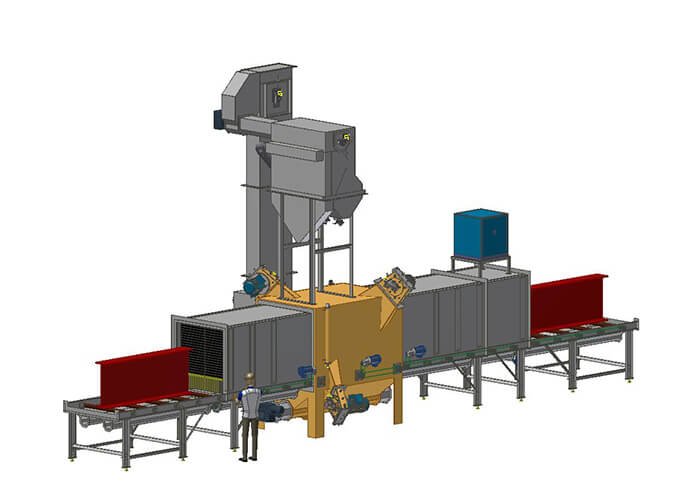

A conveyor shot blasting machine is an automated system that uses high-speed abrasive media to clean and prepare surfaces efficiently. It ensures uniform surface treatment and is ideal for large-scale industrial applications.

How Does It Work?

A conveyor shot blasting machine consists of a conveyor system, blast turbines, and a dust collection unit. Parts move through the blasting chamber, where high-speed abrasives clean the surface.

| Component | Function |

|---|---|

| Conveyor System | Moves workpieces through the blast chamber |

| Blast Turbines | Propels abrasive media at high speed |

| Dust Collector | Removes dust and contaminants |

Compared to manual or batch-processing methods, this system ensures uniform results and enhances productivity.

Key Applications: Where Is It Used?

Industries requiring rust removal, paint preparation, or surface strengthening struggle with inefficient cleaning methods.

Conveyor shot blasting machines are widely used in automotive, construction, and aerospace industries for efficient surface preparation.

Industry-Specific Benefits

- Automotive – Cleans chassis, frames, and engine components for enhanced durability.

- Construction – Prepares steel beams and rebar for better coating adhesion.

- Aerospace – Ensures precision cleaning for aircraft components.

Each industry benefits from increased efficiency, consistent quality, and reduced processing time.

Is a Conveyor Shot Blasting Machine Right for Your Business?

Manufacturers must evaluate cost, production scale, and material requirements before investing in new equipment.

If your business requires high-speed, consistent surface cleaning with minimal labor, a conveyor shot blasting machine is a strategic investment.

Key Considerations

| Factor | Manual Blasting | Conveyor Shot Blasting |

|---|---|---|

| Processing Speed | Slow | Fast |

| Consistency | Inconsistent | Uniform Results |

| Labor Intensity | High | Low |

If you process large volumes of metal parts or require precise surface treatment, this machine enhances efficiency and lowers costs.

Conclusion

A conveyor shot blasting machine offers automated, high-speed surface treatment for various industries. It improves quality, reduces labor, and enhances productivity. For manufacturers aiming for efficiency and consistency, this investment provides long-term value.

**