Struggling with inconsistent sandblasting results or unexpected surface damage? You’re likely overlooking key process parameters.

The main parameters of sandblasting—media type and size, air pressure, nozzle type, stand-off distance, and more—determine surface quality, operator safety, and process efficiency.

When I consult with clients in industries like automotive or steel fabrication, the most common source of performance issues isn’t the machine itself—it’s improper parameter settings. Let’s dive into the variables that truly matter.

1. Abrasive Media Type and Size in Sandblasting?

Choosing the wrong abrasive media can destroy your part or deliver a poor finish. It’s the most common and most overlooked error in sandblasting.

The abrasive type and size affect surface roughness, cleanliness, and speed—making them central to sandblasting quality.

How Abrasive Type Affects Sandblasting Results

Different abrasives behave differently on metal, plastic, or composite surfaces. I’ve worked with clients who unknowingly used glass beads on hardened steel—resulting in minimal impact and wasted effort. Below is a comparison table I often reference:

| Abrasive Type | Hardness (Mohs) | Best Use Case | Reusability | Cost |

|---|---|---|---|---|

| Aluminum Oxide | 9 | Heavy-duty surface prep | High | Medium |

| Glass Beads | 6 | Polishing, light cleaning | Medium | Low |

| Steel Grit | 7–8 | Rust/paint removal on steel surfaces | Very High | Medium |

| Garnet | 7.5 | Environmentally friendly cleaning | Medium | High |

| Silicon Carbide | 9.5 | Etching on hard metals | Low | High |

The key is to match the abrasive’s hardness and shape to your material. For example, use angular aluminum oxide for aggressive stripping, but go for glass beads if you’re polishing stainless steel without roughening it.

Particle Size: Coarse vs. Fine Media

Fine media yields smooth finishes but lacks power. Coarse media strips fast but can scar delicate parts.

Coarse particles clean quickly but increase roughness. Fine media ensures precision but may require longer cycles.

| Particle Size (Mesh) | Application | Surface Finish | Material Suitability |

|---|---|---|---|

| 16–24 | Structural steel cleaning | Very rough | Heavy steel |

| 36–60 | Rust/paint removal | Medium | General metal |

| 80–120 | Light oxidation, polish | Smooth | Stainless, aluminum |

| 150–240 | Microfinishing, glass, jewelry | Very smooth | Non-ferrous, soft |

2. Air Pressure in Sandblasting and Its Impact?

Incorrect air pressure settings either waste abrasives or destroy parts. It’s a balancing act of force and finesse.

Air pressure governs blasting intensity. Higher PSI boosts speed, but risks warping or eroding surfaces.

Recommended Air Pressure Ranges for Different Applications

When setting up a shot blasting or sandblasting machine for a new client, I always start by calibrating the air pressure for the job. Here’s a typical PSI guide I follow:

| Application | Recommended PSI | Notes |

|---|---|---|

| Light Cleaning, Polishing | 30–50 PSI | Prevents surface damage |

| Paint/Rust Removal | 60–90 PSI | Efficient, safe for most metals |

| Heavy-Duty Surface Prep | 90–120 PSI | Aggressive, needs proper PPE |

Going above 120 PSI can cause over-blasting, which may deform thin materials or overly profile surfaces.

Effects of Low vs. High Air Pressure on Surface Finish

Low pressure underperforms on rust or paint. High pressure works fast but risks pitting or micro-cracks.

High pressure shortens cycles but can damage surfaces. Low pressure is safer but slower. Match PSI to material strength.

3. Nozzle Size and Type in Sandblasting?

The nozzle controls media flow and air volume—yet many operators never adjust it from factory settings.

Nozzle size determines flow rate and blast pattern; the material affects durability and cost-efficiency.

How Nozzle Diameter Influences Efficiency and Coverage

I once helped a client double their throughput just by switching to a larger-diameter tungsten nozzle. Here’s what I use as a reference:

| Nozzle Diameter (inch) | Coverage Area | Air Volume Required (CFM) | Ideal For |

|---|---|---|---|

| 1/8" | Very small | 15–30 CFM | Precision cleaning |

| 1/4" | Medium | 50–100 CFM | General-purpose blasting |

| 3/8" | Large | 100–200 CFM | Large-scale surface prep |

Nozzle Material and Wear Considerations

Wear rate is a silent cost in sandblasting. Cheap nozzles wear quickly and compromise results.

| Material | Wear Resistance | Cost | Use Case |

|---|---|---|---|

| Tungsten Carbide | Excellent | High | Long-term, high-volume blasting |

| Ceramic | Moderate | Low | Occasional or soft media use |

| Boron Carbide | Superior | Very High | Ideal for aggressive abrasives |

I advise heavy-use clients to invest in boron carbide, despite the cost. Over time, it’s cheaper than replacing ceramic nozzles every month.

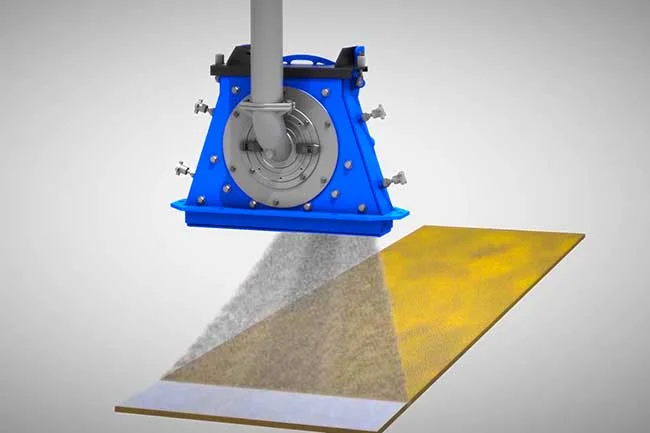

4. Stand-off Distance and Angle During Sandblasting?

Stand too close and you damage the part. Too far, and you waste abrasives. Most operators guess—bad idea.

Optimal stand-off ensures consistent cleaning without over-blasting or undercutting.

Optimal Distance for Consistent Results

I often recommend a stand-off distance of 6 to 12 inches, depending on the nozzle type and pressure. Too close? Risk of gouging. Too far? Media loses power.

Ideal Blast Angle for Different Surfaces

Blast angle affects erosion pattern and finish texture. 90° cleans deeper, 45° peels coatings efficiently.

| Blast Angle | Effectiveness | Best For |

|---|---|---|

| 90° | Maximum impact | Flat rust/scale removal |

| 45–60° | Gentle stripping | Coatings, paint, weld prep |

| <30° | Ineffective | Rarely used except in corners |

I use a 45° angle when cleaning welded automotive parts to avoid overcutting edges.

5. Blasting Time and Surface Dwell?

Over-blasting fatigues the surface and under-cleaning ruins coating adhesion. Timing must be precise.

Controlled dwell time ensures thorough cleaning without eroding the substrate.

How Exposure Duration Affects Surface Quality

Exposure time varies by pressure, media, and material. Visual cues are important, but I strongly recommend a timed system for repeatability. For example:

| Application | Typical Duration (per section) | Note |

|---|---|---|

| Paint Removal | 10–20 seconds | Use timer to avoid damage |

| Heavy Rust Removal | 30–60 seconds | Rotate part frequently |

| Precision Microblasting | 3–10 seconds | Visual inspection required |

6. Moisture and Contaminant Control in Sandblasting?

Moisture in media is a silent killer—it clogs lines and corrodes surfaces.

Dry media maximizes abrasive force and prevents nozzle blockages.

Why Dry Media Matters for Effective Abrasion

In humid environments, I always install inline dryers and media dehumidifiers. Moist media forms clumps, reducing flow and blasting consistency.

Surface Prep: Cleaning Before and After Blasting

Degreasing and drying the part before blasting prevents contamination. After blasting, I recommend a clean air blow-down and solvent wipe.

7. Equipment Type and System Configuration?

System type determines efficiency, scale, and maintenance needs. Choosing the wrong one wastes resources.

Suction systems are budget-friendly; pressure systems offer power. Cabinet setups suit precision; portable units handle large-scale jobs.

Suction vs. Pressure Blasting Systems

| System Type | Media Velocity | Best For | Cost |

|---|---|---|---|

| Suction | Low | Light-duty, fine work | Low |

| Pressure | High | Heavy-duty operations | Higher |

Pressure systems require more air but are twice as fast in aggressive cleaning.

Portable vs. Cabinet Sandblasters

| Configuration | Advantages | Ideal Use Case |

|---|---|---|

| Portable | Large surface coverage | Industrial parts, steel beams |

| Cabinet | Clean, enclosed environment | Small parts, precision tools |

8. Safety Parameters and Best Practices in Sandblasting?

Ignoring PPE and safety protocols can lead to severe health risks—especially silicosis.

Always use protective gear and follow ventilation and noise safety regulations.

PPE Requirements for Sandblasting Operations

I mandate the following for every job site:

- Helmet with air supply

- Full body blast suit

- Heavy-duty gloves

- Hearing protection

- Respirator (if open-air blasting)

Ventilation, Noise Control, and Operator Safety Tips

Use exhaust systems and dust collectors to control airborne particles. Limit shift lengths to reduce fatigue. Follow OSHA standards for industrial blasting.

FAQs About Sandblasting Parameters

Q: What’s the best abrasive for removing rust?

A: Steel grit or aluminum oxide—depends on the substrate hardness.

Q: Can I use regular air compressors for sandblasting?

A: Only for light-duty work. For sustained blasting, use high-CFM compressors.

Q: How do I reduce dust during sandblasting?

A: Use water-injection blasting or install dust extraction systems.

Conclusion

Understanding and adjusting sandblasting parameters—media, pressure, nozzle, distance, and safety—not only improves surface quality but also extends equipment life and ensures operator safety.