Many manufacturers struggle with achieving a clean and uniform surface finish on pipes before coating, welding, or further processing. Without the right equipment, surface contamination can lead to poor adhesion, premature coating failure, and increased maintenance costs.

Choosing the right pipe shot blasting machine ensures efficient rust, scale, and contamination removal, providing a uniform and clean surface for improved durability and performance.

However, selecting the ideal machine requires a careful assessment of several factors. Let’s explore the key considerations to help make the best decision.

Introduction

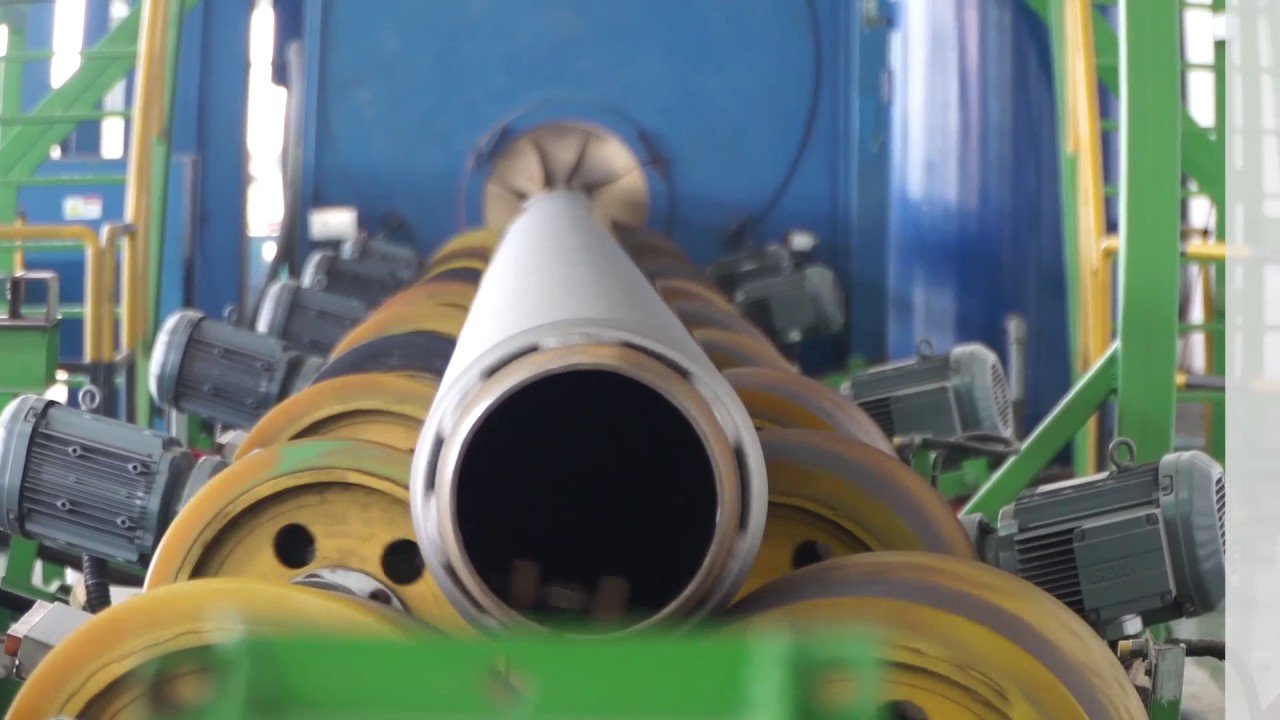

Pipe shot blasting is an essential process for cleaning and preparing pipes before coating, painting, or further processing. By using high-velocity abrasive particles, this method effectively removes rust, scale, and contaminants, ensuring a clean and uniform surface finish.

Selecting the right pipe shot blasting machine is critical to optimizing productivity and surface preparation efficiency. The wrong machine can lead to higher energy consumption, inadequate cleaning, and increased operational costs.

Why Is Proper Machine Selection Important?

A mismatch in machine capabilities and production requirements can result in:

- Excessive wear and tear, leading to frequent repairs

- Inconsistent surface cleaning, causing coating failures

- High energy consumption, increasing operational costs

- Downtime due to maintenance issues, slowing down production

By carefully evaluating technical specifications, abrasive selection, and maintenance needs, manufacturers can ensure cost-effective and efficient pipe cleaning.

Key Factors to Consider

Size and Capacity

The first and most crucial factor when selecting a pipe shot blasting machine is its ability to handle the required pipe sizes and production volumes.

| Factor | Consideration |

|---|---|

| Pipe Diameter & Length | Ensure the machine can handle the full range of pipe sizes processed. |

| Production Volume | Higher capacity machines improve batch processing efficiency. |

| Energy Efficiency | Avoid machines that are too large (wasting energy) or too small (causing bottlenecks). |

A properly sized machine ensures consistent performance, energy savings, and reduced downtime.

How to Choose the Right Size?

If processing large-diameter pipes, invest in a high-capacity machine with multiple turbines for fast and uniform cleaning. For small pipes used in precision applications, opt for a compact air-blasting system with precise control.

Type of Shot Blasting Process

Different shot blasting techniques are available, and selecting the most suitable one enhances efficiency and surface preparation quality.

| Shot Blasting Type | Best For | Advantages |

|---|---|---|

| Wheel Blasting | Large pipes with heavy rust or scale | Fast processing, high efficiency |

| Air Blasting | Small pipes, precise cleaning needs | Greater control over blasting intensity |

| Centrifugal Blasting | Medium to large pipes, continuous processing | Uniform surface treatment, lower abrasive consumption |

Each process has its advantages and limitations, depending on the material, contamination level, and required surface profile.

Which Blasting Process Is Best for Your Application?

- Wheel blasting is ideal for heavy-duty industrial applications where high-speed processing is required

- Air blasting is more precise, making it suitable for delicate materials or smaller pipes

- Centrifugal blasting offers continuous cleaning with lower abrasive waste, balancing speed and quality

Abrasive Selection

The choice of abrasive material significantly affects cleaning efficiency, surface finish, and cost-effectiveness.

| Factor | Details |

|---|---|

| Hardness | The abrasive should remove contaminants without damaging the pipe surface. |

| Shape | Rounded abrasives provide a smooth finish, while angular abrasives create a rough texture for better coating adhesion. |

| Size | Fine abrasives are ideal for light cleaning, while coarse abrasives remove heavy rust and scale effectively. |

Common Abrasive Materials Used in Pipe Shot Blasting:

| Abrasive Type | Best For | Characteristics |

|---|---|---|

| Steel Grit | Heavy rust removal | Angular shape, aggressive cutting action |

| Steel Shot | General cleaning | Spherical shape, smooth finish |

| Aluminum Oxide | Precision cleaning | Hard, reusable, suitable for delicate surfaces |

| Glass Beads | Surface finishing | Produces a satin-like finish, less aggressive |

Selecting the right abrasive improves cleaning efficiency, extends machine life, and ensures optimal surface preparation.

How to Optimize Abrasive Usage?

- Use recyclable abrasives to reduce operational costs

- Adjust abrasive size based on the required surface profile

- Monitor abrasive flow rate to maintain consistent cleaning performance

Maintenance and Support

Investing in a high-quality pipe shot blasting machine is only part of the equation; ensuring long-term reliability depends on maintenance and technical support.

| Consideration | Benefit |

|---|---|

| Ease of Maintenance | Machines with accessible components reduce downtime and operational costs. |

| Spare Parts Availability | Readily available replacement parts ensure continuous operation. |

| Technical Support | Reliable after-sales service, training, and troubleshooting assistance improve machine performance. |

How to Minimize Downtime and Maintenance Costs?

- Choose machines with modular components for easy replacement

- Ensure dust and abrasive separation systems are well-maintained to prevent clogging

- Work with manufacturers offering on-site training and remote diagnostics

Regular maintenance extends machine lifespan, reduces unexpected breakdowns, and ensures consistent performance.

Conclusion

Selecting the right pipe shot blasting machine is a critical decision that impacts cleaning efficiency, production quality, and operational costs. By evaluating:

✔ Size and capacity to meet production needs

✔ The best shot blasting process for specific applications

✔ Abrasive selection for optimal cleaning performance

✔ Maintenance and support for long-term reliability

A well-chosen pipe shot blasting machine will deliver superior surface quality, longer equipment lifespan, and a more efficient production process.