Rust on steel structure profiles isn’t just an aesthetic issue—it can weaken your structure and increase long-term maintenance costs. If you're struggling with recurring rust and looking for a reliable solution, using a shot blasting machine can be a game-changer for efficient rust removal and surface preparation. Let's explore why shot blasting is the ideal method for removing rust and preventing future corrosion.

Shot blasting machines are highly effective for rust removal from steel structure profiles. With their high efficiency and thorough cleaning ability, shot blasting ensures that even deeply embedded rust is removed, preparing the surface for long-lasting protection.

In this article, we’ll break down the most effective rust removal techniques and explain how you can apply them to avoid long-term damage and costly downtime.

1. Why Rust is a Serious Threat to Steel Structure Profiles

Rust on steel profiles can quickly escalate from a minor inconvenience to a major safety and financial issue. If you're in industries like construction, manufacturing, or infrastructure, you know how important it is to keep your steel structures in good condition.

The key problems rust causes include:

- Weakening of the steel structure: Rust leads to structural degradation, making steel profiles more brittle and prone to failure.

- High repair costs: If left untreated, rust spreads quickly, leading to expensive repairs, surface treatments, or even the need for part replacements.

- Reduced aesthetic value: Rusty structures not only look unappealing but may also damage the reputation of your business or project.

In industries with heavy equipment, machinery, or structures exposed to harsh environments, rust can compromise safety, performance, and operational efficiency. The need for fast and effective rust removal is essential.

2. The Power of Shot Blasting Machines in Rust Removal

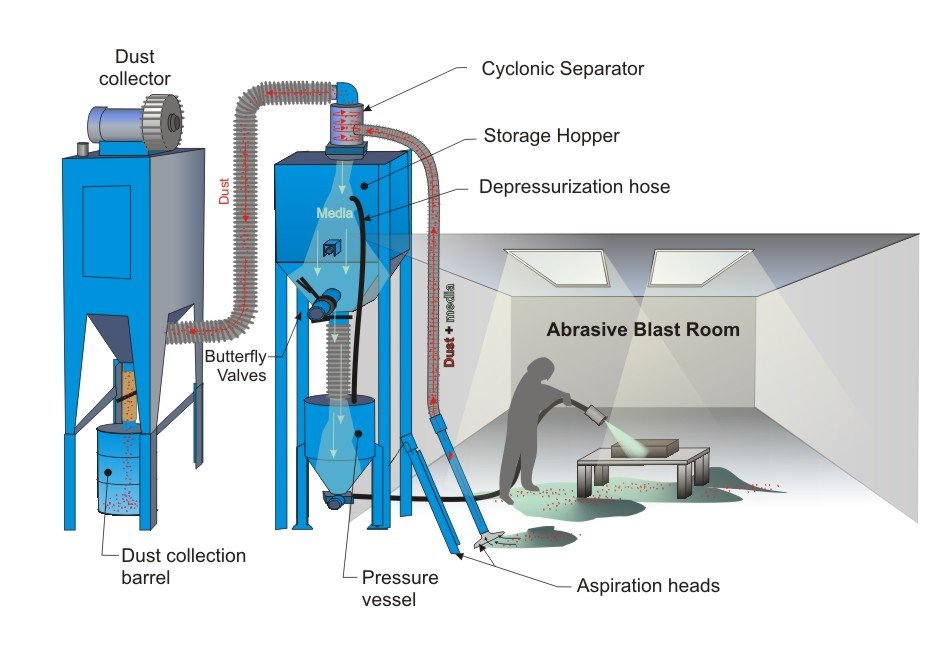

Shot blasting, a mechanical cleaning process, is one of the most efficient and reliable methods for removing rust from steel structures. A shot blasting machine propels abrasive media (such as steel shots) at high speed to clean the surface of the steel, effectively removing rust, scale, and other contaminants.

Why shot blasting is the ideal choice for rust removal:

- Complete rust removal: Shot blasting machines are capable of completely removing even the toughest rust and other contaminants, ensuring a clean and smooth surface.

- Efficiency and speed: The high-speed abrasive blasting process cleans large surfaces quickly, making it ideal for both small and large-scale projects.

- Surface preparation for coatings: Shot blasting also prepares the surface for coatings, paints, or galvanization, providing a better bond and longer-lasting protection.

How shot blasting solves your pain:

Rust removal using shot blasting machines eliminates the risk of corrosion spreading, allowing your steel profiles to maintain their structural integrity. With consistent, thorough cleaning, you can avoid costly repairs and downtime while ensuring that your steel structures are ready for protective coatings.

3. Types of Shot Blasting Machines for Rust Removal

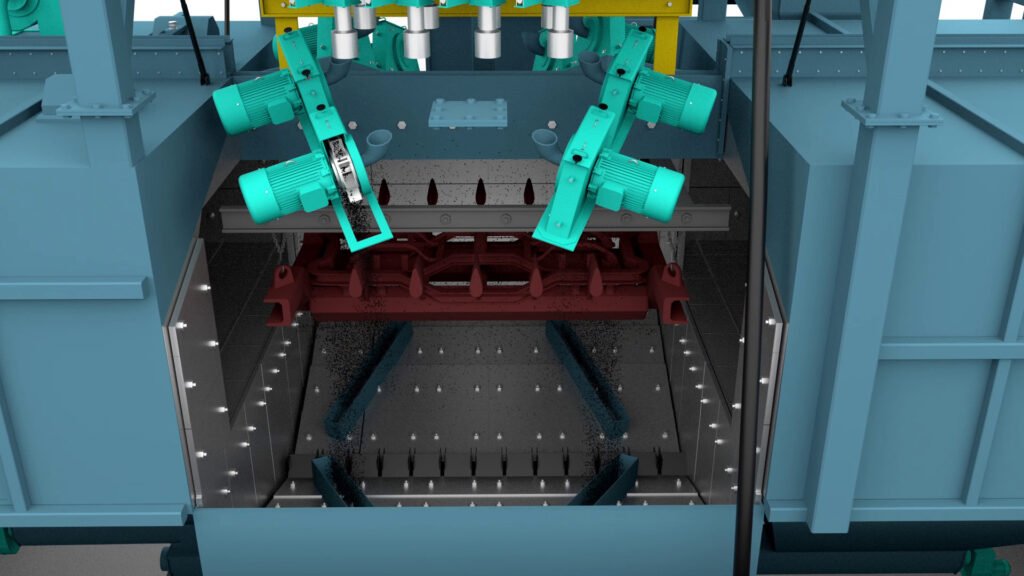

Depending on the size and type of your steel structure profiles, different types of shot blasting machines may be required. The most common options include:

1. Crawler Shot Blasting Machines:

These machines are mobile and capable of handling large steel structures. They’re ideal for rust removal on heavy, immovable steel components.

- Advantages: High mobility, efficient for large or complex steel profiles, excellent for steel beams, columns, and large sections.

2. Hanger Type Shot Blasting Machines:

These machines are often used for smaller profiles or individual parts. The steel profiles are hung inside the machine and subjected to abrasive shots from all angles.

- Advantages: Ideal for detailed and small to medium-sized profiles, effective at cleaning complex shapes.

3. Rotary Table Shot Blasting Machines:

Best for cleaning medium to large flat steel profiles. The steel profiles are placed on a rotating table, ensuring an even and thorough blast treatment.

- Advantages: Suitable for batch processing, provides uniform surface treatment.

How it addresses your pain:

Choosing the right shot blasting machine ensures maximum efficiency in rust removal for your specific needs. Whether you're dealing with large beams or intricate details, using the right equipment can reduce downtime and ensure thorough cleaning with minimal effort.

4. The Process of Using a Shot Blasting Machine for Rust Removal

The shot blasting process involves several steps that ensure the most effective removal of rust and surface preparation for further protection.

Step-by-Step Process:

- Preparation: Ensure the steel structure is placed properly within the machine, whether it's hanging, rotating, or stationary.

- Blast Cleaning: The abrasive material is blasted at high speed onto the steel surface, breaking down the rust and other contaminants.

- Inspection: After blasting, inspect the surface for any remaining rust. If needed, perform a second round of blasting or finish with manual cleaning.

- Coating (optional): Once rust is removed, apply a protective coating, paint, or galvanization to prevent future corrosion.

How it helps you:

The shot blasting process is quick, efficient, and highly effective in removing even the most stubborn rust. By ensuring a thorough cleaning and surface preparation, your steel profiles will be ready for protective treatments, reducing future maintenance costs and improving the overall longevity of your structure.

5. Preventing Rust from Returning: How Shot Blasting Helps Long-Term Protection

Removing rust is only part of the equation. Preventing future rusting is equally important for maintaining the integrity of your steel structures.

How shot blasting contributes to long-term protection:

- Surface preparation for better coating adhesion: After shot blasting, the steel surface is roughened, providing a better bonding surface for coatings, paints, or galvanization.

- Corrosion resistance: When followed by a protective coating, shot-blasted steel has a much lower chance of developing new rust, even in challenging environments like coastal or industrial areas.

- Regular maintenance: For optimal long-term results, consider periodic shot blasting as part of your ongoing maintenance routine.

How it solves your problem:

By combining shot blasting with protective coatings, you ensure your steel structures remain rust-free for years to come, avoiding recurring corrosion problems and reducing overall maintenance costs.

6. The Advantages of Professional Shot Blasting Services

While shot blasting machines can be operated in-house, professional shot blasting services offer additional benefits that ensure the job is done right, especially for larger projects or complex needs.

Why choose professional services for shot blasting?

- Expert handling: Professionals have the expertise to assess the extent of rust damage and select the best method for your specific steel profiles.

- Efficient execution: With specialized equipment, professionals can complete the job quickly, reducing downtime and improving project efficiency.

- Long-lasting results: Professionals often provide additional services like coating application, ensuring long-term rust protection.

How it addresses your pain:

Opting for professional shot blasting services means you can trust the experts to remove rust thoroughly, apply protective coatings, and provide the highest quality results, minimizing your long-term maintenance costs and ensuring your steel structures stay safe and reliable.

Conclusion:

Removing rust from steel structure profiles is crucial for maintaining the safety, durability, and appearance of your structures. Shot blasting machines offer an efficient, reliable, and thorough method for rust removal, preparing steel for protective coatings and preventing future corrosion. Whether you handle the process yourself or use professional services, shot blasting is a powerful tool for extending the lifespan of your steel assets and reducing the long-term costs of maintenance and repairs.