As the new energy vehicle (NEV) industry rapidly expands, manufacturers face stricter quality requirements and increasing efficiency demands. Traditional metal treatment methods struggle to meet the lightweight, high-strength, and environmentally friendly requirements of modern NEVs.

Shot blasting plays a crucial role in NEV manufacturing by effectively removing oxidation layers, enhancing material surface strength, and improving coating adhesion, thereby increasing durability and safety.

This article explores the applications, benefits, and latest innovations in shot blasting technology for NEV production.

Why Is Shot Blasting Essential for NEV Manufacturing?

The lightweight design of NEVs requires the use of aluminum alloys, high-strength steel, and advanced composite materials. These materials must undergo strict surface treatment to ensure structural integrity and corrosion resistance.

Shot blasting efficiently cleans oxidation layers, strengthens materials, and optimizes subsequent coating or welding processes, making it indispensable in NEV production.

The Core Functions of Shot Blasting in NEV Manufacturing

| Application Area | Primary Function |

|---|---|

| Body Structure | Strengthens aluminum and high-strength steel, improving fatigue life. |

| Battery Enclosures | Removes oxidation layers, enhances welding quality, improves sealing. |

| Suspension Components | Removes surface residues, increases durability, ensures safety. |

| Brake Systems | Enhances friction surfaces, improves braking efficiency, reduces wear. |

By utilizing shot blasting, NEV components achieve longer service life and improved performance.

Shot Blasting in NEV Component Manufacturing

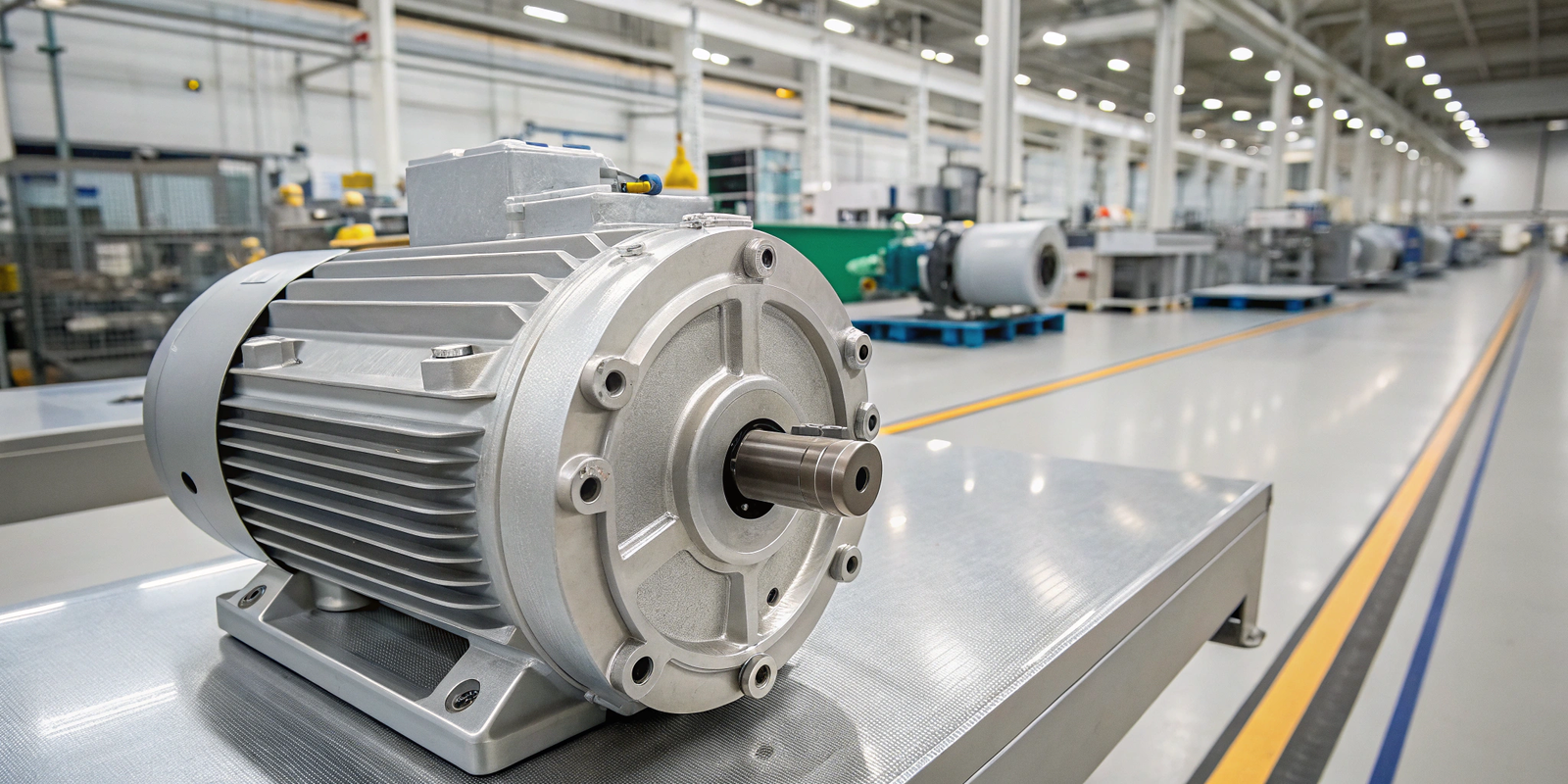

Key NEV components such as the body frame, battery enclosures, chassis, and motor housings require high-quality surface treatment to meet demanding performance standards.

Shot blasting provides uniform surface treatment, enhances mechanical strength, and optimizes coating adhesion, ensuring long-lasting durability and reliability.

Shot Blasting Applications for Key Components

Body Structure

- Treats aluminum body panels to improve fatigue resistance.

- Strengthens welded joints, enhancing vehicle rigidity.

Battery Enclosures and Frames

- Removes welding residues for better sealing performance.

- Ensures corrosion resistance, extending battery life.

Chassis and Suspension Parts

- Applies pre-stress treatment to improve impact resistance.

- Enhances coating adhesion, reducing wear and corrosion.

Brake Discs and Wheels

- Strengthens friction surfaces, improving braking efficiency.

- Prevents oxidation and increases durability.

With shot blasting, these critical components achieve higher safety and durability, making NEVs more reliable for consumers.

How Shot Blasting Improves NEV Component Quality

NEV components are often made from aluminum alloys, carbon fiber composites, and high-strength steel, requiring precise surface treatment methods that traditional machining or chemical processes cannot achieve.

Shot blasting efficiently removes surface contaminants while enhancing material fatigue resistance, making components stronger and more durable.

Key Benefits of Shot Blasting

| Benefit | Effect |

|---|---|

| Removes Surface Contaminants | Cleans oxidation layers, welding residues, and impurities. |

| Improves Coating Adhesion | Enhances the stability of painting and coating processes. |

| Increases Fatigue Strength | Strengthens surface layers to extend component lifespan. |

| Optimizes Dimensional Accuracy | Controls surface roughness to meet precision manufacturing needs. |

Since NEVs rely on lightweight materials, their surface treatment requirements are high. Shot blasting provides precise surface preparation, ensuring high-strength and long-lasting components.

Innovative Technologies: Smart Shot Blasting in NEV Manufacturing

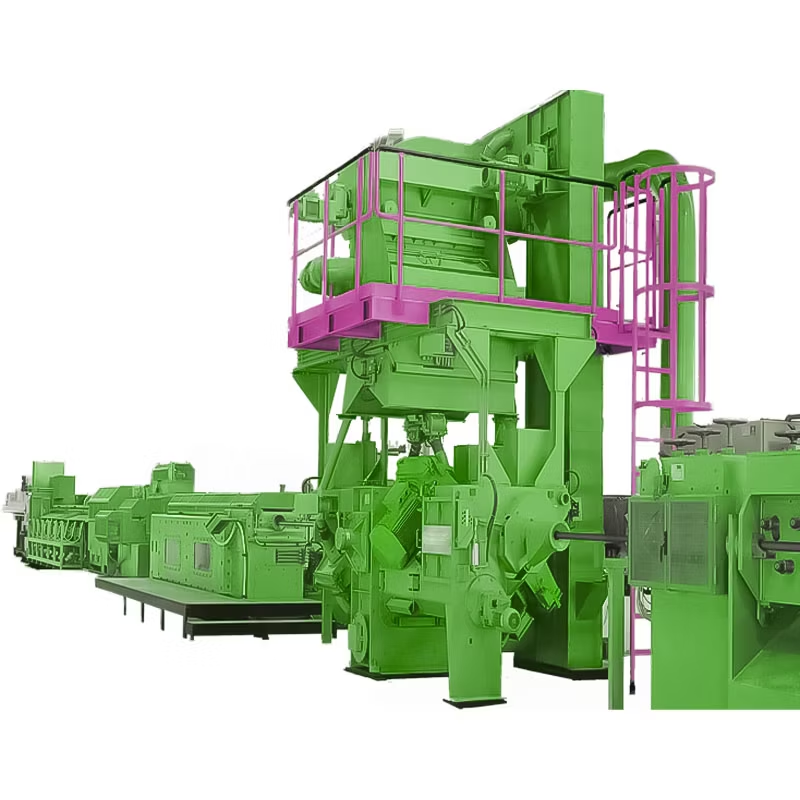

With the rise of Industry 4.0, smart shot blasting systems are being integrated into NEV manufacturing, enhancing production efficiency and quality control.

Automated shot blasting machines equipped with intelligent control systems, data monitoring, and robotic integration improve the precision and consistency of surface treatment.

Key Technologies in Smart Shot Blasting Systems

- Automated Shot Blasting Control – Utilizes PLC and HMI systems for precision control.

- Robotic Integration – Uses robotic arms to improve processing efficiency for complex components.

- Data Monitoring & Analysis – IoT technology tracks blasting results in real time, optimizing parameters.

- Energy-Efficient & Eco-Friendly Design – High-efficiency dust filtration systems reduce emissions.

These innovations ensure that NEV components receive high-precision, high-efficiency surface treatment while meeting environmental and safety standards.

Case Study: Shot Blasting for a Leading NEV Manufacturer

A globally recognized NEV manufacturer aimed to improve the durability of aluminum body panels and battery enclosures while optimizing production efficiency.

Solution Implemented:

- Automated shot blasting system for consistent surface treatment of aluminum components.

- Smart monitoring system to optimize blasting parameters in real time.

- Eco-friendly dust collection system to improve workplace safety and meet environmental standards.

| Before Optimization | After Optimization |

|---|---|

| Inconsistent coating adhesion | Even and stronger coating application. |

| Lower body durability | 30% increase in fatigue life. |

| Inefficient production | 20% boost in production efficiency. |

By implementing a smart shot blasting system, the manufacturer streamlined production, improved product quality, and reduced overall manufacturing costs.

Conclusion: Shot Blasting Drives High-Quality NEV Manufacturing

Shot blasting plays a crucial role in NEV manufacturing by enhancing component quality, optimizing surface treatment, and increasing production efficiency.

With advancements in automation and intelligent control, shot blasting technology will continue to improve NEV reliability and durability, supporting the industry's sustainable growth.

In the future, NEV manufacturers will increasingly adopt advanced shot blasting technologies to ensure product quality while meeting lightweight and environmental requirements, paving the way for further innovations in the automotive industry.