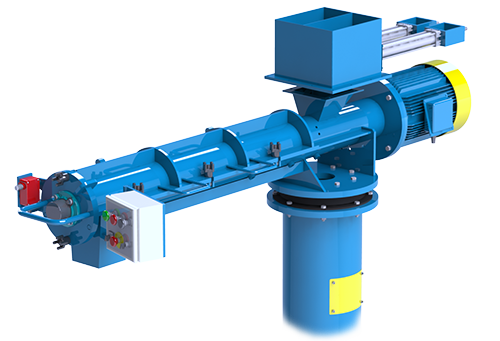

Resin sand mixers are integral to the metalcasting industry, where their durability directly influences the efficiency and longevity of production processes. Ensuring that these mixers remain in top condition through proper material selection and maintenance practices is critical to reducing downtime and increasing productivity.

Durability in resin sand mixers is not just about resilience but about optimizing operational efficiency and cost-effectiveness. In this article, we’ll explore the essential materials, maintenance strategies, and technological innovations that enhance the durability of these vital machines, helping foundries maximize their operational lifespan and performance.

Introduction: The Importance of Durability in Resin Sand Mixers

Why Durability Matters

- Resin sand mixers are crucial for creating the right mixture of resin and sand, forming the molds in metalcasting.

- The durability of these machines directly impacts production efficiency, equipment costs, and long-term performance.

- Durable mixers minimize downtime and maintenance costs, making them essential for sustained productivity.

Challenges Faced by Resin Sand Mixers

- Wear and tear due to continuous friction from abrasive materials.

- Exposure to high temperatures which can degrade materials.

- Chemical degradation from resin mixtures, causing corrosion and part failure.

Selecting the Right Materials for Resin Sand Mixers

Material Requirements for Resin Sand Mixers

- Resistance to abrasion: Materials must endure constant friction from sand and resin.

- High-temperature tolerance: Mixers often face extreme temperatures that require durable materials.

- Corrosion resistance: Chemical reactions from resin can cause corrosion, necessitating protective materials.

Best Materials for Durability

| Material Type | Key Benefits | Recommended For |

|---|---|---|

| Steel Alloys | High strength and wear resistance, ideal for high-stress environments. | Mixing blades, paddles, drive components. |

| Nickel Alloys | Excellent heat resistance and corrosion resistance. | Components exposed to high heat and corrosive environments. |

| Ceramic Coatings | Hard, durable layer that reduces wear and corrosion. | Mixing chambers, blades, and surfaces in direct contact with sand. |

| Polymer Composites | Wear-resistant and flexible, ideal for parts under moderate stress. | Specific components like seals or liners. |

Material Selection for Different Mixer Parts

- Mixing Blades and Paddles: Steel alloys or ceramic coatings are ideal for abrasion resistance and extending lifespan.

- Liners and Chambers: Corrosion-resistant steel alloys and polymer coatings can prevent chemical degradation.

- Drive Components: High-strength steel alloys are necessary for handling constant mechanical stress.

Maintaining Resin Sand Mixers for Longevity

Routine Maintenance Practices

- Regular Inspections: Scheduled checks help identify wear, corrosion, or damage before they lead to failures.

- Lubrication: Proper lubrication minimizes friction and wear, ensuring smoother operation.

- Cleaning: Regular cleaning prevents buildup that can interfere with performance.

Preventive Maintenance Methods

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Component Replacement | As needed (based on wear) | Prevents failure by replacing worn-out parts. |

| Surface Treatments | Periodic | Hardens surfaces to prevent abrasion and corrosion. |

| Seal Maintenance | Regular checks and replacements | Prevents leaks and ensures proper mixing. |

Addressing Common Mixer Failures

- Overheating: Caused by poor heat management or insufficient cooling, resulting in damage to components.

- Component Fatigue: Repeated stress can cause parts like paddles and gears to fail.

- Abrasive Wear: Constant friction between sand, resin, and components wears down parts.

Solutions to Extend the Lifespan of Critical Components

- Use high-quality materials such as nickel alloys for heat resistance.

- Implement regular inspections and component replacements to catch issues early.

- Utilize protective coatings to reduce wear and corrosion.

Enhancing Efficiency Through Optimized Maintenance and Materials

Maximizing Mixer Performance

- Choosing the right materials and maintaining a strict maintenance schedule ensures the mixer performs at its best.

- Material quality directly impacts performance, with higher-quality materials resulting in more efficient mixers and less downtime.

Innovative Technologies for Monitoring and Maintenance

- IoT Sensors: Real-time monitoring of mixer health for predictive maintenance.

- Predictive Analytics: Forecasting potential component failures before they happen.

- AI-Based Monitoring: Enhancing efficiency by optimizing the use of mixer components and identifying issues quickly.

Case Studies: Successful Durability Improvements in Resin Sand Mixers

Real-World Examples

| Foundry Name | Improvement Strategy | Result |

|---|---|---|

| Foundry A | Upgraded to nickel alloys for high-heat components | Reduced component failures by 30%. |

| Foundry B | Applied ceramic coatings on mixing blades | Increased mixer lifespan by 40%, reducing downtime. |

| Foundry C | Implemented IoT sensors for predictive maintenance | Decreased unplanned downtime by 25%. |

Key Lessons Learned

- Upgrading to durable materials, such as nickel alloys and ceramic coatings, significantly reduces maintenance needs.

- Implementing advanced technologies like IoT sensors and AI monitoring enhances predictive maintenance and reduces costly downtime.

Conclusion: Ensuring Long-Term Durability of Resin Sand Mixers

The Future of Resin Sand Mixers

- Choosing the right materials, implementing robust maintenance practices, and adopting new technologies are essential for ensuring the durability of resin sand mixers.

- Call to Action: Foundries should evaluate their mixers' current performance and material quality, upgrading where necessary to increase durability, reduce downtime, and improve overall efficiency.

By following the best practices outlined in this article, foundries can ensure that their resin sand mixers operate efficiently and last longer, ultimately driving greater productivity and cost savings.