Reducing the import cost of a rotary table shot blasting machine requires strategic planning. Selecting the right supplier, optimizing specifications, minimizing shipping fees, and leveraging tariff exemptions can significantly cut costs. Avoid hidden fees, plan cost-effective installations, and focus on total cost of ownership rather than just the purchase price to achieve maximum savings.

Choose the Right Supplier

Selecting the right supplier is critical for cost reduction. Comparing multiple manufacturers helps assess pricing and quality variations. Direct factory purchases eliminate middlemen markups, ensuring better value for money. Additionally, verifying supplier credentials is crucial to prevent hidden costs and ensure reliability. Requesting multiple quotes and negotiating terms can lead to better deals, while a thorough background check helps avoid scams and substandard equipment.

| Factor | Importance |

|---|---|

| Direct Factory Purchase | Eliminates middlemen costs |

| Supplier Verification | Ensures reliability and quality |

| Multiple Quotes | Encourages competitive pricing |

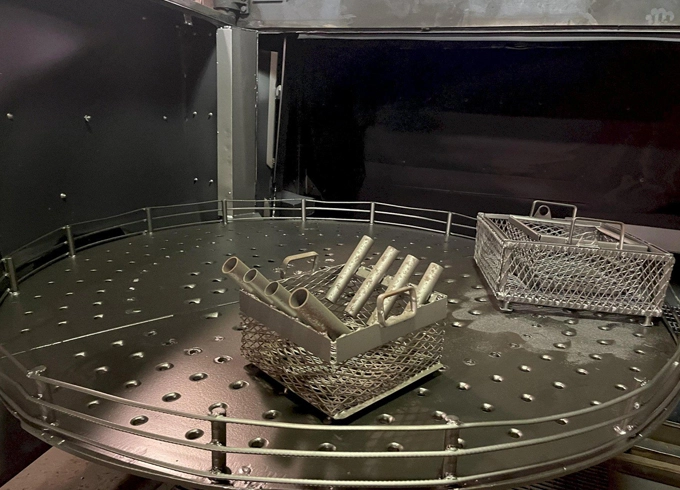

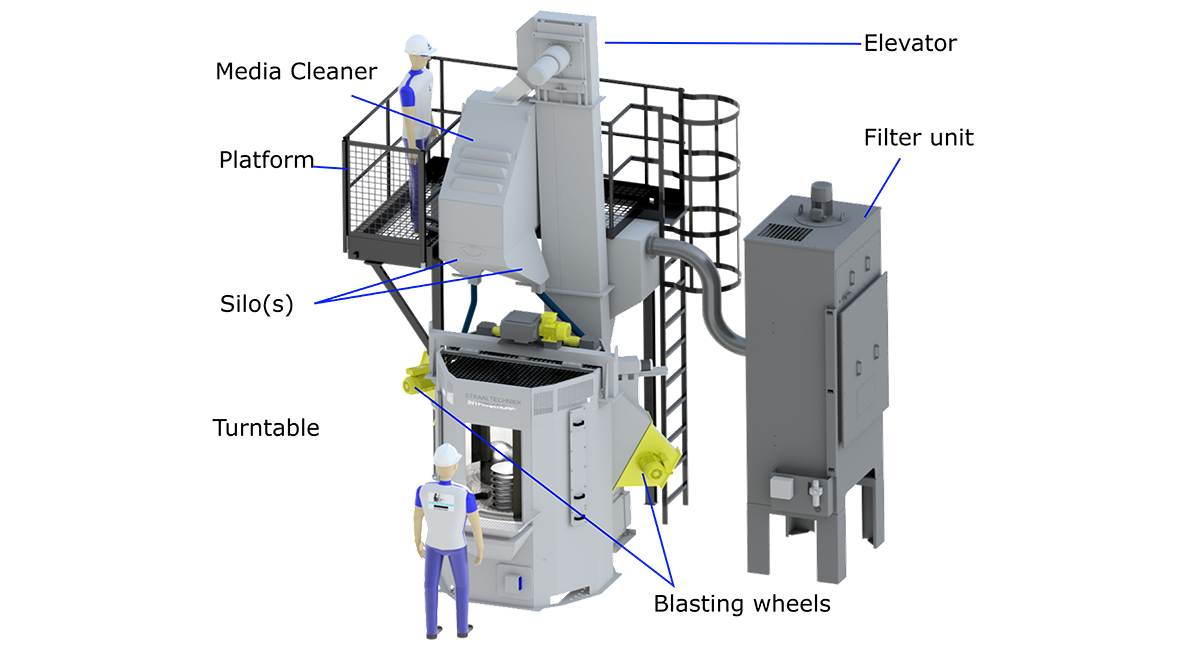

Optimize Machine Specifications

Over-specification can lead to unnecessary costs. Choosing only the essential features for your production needs prevents overspending. Modular machine designs allow for future upgrades instead of purchasing a fully loaded system upfront. Balancing automation with manual controls can also lower initial investment while maintaining efficiency. A well-optimized machine ensures that operational costs remain manageable.

Minimize Shipping Costs

Shipping costs can significantly impact the overall expense. Selecting the most cost-effective method—Less than Container Load (LCL) for small orders, Full Container Load (FCL) for bulk purchases, or breakbulk for oversized machinery—helps control costs. Disassembled shipments reduce volume and lower freight charges. Working with experienced freight forwarders secures competitive rates and prevents costly shipping mistakes.

| Shipping Method | Best For | Cost Efficiency |

|---|---|---|

| LCL | Small orders | Moderate |

| FCL | Bulk shipments | High |

| Breakbulk | Oversized machinery | Variable |

Reduce Import Duties and Taxes

Understanding international trade regulations can save significant costs. Checking for tariff exemptions under free trade agreements reduces duty costs. Declaring the correct HS code ensures accurate duty calculations, avoiding excessive fees. Utilizing bonded warehousing can delay duty payments, improving cash flow. Companies should also familiarize themselves with local tax regulations to further optimize import expenses.

Avoid Hidden Fees and Extra Charges

Unexpected costs can quickly inflate the overall expense. Reviewing Incoterms (EXW, FOB, CIF, DDP) clarifies cost responsibilities and prevents surprise expenses. Confirming packaging fees, export clearance costs, and documentation charges upfront eliminates hidden fees. Negotiating with suppliers for all-inclusive pricing on essential services, such as customs clearance and insurance, helps avoid additional charges.

Plan for Cost-Efficient Installation and Setup

Installation costs can be minimized by training in-house technicians instead of relying on expensive overseas engineers. Remote installation guidance from the manufacturer further cuts travel expenses. Choosing standard components over custom parts ensures easier maintenance and lower service costs. Proper planning prevents downtime and unexpected labor charges, improving overall efficiency.

Invest in Long-Term Cost Savings

Reducing import costs isn’t just about the initial purchase—it’s about long-term savings. Selecting energy-efficient machines lowers operational expenses. Ensuring spare parts availability prevents costly downtime and emergency imports. Evaluating the total cost of ownership (TCO), including maintenance, power consumption, and lifecycle costs, provides a clearer financial outlook.

Work with a Trusted Import Partner

Hiring experienced customs brokers prevents compliance issues and costly delays. Partnering with logistics firms specializing in industrial machinery imports streamlines the process and minimizes unexpected fees. Regularly auditing the supply chain identifies further cost-saving opportunities, ensuring continuous improvements in import efficiency.

Final Thoughts

Cutting import costs requires a comprehensive approach, from supplier selection to installation. Businesses should prioritize total cost savings rather than just focusing on the lowest purchase price. Consulting with import specialists and carefully planning each stage of the import process will ensure smooth operations and maximum cost efficiency.