With increasingly strict global environmental regulations, the EU and US markets impose higher environmental requirements on industrial equipment. Traditional shot blasting machines face challenges in dust emissions, noise pollution, and energy consumption, and non-compliance may result in restricted market access.

To meet EU and US standards, shot blasting machines must adhere to strict dust emission, energy efficiency, and safety regulations while incorporating advanced eco-friendly technologies to minimize environmental impact.

This guide explores how shot blasting machines can comply with environmental regulations and optimize production efficiency.

What Are the Environmental Regulations for Shot Blasting Machines in the EU and US?

Environmental compliance for industrial equipment in the EU and US covers dust control, energy consumption, noise pollution, and waste management. Manufacturers looking to enter these markets must ensure their equipment meets the relevant regulatory and industry standards.

Shot blasting machines must comply with EU CE certification, US Environmental Protection Agency (EPA) standards, and Occupational Safety and Health Administration (OSHA) regulations to meet strict environmental compliance requirements.

Major Environmental Regulations and Standards

| Regulation/Standard | Region | Key Requirements |

|---|---|---|

| CE Certification (Environmental) | EU | Ensures dust and noise emissions comply with EU environmental standards. |

| EPA Air Emission Standards | US | Limits industrial dust emissions under the Clean Air Act. |

| OSHA Occupational Safety Standards | US | Protects workers from dust exposure, noise, and hazardous substances. |

| ISO 14001 Environmental Management | Global | Establishes systematic environmental management requirements. |

To comply with these regulations, shot blasting machines must incorporate advanced dust control, energy-efficient components, and noise reduction technologies.

How to Control Dust Emissions in Shot Blasting Machines?

Shot blasting produces a significant amount of dust, which, if not effectively controlled, can pose health risks to operators and contribute to environmental pollution. Dust control is a primary focus of EU and US environmental regulations.

High-efficiency dust collection systems, enclosed designs, and waste recovery technologies can significantly reduce shot blasting dust emissions, ensuring compliance with EU and US environmental standards.

Advanced Dust Control Technologies

High-Efficiency Cartridge Filtration Systems

- Uses HEPA or nano-filtration technology to capture fine particles.

- Filtration efficiency reaches 99.9%, meeting EPA air quality standards.

Fully Enclosed Shot Blasting Chambers

- Optimized sealing structures prevent dust leakage, improving workplace safety.

- Negative pressure control reduces dust dispersion and enhances efficiency.

Smart Monitoring Systems

- IoT technology enables real-time monitoring of dust concentration, automatically adjusting filtration settings.

- Data analytics optimize system efficiency, ensuring long-term compliance.

| Dust Control Method | Dust Reduction Efficiency | Regulatory Compliance |

|---|---|---|

| Traditional Fabric Filter | 80% | Basic compliance |

| HEPA Filtration System | 99.9% | EPA & OSHA certified |

| Smart Dust Monitoring | 99.99% | Exceeds EU/US regulations |

By implementing these technologies, shot blasting machines can effectively reduce emissions and meet EU and US environmental requirements.

How to Reduce Energy Consumption in Shot Blasting Machines?

Energy efficiency is a critical aspect of environmental compliance in the EU and US, where regulations such as the EU Ecodesign Directive and the US Energy Star Program set strict efficiency standards.

Optimizing the energy efficiency of shot blasting machines reduces operational costs while ensuring regulatory compliance.

Energy Efficiency Improvement Measures

High-Efficiency Motors & Variable Frequency Drives (VFDs)

- Utilizes IE3/IE4 high-efficiency motors to reduce energy consumption.

- VFDs adjust power output based on workload, achieving 20%-30% energy savings.

Smart Energy Management Systems

- Monitors energy usage in real-time to optimize operating times.

- Integrates with MES (Manufacturing Execution Systems) for remote energy tracking.

Kinetic Energy Recovery

- Implements efficient abrasive recovery systems to minimize new material consumption.

- Utilizes waste heat recovery to improve energy utilization and reduce carbon emissions.

| Energy Efficiency Measure | Energy Savings | Regulatory Compliance |

|---|---|---|

| Traditional Motor System | Standard Consumption | Non-compliant with Ecodesign Directive |

| IE4 Motor + VFD | 30% Reduction | Meets Ecodesign & Energy Star |

| Smart Energy Management + Heat Recovery | 40%-50% Reduction | Exceeds EU/US regulations |

Optimizing energy consumption allows shot blasting machines to reduce their carbon footprint while achieving compliance with EU and US efficiency standards.

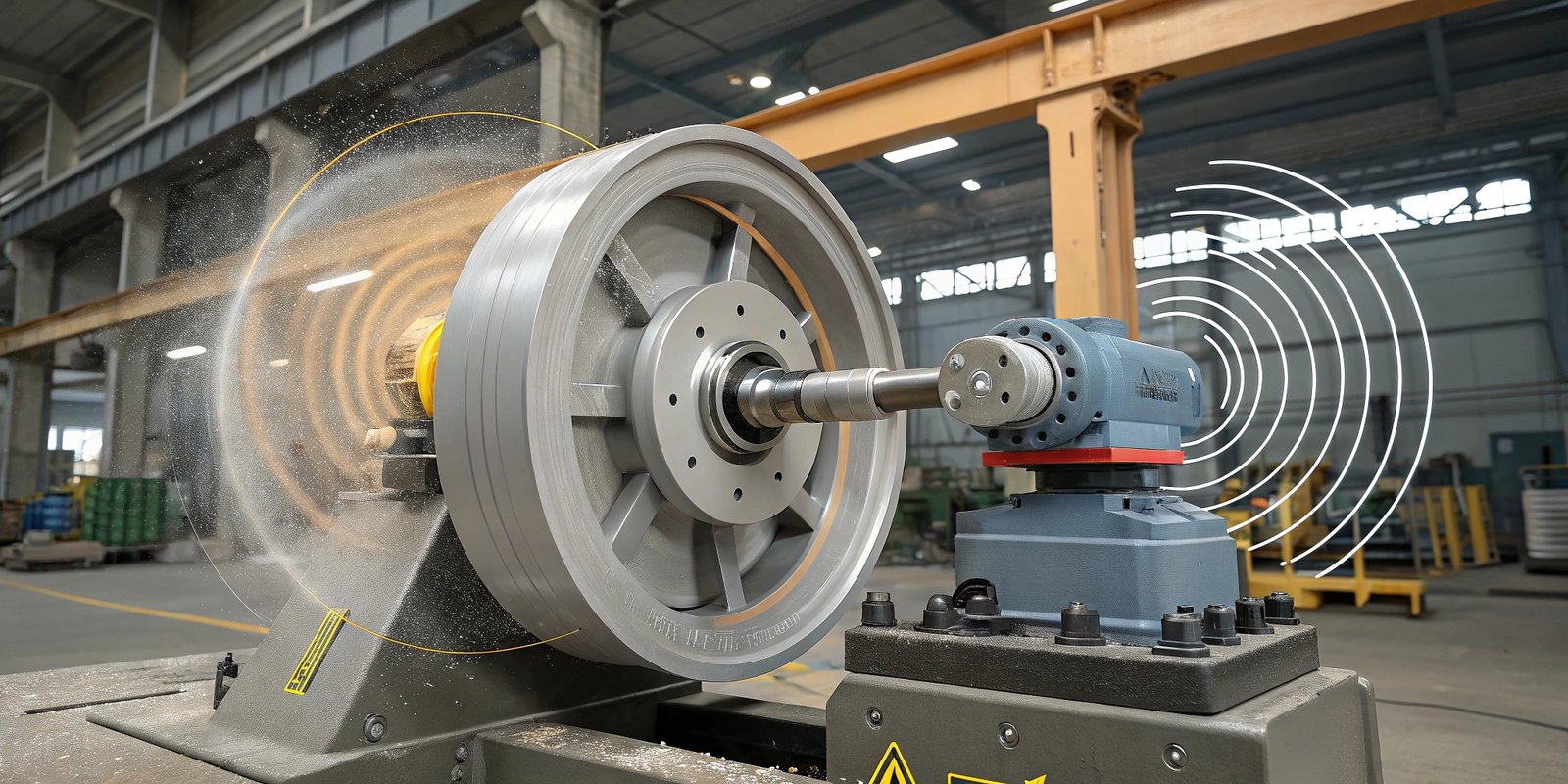

How to Reduce Noise Pollution in Shot Blasting Machines?

Shot blasting machines generate high noise levels, often exceeding 95 dB. EU and US occupational health regulations (e.g., OSHA) require workplace noise levels to remain below 85 dB to protect worker hearing.

By integrating soundproofing materials, silencers, and intelligent noise monitoring systems, shot blasting machines can effectively reduce noise levels to meet compliance standards.

Key Noise Reduction Measures

Soundproof Enclosures & Silencers

- High-density acoustic panels reduce noise propagation.

- Silencers installed in fans and vibratory screens minimize sound emissions.

Optimized Shot Blasting Wheel Design

- Low-noise blade technology reduces impact noise.

- Precision balancing minimizes vibration and noise levels.

Intelligent Noise Monitoring Systems

- Sensors track noise levels and adjust operational parameters in real-time.

- Remote noise monitoring ensures compliance with safety regulations.

| Noise Reduction Measure | Noise Reduction | Regulatory Compliance |

|---|---|---|

| Traditional Shot Blasting | >95 dB | Non-compliant with OSHA |

| Soundproof Enclosures + Silencers | 5-10 dB Reduction | Partially Compliant |

| Low-Noise Blasting Wheel + Smart Monitoring | 10-15 dB Reduction | Fully OSHA Compliant |

By implementing these noise control technologies, shot blasting machines create a safer working environment while ensuring compliance with occupational health regulations.

Conclusion: How to Ensure Shot Blasting Machines Meet EU and US Environmental Standards?

To comply with EU and US environmental regulations, shot blasting machines must be optimized in dust control, energy efficiency, and noise reduction.

By adopting high-efficiency filtration systems, smart energy management, and noise reduction technologies, manufacturers can achieve compliance, improve productivity, and reduce operational costs.

As environmental regulations continue to evolve, shot blasting machine manufacturers must invest in innovation to maintain compliance, support sustainability, and ensure a competitive advantage in global markets.