Are you tired of production inefficiencies, resin waste, or frequent downtime in your casting line?

To choose the right single arm resin sand mixer, match your production capacity with the appropriate machine size by evaluating daily sand use, process type, and space constraints.

Choosing the wrong mixer leads to inconsistent sand quality, excessive maintenance, and ultimately—profit loss. In this guide, I’ll walk you through how to size your mixer accurately for your operations and avoid common mistakes I’ve seen in my 20+ years in the industry.

Why Choosing the Right Sand Mixer Matters?

Production bottlenecks? Sand quality inconsistencies? Maintenance nightmares? These often start with the wrong mixer choice.

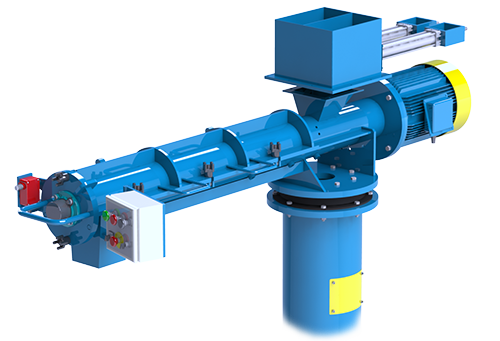

A single arm resin sand mixer ensures optimal mixing quality and efficiency—if matched correctly to your line’s output and layout.

A mismatch in mixer capacity and production demand causes major issues—under-mixing, overuse of resin, or delayed mold preparation. I’ve seen factories lose hours of productive time daily just from misaligned equipment. Understanding your capacity is the first step to solving this.

Understanding Your Production Line Capacity?

Don’t guess your output—quantify it. “Capacity” means how much sand your line uses per hour, influenced by mold size, casting frequency, and shift schedules.

To choose the right mixer, calculate your actual resin sand usage per hour, accounting for batch cycles and shift durations.

Let’s break it down with a simple table:

| Daily Casting Volume (tons) | Operating Hours | Required Mixer Output (tons/hour) |

|---|---|---|

| 5 tons/day | 8 hours | 0.6 – 1.0 |

| 20 tons/day | 8 hours | 2.5 – 3.5 |

| 50 tons/day | 16 hours | 3.5 – 5.0 |

Key influencing factors:

- Molding method: Manual or automatic?

- Batch cycle: Continuous casting vs small runs?

- Maintenance schedule: Do you account for downtime?

It’s essential to avoid sizing your machine just for “average use”. Always include your peak demand in the calculation.

What Types of Resin Sand Mixers Exist—and Why Choose a Single Arm?

Batch or continuous? Single arm or double arm? There are several types, but not all fit your operations.

A single arm mixer is ideal for compact layouts, lower resin use, and flexible batch cycles—perfect for small to mid-sized foundries.

Here’s a quick comparison:

| Mixer Type | Best For | Pros | Cons |

|---|---|---|---|

| Single Arm | 1–20 tons/hour lines | Compact, easy clean-up, economical | Not ideal for very large output |

| Double Arm | 20–60+ tons/hour lines | High-speed, balanced mixing | Bigger footprint, higher cost |

| Continuous Mixer | Automated large-scale plants | Constant output, integrated control | High setup and maintenance cost |

I often recommend single arm mixers to clients with:

- Limited floor space

- Multiple short casting runs per day

- Strict resin control requirements

They’re more than enough for 90% of casting plants I’ve worked with.

What Key Features Should You Consider?

All mixers are not created equal—even single arm mixers vary widely.

Prioritize mixing uniformity, ease of cleaning, energy use, and integration capabilities when selecting your mixer.

Features I always advise clients to evaluate:

| Feature | Ideal Specification |

|---|---|

| Capacity Range | 1–20 tons/hour |

| Mixing Cycle Time | < 2 minutes |

| Cleaning Access | Tool-free removable arms |

| Power Consumption | < 30 kW (for mid-size models) |

| Automation Compatibility | PLC-ready, IoT integration supported |

| Maintenance Cycle | Less than 30 minutes per shift |

From experience, ease of cleaning is often underestimated. A 10-minute cleaning time vs 45 minutes can save you hundreds of hours yearly.

Also, don’t overlook resin compatibility—check the type (furan, phenolic) your foundry uses and whether the mixer accommodates it efficiently.

How to Match Mixer Size to Production Output: A Step-by-Step Guide

Still unsure where to start? Let’s go step by step.

Use this 5-step sizing formula to confidently match your mixer with your actual production demand.

Step-by-Step Guide:

- Measure Daily Sand Usage: Total tons of resin sand needed per day.

- Calculate Operating Hours: Divide sand usage by total shift hours.

- Account for Downtime: Deduct 10–15% for maintenance.

- Add Growth Buffer: Add 10–20% for future expansion.

- Select Model: Compare final number to machine specs.

Common Mistakes to Avoid

I've audited many factories and seen the same issues repeat.

Oversized or undersized mixers create downtime, energy waste, and maintenance chaos. Avoid these pitfalls by planning properly.

Common Pitfalls:

| Mistake | Consequence |

|---|---|

| Oversizing | Energy waste, unnecessary cost, wasted floor space |

| Undersizing | Bottlenecks, overheating, mixer wear |

| Ignoring Maintenance Access | Delayed clean-ups, lost production time |

| No Automation Consideration | Higher labor cost, error-prone dosing |

| Resin Type Mismatch | Poor bonding, casting defects |

When I visit client sites, I always double-check the actual resin-to-sand ratio they use.

This often differs from their assumption and can change the entire machine requirement.

Use Case Scenarios by Industry

Here’s how real-world clients matched their mixer to their needs.

Smaller foundries need nimble mixers. Large-scale operations may need to look beyond single arm designs.

Industry Scenarios Table

| Industry | Daily Sand Use | Recommended Mixer Type |

|---|---|---|

| Small Foundry Shop | 5 tons/day | 1.5–2 ton/hour single arm |

| Auto Parts Plant | 20 tons/day | 3–4 ton/hour single arm |

| Large Casting Facility | 50+ tons/day | Double arm or continuous mixer |

From my experience, the auto parts industry benefits the most from right-sized single arm mixers—they combine precision and speed with manageable resin usage.

Conclusion

Choosing the right single arm resin sand mixer is about precision matching, not over-investing.

Proper sizing leads to higher productivity, less waste, and future-proofing.

[Bonus] Checklist: What to Ask Your Mixer Supplier

Before you buy, arm yourself with these questions.

| Question | Why It Matters |

|---|---|

| Is it compatible with our resin type? | Avoids bonding issues |

| Can it integrate with our automation system? | Future scalability |

| How easy is cleaning and arm replacement? | Maintenance efficiency |

| What's the power draw and cycle time? | Cost-effectiveness |

| Are spare parts and service readily available? | Downtime prevention |

Call-to-Action

Still unsure which mixer suits your production line?

👉 Contact Hitech-China for a free consultation and sizing analysis tailored to your specific needs.

Let’s make your sand mixing process smarter, faster, and more profitable.