In the manufacturing of steel and metal parts, surface finishing is not just a cosmetic touch—it is essential for ensuring product quality, durability, and performance. However, many manufacturers face challenges in selecting the right surface treatment method. For industries requiring high precision and quality finishes, finding an efficient and reliable solution is crucial. This is where rotary table shot blasting machines come in.

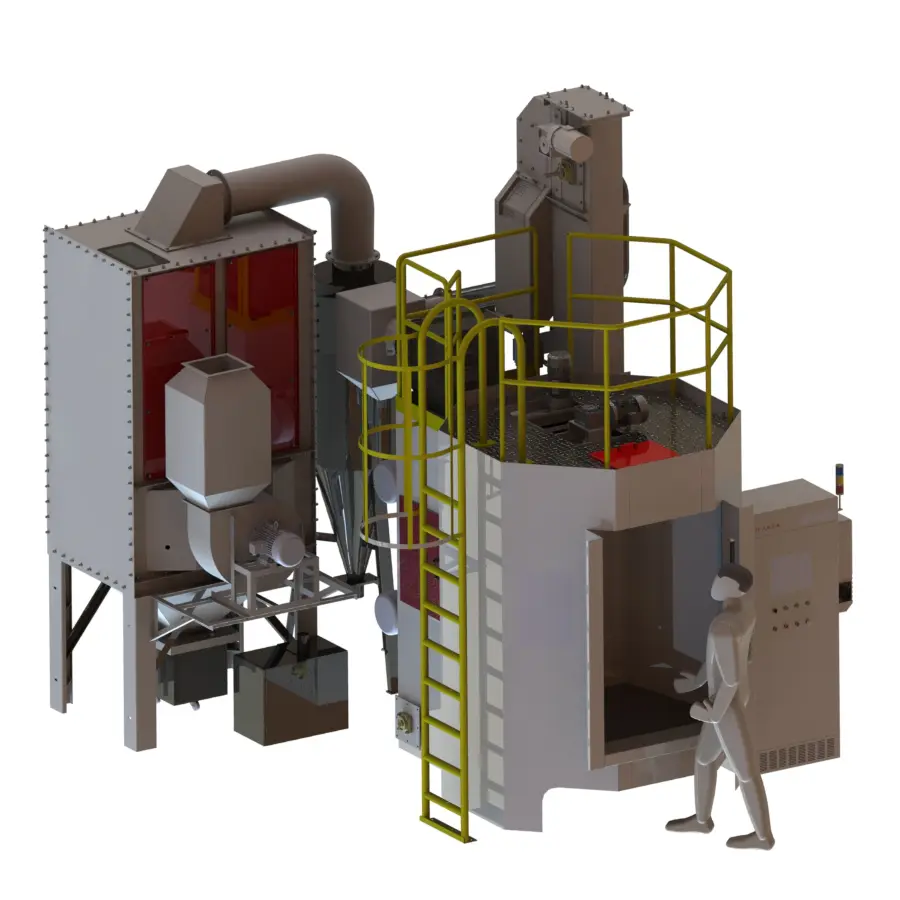

Rotary table shot blasting machines use high-speed abrasive blasting to efficiently and uniformly clean metal surfaces, removing rust, scale, and other contaminants to prepare parts for subsequent coating, painting, or welding.

How Do Rotary Table Shot Blasting Machines Improve Surface Finishing?

Traditional manual cleaning methods are slow and inconsistent, often failing to meet modern manufacturing demands for high-quality parts. Rotary table shot blasting machines solve this problem with their advanced working principle.

By utilizing a rotating table, these machines allow parts to be evenly exposed to abrasive media, ensuring uniform surface treatment and precision. Additionally, by using centrifugal force to propel the abrasives, the process becomes more efficient—not only cleaning the surface but also enhancing the part’s corrosion resistance and fatigue strength.

Key Advantages of Rotary Table Shot Blasting

| Advantage | Description |

|---|---|

| Efficiency | Processes large quantities of parts in a short time. |

| Uniformity | Provides consistent surface treatment, avoiding inconsistencies of manual cleaning. |

| Versatility | Suitable for various shapes and sizes of metal parts. |

| Enhanced Durability | Removes contaminants, increasing part lifespan and performance. |

| Cost Savings | Reduces manual labor and maintenance costs through automation. |

Why Is Surface Finishing Essential for Steel and Metal Parts?

Surface finishing is not just about aesthetics—it plays a critical role in enhancing the functionality of metal parts. Untreated surfaces are more susceptible to corrosion, oxidation, and even structural failures over time.

Shot blasting effectively removes contaminants and smoothens surfaces, improving adhesion for coatings, reducing friction, and enhancing corrosion resistance. This is particularly vital for industries such as automotive, construction, and marine applications, where durability is a top priority.

By using rotary table shot blasting machines, manufacturers can ensure their metal parts perform optimally even in the harshest conditions, leading to higher product quality and fewer defects.

Key Benefits of Surface Finishing

- Increased Corrosion Resistance – Reduces rust formation and oxidation.

- Better Coating Adhesion – Provides a clean, roughened surface for better paint and coating bonding.

- Improved Fatigue Resistance – Removes surface defects that could lead to cracks and part failures.

- Enhanced Mechanical Performance – A smoother, uniform surface reduces wear and tear over time.

How Do Rotary Table Shot Blasting Machines Enhance Productivity?

For most manufacturers, increasing production efficiency and reducing costs are key priorities. However, manual surface preparation is not only slow but also prone to inconsistencies, impacting both production speed and product quality. Rotary table shot blasting machines provide a more efficient and stable solution.

By automating the surface preparation process, these machines can handle large volumes of parts in less time while maintaining consistent quality. This improves production efficiency, reduces labor costs, and ensures that each part meets quality standards on the first pass.

How Rotary Table Shot Blasting Machines Improve Productivity

| Improvement | Impact |

|---|---|

| Faster Processing | Handles more parts in less time, significantly increasing throughput. |

| Reduced Rework | Provides uniform, precise surface finishing, minimizing rework needs. |

| Lower Labor Costs | Automation reduces reliance on manual labor, cutting operational costs. |

| Higher Production Capacity | Continuous operation reduces downtime, ensuring stable production. |

Conclusion

Rotary table shot blasting machines play an essential role in the surface finishing of steel and metal parts. They offer a highly efficient, uniform, and cost-effective solution for improving part durability, performance, and appearance. By automating the blasting process, these machines help manufacturers enhance productivity, reduce costs, and ensure consistent quality. For industries requiring precision and reliability, rotary table shot blasting machines are a game-changer in optimizing surface finishing and production efficiency.