A drum-type shot blasting machine operates in a high-impact environment, continuously exposed to abrasive forces and mechanical stress. Without proper maintenance, issues like reduced efficiency, component wear, and unexpected breakdowns can lead to costly downtime.

Regular maintenance of a drum-type shot blasting machine ensures long-term efficiency, minimizes wear, and reduces operational costs. Key aspects include inspecting wear parts, maintaining the blast wheel system, managing dust collection, and ensuring proper lubrication.

By following a structured maintenance plan, businesses can extend the lifespan of their equipment and maintain optimal blasting performance.

Why is Maintenance Critical for a Drum Type Shot Blasting Machine?

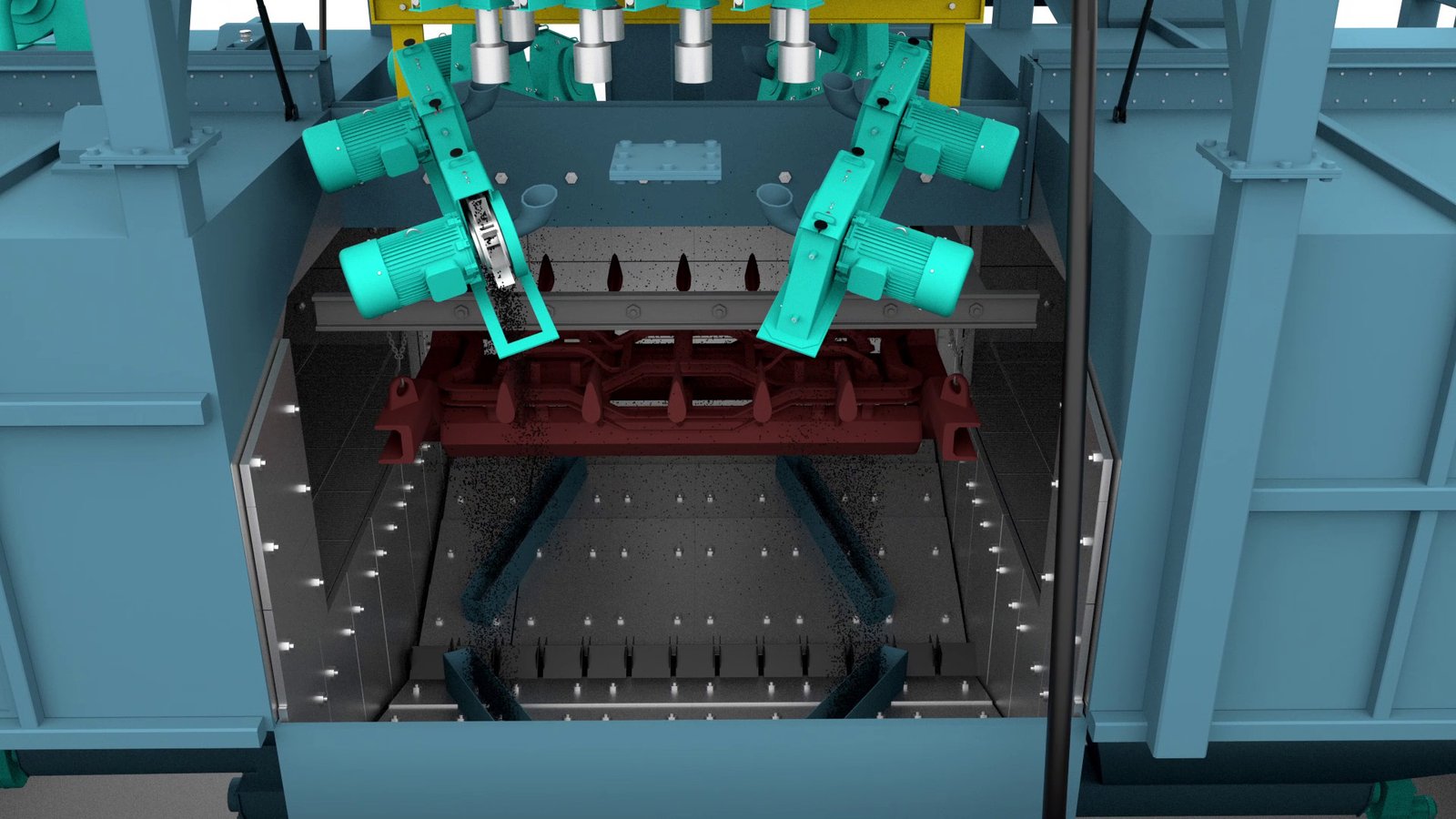

Drum-type shot blasting machines use a rotating drum to tumble workpieces while high-speed abrasive media cleans their surfaces. Over time, key components such as the blast wheel, liners, and dust collectors experience wear, impacting performance.

Proper maintenance prevents performance decline, ensures safety, and maximizes the machine’s operational lifespan. Regular servicing minimizes repair costs and avoids unexpected downtime, ensuring consistent surface treatment quality.

A well-maintained machine not only improves productivity but also ensures energy efficiency and compliance with industry standards.

Key Maintenance Aspects of Drum Type Shot Blasting Machine

1. Inspection and Replacement of Wear Parts

Drum-type shot blasting machines experience high levels of wear due to continuous exposure to abrasive materials.

Frequent inspection of wear components ensures the machine operates efficiently and prevents costly failures. Critical wear parts include the blast wheel, liners, and drum interior.

Common Wear Parts and Their Maintenance

| Component | Issue Signs | Maintenance Actions |

|---|---|---|

| Blast Wheel | Reduced blasting power, excessive vibration | Inspect for cracks, replace worn blades |

| Drum Lining | Visible wear, metal exposure | Replace when worn out |

| Nozzles & Pipes | Uneven abrasive flow | Clean regularly, replace damaged parts |

Regular wear monitoring reduces the risk of unexpected failures and prolongs component life.

2. Blast Wheel System Maintenance

The blast wheel is the heart of any shot blasting machine. A malfunctioning blast wheel can severely impact efficiency.

Proper alignment, regular balancing, and timely replacement of blades and control cages are essential for maintaining optimal blasting performance.

Best Practices for Blast Wheel Maintenance

- Check for imbalance – Misalignment can cause excessive vibration and reduce blasting efficiency.

- Replace worn blades – Blades lose effectiveness over time and should be replaced when signs of wear appear.

- Inspect bearings and seals – Ensuring proper lubrication extends bearing life and prevents breakdowns.

A well-maintained blast wheel significantly improves the uniformity of the blasting process.

3. Lubrication of Moving Parts

Lubrication reduces friction between moving parts, preventing premature wear and overheating.

Regular lubrication of drum bearings, blast wheel shafts, and conveyor mechanisms ensures smooth operation and extends component lifespan.

Key Lubrication Points

| Component | Lubrication Type | Recommended Frequency |

|---|---|---|

| Drum Bearings | High-temperature grease | Weekly |

| Blast Wheel Shaft | Oil-based lubricant | Every 100 operating hours |

| Conveyor Mechanism | Industrial grease | Monthly |

Using the correct lubrication type and adhering to schedules prevent mechanical failures and reduce maintenance costs.

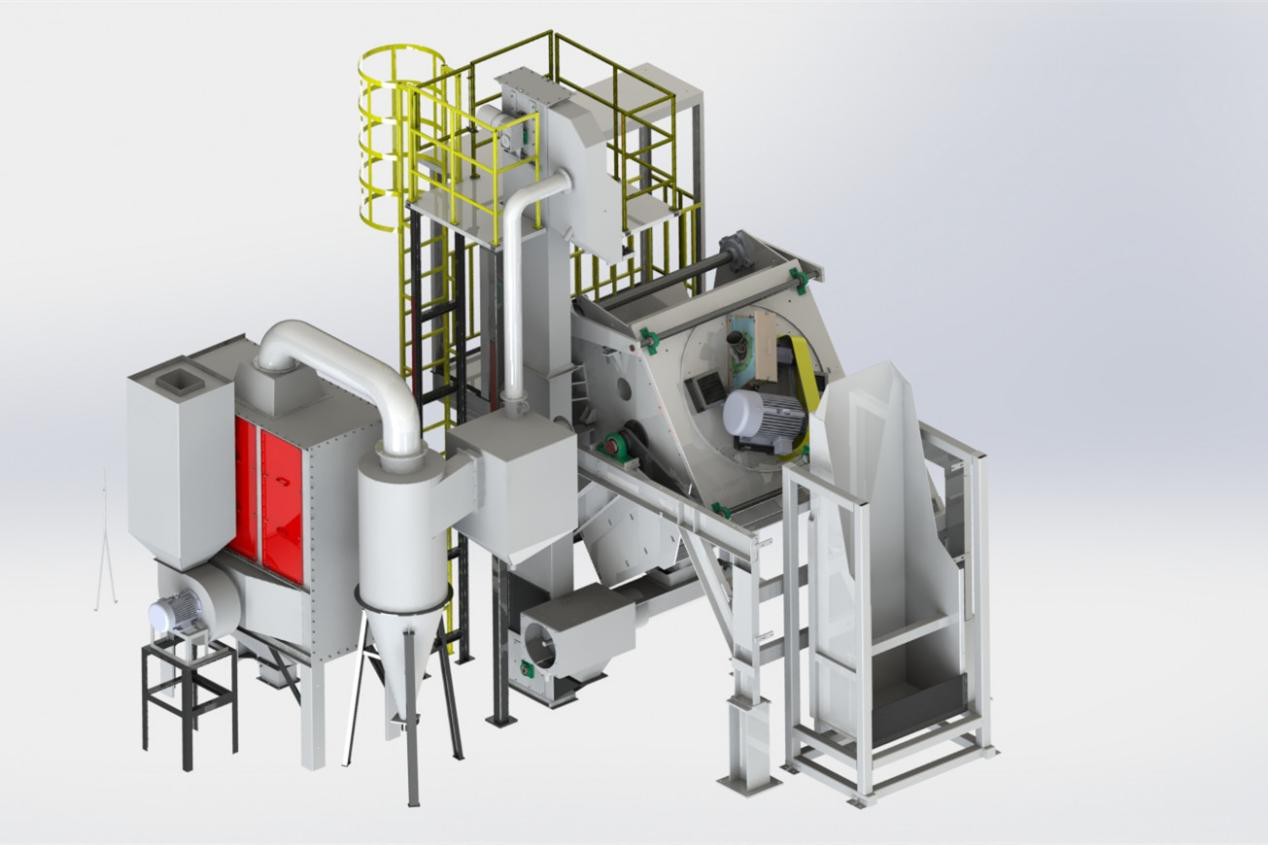

4. Dust Collection System Maintenance

The dust collection system plays a crucial role in maintaining a clean working environment and preventing contamination.

A poorly maintained dust collector can lead to excessive dust accumulation, reducing visibility and affecting machine performance.

How to Maintain the Dust Collection System

- Regularly inspect filter cartridges – Clogged filters reduce efficiency; clean or replace them as needed.

- Check ventilation ducts – Blockages can cause airflow issues, leading to dust buildup.

- Monitor air pressure – Proper airflow ensures effective dust extraction.

A well-maintained dust collection system improves operator safety and enhances the longevity of the machine.

5. Electrical and Control System Inspection

Drum-type shot blasting machines rely on an advanced control system for precise operation.

Routine checks of electrical connections, sensors, and automation systems ensure stable performance and prevent unexpected shutdowns.

Key Electrical Maintenance Practices

| Component | Potential Issue | Preventative Action |

|---|---|---|

| Sensors | Inaccurate readings | Clean and calibrate regularly |

| Wiring & Connections | Loose or frayed wires | Inspect and tighten connections |

| Control Panel | Software malfunctions | Update firmware and monitor performance |

A stable electrical system minimizes disruptions and enhances operational consistency.

Preventive Maintenance Schedule

Implementing a structured maintenance schedule helps ensure continuous, trouble-free operation.

| Maintenance Task | Frequency |

|---|---|

| Inspect blast wheel & replace worn parts | Weekly |

| Lubricate bearings and moving parts | Weekly |

| Clean and inspect dust collector | Bi-weekly |

| Check drum lining for wear | Monthly |

| Calibrate electrical components | Quarterly |

Following this schedule minimizes wear-related failures and improves machine efficiency.

Common Troubleshooting Tips

Even with regular maintenance, occasional issues may arise. Below are some common problems and their solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Uneven blasting | Worn blast wheel blades | Replace blades |

| Excessive noise | Loose components | Tighten all connections |

| Reduced suction in dust collector | Clogged filters | Clean or replace filters |

Proactively addressing these issues prevents major breakdowns and extends machine life.

Conclusion

Effective maintenance is essential for maximizing the lifespan and efficiency of a drum-type shot blasting machine. Regular inspection of wear parts, proper lubrication, dust collection system care, and control system checks ensure smooth operation and minimize downtime.

Investing in a structured maintenance plan not only enhances productivity but also reduces operational costs, ensuring long-term profitability for industrial applications.