Your steel pipes are rusted, your coatings keep failing, and your workers are exhausted from endless manual cleaning.

Shot blasting solves all these problems in minutes — delivering a cleaner, stronger surface with zero chemicals and minimal labor.

You don’t need more acid, more scrubbing, or more frustration. You need a smarter, faster solution. Here's how shot blasting transforms rusty pipes into production-ready assets.

The Rust Problem That’s Costing You Time and Money

Rust isn’t just a surface issue. It’s a productivity killer — costing time, money, and your reputation.

Manual rust removal is slow, inconsistent, and often leaves behind residue that ruins coating adhesion.

| Problem | Impact |

|---|---|

| Manual grinding or brushing | Fatigue, high labor costs |

| Chemical rust removal | Hazardous waste, strict compliance burdens |

| Rust left under coatings | Peeling, corrosion returns quickly |

| Inconsistent finishes | Rejected pipes and customer complaints |

💬 “We used to spend hours cleaning each pipe. Our workers were exhausted, and still the finish wasn’t right.” — Fabrication Manager, Construction Supplier

If you’re still doing it by hand — you’re falling behind.

Why Shot Blasting Is the Ultimate Rust Removal Solution for Steel Pipes

Rust doesn’t stand a chance against steel shot moving at 80 m/s.

Shot blasting removes rust, oxides, and mill scale fast — and gives you a clean, adhesion-ready surface for coatings or welding.

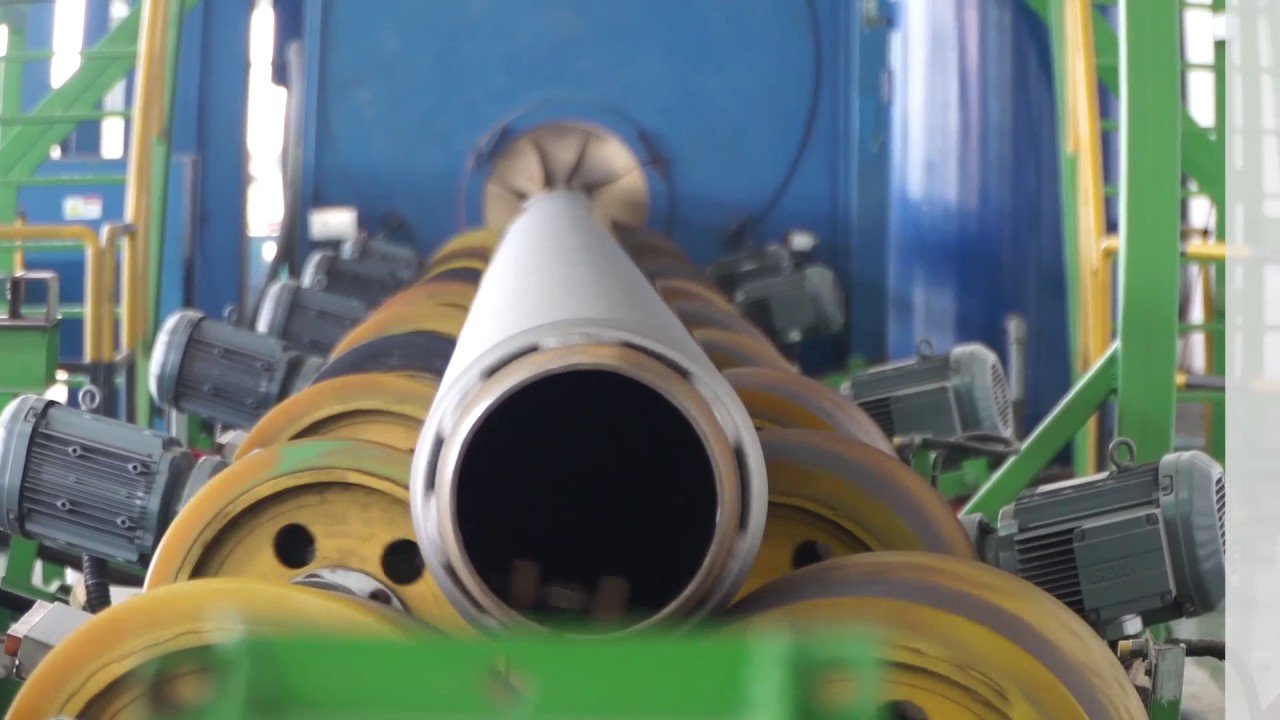

What Is Shot Blasting?

A mechanical process where high-speed steel shot or grit is projected onto the surface to remove rust, paint, and contaminants. It's clean, fast, and repeatable.

How It Works on Steel Pipes

- 360° turbine blast

- Automatic pipe rotation

- Consistent coverage of curved surfaces

- No chemical waste

The result? Pipes that are clean, profiled, and ready for the next process.

How Fast Is It? Rust Removal in Just Minutes

| Pipe Diameter | Rust Level | Machine Type | Time Required |

|---|---|---|---|

| 4" | Light | Inline Outer Blaster | ~2 minutes |

| 10" | Moderate | Internal + External Combo | ~5 minutes |

| 20" | Heavy | Rotary Table System | ~8–10 minutes |

⚡ One operator. Dozens of pipes. No mess. That’s Hitech-China speed.

The Step-by-Step Rust Removal Process Using a Shot Blasting Machine

Here’s how the full rust removal cycle works — from loading to inspection:

✅ Step 1: Pre-Check

Confirm pipe specs, check alignment, set parameters✅ Step 2: Load Into Machine

Use auto-centering rollers or load manually depending on system✅ Step 3: Blasting Begins

Turbines spin at high velocity, abrasives strip rust in seconds✅ Step 4: Dust Removal

Built-in vacuum system captures particles and clears the surface✅ Step 5: Inspection & Post-Treatment

Surface meets Sa 2.5 standard — ready for coating or welding

What Makes Pipe-Specific Shot Blasters More Effective?

Generic blasters are made for flat sheets. Pipes need purpose-built solutions.

Pipe-specific machines eliminate the limitations of traditional systems.

| Feature | Generic Blaster | Pipe-Specific System |

|---|---|---|

| Internal surface cleaning | ❌ Not possible | ✅ Built-in nozzles |

| Pipe rotation | ❌ Manual or none | ✅ Automatic, controlled |

| Media coverage | ❌ Uneven | ✅ 360°, turbine-angled |

| Pipe diameter adjustment | ❌ Manual configuration | ✅ Auto-adjustable rollers |

| Media recovery | ❌ Minimal | ✅ Full recycling system |

Pipes aren’t flat. Your blasting system shouldn’t be either.

Real Results: Before & After Shot Blasting

| Condition | Before Shot Blasting | After Shot Blasting |

|---|---|---|

| Visual | Brown/red rust patches | Clean metallic grey |

| Surface Profile | Uneven, flaky | Uniform, roughness Sa 2.5 |

| Coating Bond | Weak, prone to peeling | Strong, lasting adhesion |

| Time per Pipe | 30+ minutes manual | 3–5 minutes automated |

📸 [Add real before-and-after image if available]

Save Time, Cut Costs, and Get a Cleaner Finish

Every minute you spend manually cleaning pipes is time lost — and money burned.

Switching to automated shot blasting can reduce labor and cleaning time by up to 80%.

| Benefit | Impact |

|---|---|

| Faster cleaning | Higher output, meet delivery deadlines |

| Fewer reworks | Lower material & labor costs |

| Better adhesion | Longer-lasting coatings |

| Safer process | No acids, no fumes, cleaner environment |

✅ Regulatory compliance

✅ Safer operators

✅ Happier customers

Why Leading Pipe Manufacturers Trust Hitech-China

We’ve helped hundreds of manufacturers around the world streamline their surface preparation processes.

Here’s why they choose Hitech-China:

- 🛠️ Tailored Machines – Built for pipe sizes, coating types, and throughput targets

- 🌍 Global Reach – Exported to over 30 countries

- 👨🔧 Technical Support – Dedicated engineer consultation + full service plans

- 🧩 Modular Systems – Inline, rotary, and portable options available

We don’t sell machines. We deliver results.

🚀 Ready to Remove Rust — Fast, Clean, and Chemical-Free?

👉 Explore Hitech-China’s Pipe Shot Blasting Machines

📞 Contact our engineers for a free consultation

FAQ

Can shot blasting remove heavy rust?

Yes — especially with turbine-powered systems and angular steel grit. Even deep corrosion layers can be cleaned effectively.

Will it damage thin-walled pipes?

Not if settings are properly configured. Our machines offer pressure and media flow adjustments to protect delicate materials.

What’s the best abrasive for rust removal on pipes?

Steel grit is ideal for aggressive rust removal, while steel shot provides a more controlled surface profile.

✅ Download Now

“Steel Pipe Surface Prep: Fast Rust Removal Guide” – Free PDF