Industries relying on surface treatment face increasing pressure to improve efficiency, reduce costs, and meet environmental regulations. Traditional shot blasting methods often lead to high energy consumption and maintenance downtime.

Roller conveyor shot blasting technology is evolving with AI-driven automation1, energy-efficient blast wheels2, eco-friendly abrasives3, and modular designs. These innovations are transforming surface treatment, enhancing productivity, and reducing operational costs.

This article explores the latest advancements shaping the future of shot blasting technology.

Understanding Roller Conveyor Shot Blasting Machines

Shot blasting is a crucial process in industries like steel manufacturing, automotive, and construction, where surface preparation determines product durability and coating adhesion.

What is a Roller Conveyor Shot Blasting Machine?

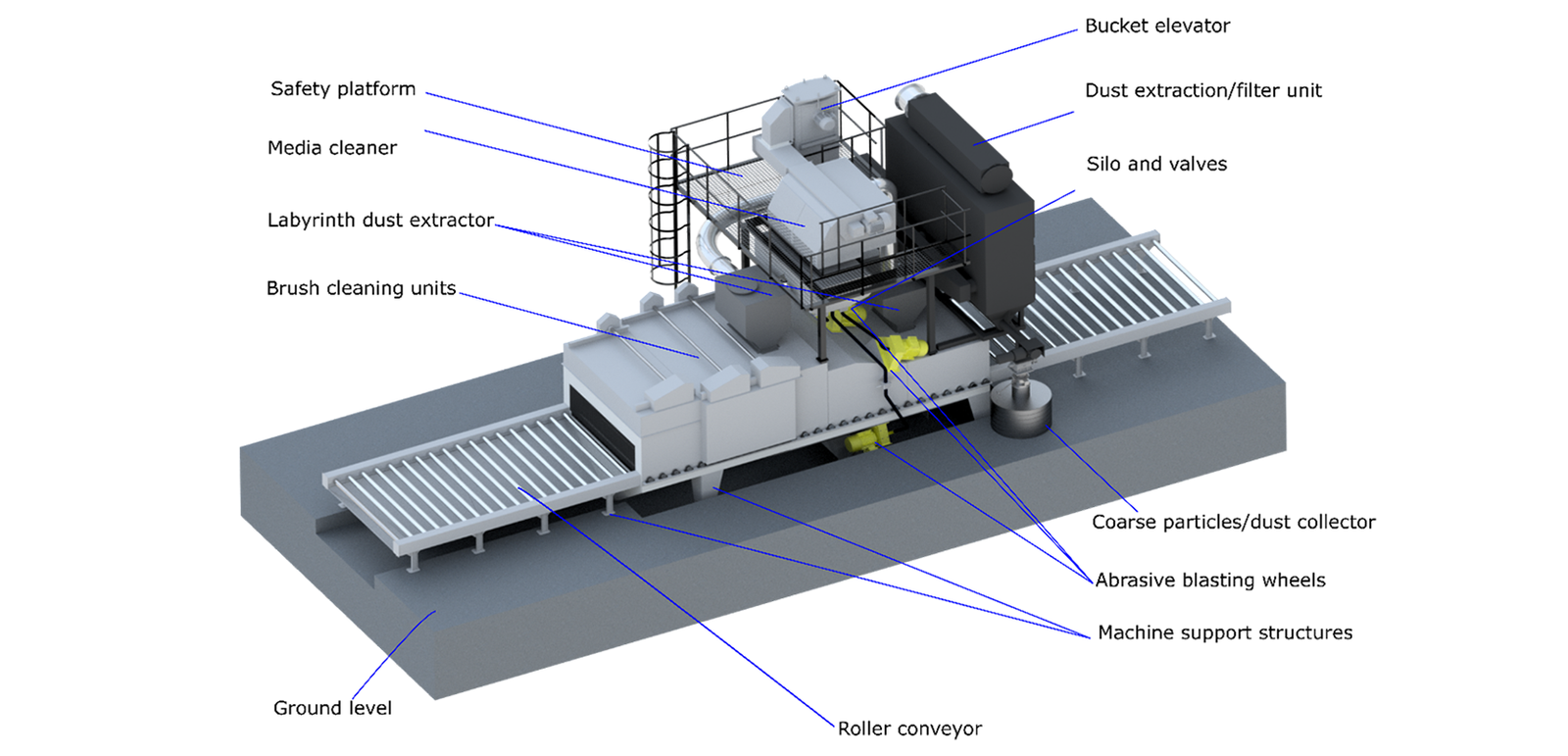

A roller conveyor shot blasting machine automates surface treatment by using high-speed steel shots to remove rust, scale, and contaminants.

How Does It Work?

- Material Loading – Workpieces move through a conveyor system.

- Blasting Chamber – Multiple blast wheels propel abrasives at high velocity.

- Abrasive Recovery – Used media is collected, cleaned, and recycled.

- Dust Collection – Filtration systems ensure a clean work environment.

- Finished Surface – The processed material is ready for coating or welding.

Industries That Rely on Roller Conveyor Shot Blasting

| Industry | Application |

|---|---|

| Automotive | Prepares chassis, frames, and engine parts. |

| Construction | Cleans steel beams and structural components. |

| Shipbuilding | Removes rust from large metal plates. |

| Steel Manufacturing | Enhances surface adhesion for coatings. |

Current Challenges in Shot Blasting Industry

Many manufacturers face obstacles when using traditional shot blasting machines.

Key Challenges in the Industry

- High Energy Consumption – Older blast wheels consume excessive power.

- Frequent Maintenance – Wear and tear on components cause costly downtime.

- Inconsistent Blasting Results – Uneven cleaning affects coating adhesion.

- Lack of Automation – Manual monitoring increases labor costs.

- Environmental Concerns – Dust emissions and abrasive waste impact sustainability.

Cutting-Edge Innovations in Roller Conveyor Shot Blasting

New technologies are addressing these challenges, improving efficiency and sustainability.

1. AI and Smart Automation in Shot Blasting

- AI-powered sensors optimize blasting parameters in real time.

- IoT-enabled monitoring tracks wear and schedules predictive maintenance.

- Case Study: A steel fabrication plant reduced maintenance downtime by 40% using AI-integrated shot blasting systems.

2. High-Efficiency Blast Wheels and Media Recovery Systems

| Innovation | Benefit |

|---|---|

| Next-gen blast wheels | Reduce energy consumption by up to 20%. |

| Optimized media flow control | Enhances abrasive lifespan and lowers waste. |

| Efficient recovery systems | Recycles up to 95% of abrasives. |

3. Eco-Friendly Abrasives and Dust Control Technology

- Sustainable Abrasives: Bio-based and recyclable media reduce environmental impact.

- Advanced Dust Collectors: New filtration technology cuts dust emissions by 50%, improving workplace safety.

4. Customization and Modular Shot Blasting Solutions

- Modular designs allow easy expansion as production grows.

- Custom settings enable tailored surface treatment based on material specifications.

Business Benefits of Upgrading to New Shot Blasting Technology

Many businesses hesitate to upgrade due to cost concerns, but the long-term benefits outweigh the investment.

Key Benefits

| Benefit | Impact on Business |

|---|---|

| Increased Productivity | Faster processing, reducing cycle times by up to 30%. |

| Lower Operational Costs | Energy-efficient motors and optimized media use. |

| Improved Surface Quality | Consistent blasting ensures better adhesion. |

| Sustainability Compliance | Reduces abrasive waste and meets regulations. |

Future Trends and Predictions in Shot Blasting Technology

Shot blasting technology is rapidly advancing toward full automation and sustainability.

Emerging Trends

- Fully Automated Shot Blasting Factories – Robotics and AI-driven systems handle the entire process.

- 3D Scanning & Real-Time Quality Assessment – Ensures uniform surface treatment.

- Eco-Friendly Solutions – Abrasives made from sustainable materials reduce waste.

- Digital Twin Technology – Simulations predict wear and optimize machine performance.

How to Choose the Right Roller Conveyor Shot Blasting Machine for Your Business

Selecting the best machine depends on production needs and automation levels.

Key Factors to Consider

| Factor | Consideration |

|---|---|

| Production Capacity | How many workpieces need processing per hour? |

| Material Handling | Steel plates, pipes, or complex profiles? |

| Automation Level | Do you need smart sensors and IoT monitoring? |

| Energy Efficiency | Opt for models with low power consumption. |

| Maintenance & Support | Choose manufacturers offering reliable service. |

Checklist for Upgrading

✅ Assess current blasting inefficiencies.

✅ Compare automation and energy-saving options.

✅ Consider long-term cost savings and ROI.

✅ Ensure compatibility with future production expansion.

Conclusion

The future of roller conveyor shot blasting is driven by AI, energy-efficient systems, eco-friendly abrasives3, and modular designs. These advancements enhance productivity, reduce costs, and ensure compliance with sustainability standards.

Why Upgrade Now?

- Competitive Edge: Faster and more efficient production.

- Cost Savings: Reduced energy and maintenance expenses.

- Sustainability: Meet global environmental regulations.

Call to Action

Looking for cutting-edge shot blasting solutions? Contact us for expert consultation and tailored recommendations.

🚀 Explore our advanced roller conveyor shot blasting machines to future-proof your manufacturing process!

Discover how AI-driven automation can enhance efficiency and reduce costs in shot blasting processes, making your operations more competitive. ↩

Learn about the advantages of energy-efficient blast wheels, including reduced energy consumption and lower operational costs for your business. ↩

Explore the environmental benefits of eco-friendly abrasives and how they can help your business comply with sustainability regulations. ↩ ↩