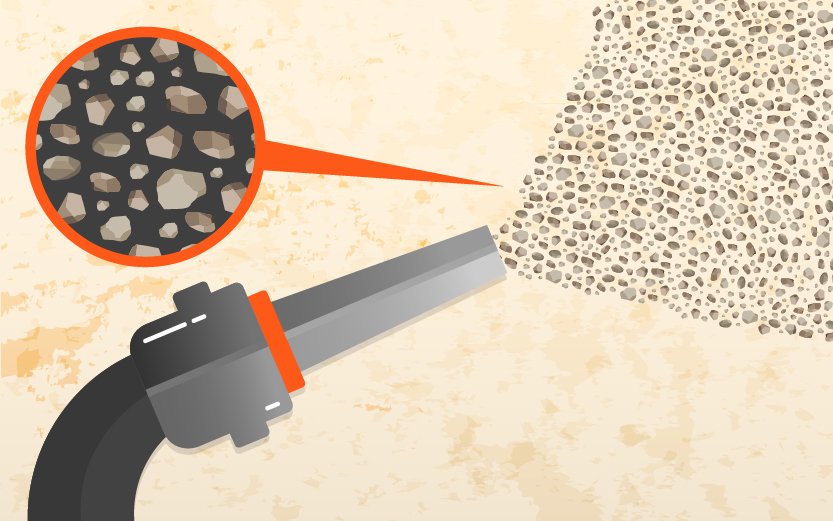

Grit blasting is a surface preparation method that involves propelling abrasive materials at a surface to clean, modify, or prepare it for further treatments. The selection of the correct abrasive material is crucial to achieving the desired outcome for different applications. Depending on the material, desired finish, and intended use, abrasives vary greatly. In this article, we will explore the four most common abrasives used in grit blasting and their specific applications.

Choosing the right abrasive for grit blasting is essential to achieving the optimal surface finish and cleaning efficiency. The most commonly used abrasives—Garnet, Aluminium Oxide, Glass Beads, and Chilled Iron—each offer unique properties suited for different materials and tasks. Garnet is highly versatile and widely used for general surface cleaning, while Aluminium Oxide is ideal for tough, industrial cleaning and non-ferrous metals. Glass Beads are perfect for delicate finishing and polishing, and Chilled Iron is best for aggressive cleaning in heavy-duty applications like steel and industrial machinery.

The Four Most Common Abrasives Used in Grit Blasting

1. Garnet: The Versatile Workhorse for Surface Cleaning

Garnet is a naturally occurring abrasive that stands out for its sharpness and effectiveness. It is commonly used for cleaning metal surfaces by removing rust, scale, and other contaminants. Garnet is available in various grades, making it adaptable for different surface finishes. Its semi-angular shape provides a good balance between cutting action and minimal surface damage, making it the preferred choice for most grit blasting applications.

Why Choose Garnet?

- Efficient Surface Cleaning: It removes contaminants such as rust, paint, and corrosion without damaging the base material.

- Versatility: Garnet can be used for a wide variety of metals and substrates, including steel, aluminum, and castings.

- Surface Profile Creation: It helps in creating a clean, rough surface ideal for coating adhesion or further treatments.

2. Aluminium Oxide: Precision and Durability for Industrial Applications

Aluminium Oxide is a synthetic abrasive known for its exceptional hardness, making it suitable for heavy-duty applications. Manufactured from bauxite, this abrasive is primarily used on non-ferrous metals and components that require precise cleaning and surface preparation without cross-contamination. Aluminium Oxide is highly recyclable, which makes it an environmentally friendly choice for industrial blast cleaning.

Why Choose Aluminium Oxide?

- Hardness: It’s perfect for cleaning tough surfaces like steel turbines, valves, and other critical components.

- Non-Ferrous Applications: Aluminium Oxide is ideal for non-ferrous metals, minimizing the risk of cross-contamination.

- Recyclability: Its ability to be reused multiple times makes it a cost-effective option in industrial environments.

3. Glass Beads: Polishing and Finishing for High-Precision Tasks

Glass Beads are spherical, smooth abrasives made from soda-lime glass, commonly used to impart a polished or lustrous finish to metal surfaces. When used in grit blasting, glass beads gently clean parts without causing any abrasive damage, making them ideal for applications that require a pristine finish or delicate cleaning.

Why Choose Glass Beads?

- Polished Finish: Glass Beads are perfect for imparting a polished, lustrous surface finish, making them ideal for cosmetic applications.

- Gentle Action: Its non-abrasive nature ensures that no damage occurs to sensitive surfaces.

- Ideal for NDT: Glass Beads are used in applications where components must undergo non-destructive testing, as they do not alter the material’s integrity.

4. Chilled Iron: Aggressive Cleaning for Heavy-Duty Applications

Chilled Iron is an abrasive made from recast fused iron, known for its toughness and aggressive cleaning action. It is typically used in applications that require the removal of heavy rust, scale, or debris from ferrous materials such as steel. Chilled Iron is highly effective for profiling surfaces and cleaning tough industrial parts.

Why Choose Chilled Iron?

- Heavy-Duty Cleaning: It is ideal for large-scale cleaning projects, such as preparing ship hulls, steel tanks, or pipelines.

- Surface Profiling: Chilled Iron is excellent for preparing metal surfaces for coatings or linings by creating a rough profile.

- Recyclability: Chilled Iron is durable and can be reused many times, making it a cost-effective choice for large-scale operations.

However, Chilled Iron should be avoided on non-ferrous materials, as it could lead to contamination, especially in applications where coatings are to be applied.

Conclusion: Choosing the Right Abrasive for Your Grit Blasting Needs

Each abrasive used in grit blasting—Garnet, Aluminium Oxide, Glass Beads, and Chilled Iron—offers distinct advantages tailored to different surface preparation needs. Selecting the right abrasive depends on the type of material being cleaned, the desired surface finish, and the specific requirements of your project.

For more information or a consultation, don’t hesitate to contact us today. We are here to help you with all your surface preparation needs.

One Response

不错不错