Selecting the wrong supplier for a rotary table shot blasting machine can lead to frequent breakdowns, high maintenance costs, and inefficient surface treatment. Avoid costly mistakes by choosing the right supplier.

The best rotary table shot blasting machine suppliers offer high-quality, durable equipment, customizable options, competitive pricing, reliable after-sales support, and compliance with industry standards. Following a structured procurement checklist can help you find the most suitable supplier.

With so many options available, how do you ensure you’re making the right choice? Let’s break it down step by step.

Assess Supplier Experience and Reputation

Manufacturers with a strong track record are more likely to deliver high-quality products and reliable services.

A reputable supplier should have at least 10+ years of experience in shot blasting technology, positive customer reviews, and recognized industry certifications such as ISO and CE.

Evaluating Supplier Credibility

- Research the company’s background, history, and key milestones.

- Read customer testimonials and case studies to assess performance.

- Check if they have supplied machines to reputable companies in your industry.

- Verify certifications for quality and safety standards.

| Key Criteria | Why It Matters |

|---|---|

| Years in business | Indicates expertise and industry knowledge |

| Customer reviews | Reveals real-world machine performance |

| Industry certifications | Ensures compliance with quality and safety standards |

| Case studies | Demonstrates proven success in similar applications |

Evaluate Product Quality and Customization Options

Not all rotary table shot blasting machines are created equal. You need a machine that matches your specific production needs.

A good supplier offers high-quality materials, durable components, and customization options to meet your exact requirements.

What to Look for in Product Quality

- Material durability: Check the build quality and materials used in key components.

- Blast wheels and chamber lining: These directly impact machine performance and lifespan.

- Customization options: Can the supplier modify the machine based on your workload and material type?

- Performance testing: Request a demo or sample test to see the machine in action.

Compare Pricing and Total Cost of Ownership

Price alone should not be the deciding factor. Hidden costs and long-term operational expenses can make a cheaper option more expensive in the long run.

Look beyond the initial price tag and consider maintenance, spare parts, and energy consumption when evaluating the total cost of ownership.

Cost Considerations

- Request a detailed quotation that includes base price, optional features, and additional costs.

- Compare energy efficiency to minimize long-term expenses.

- Check spare parts availability to avoid production delays.

- Beware of unusually low prices—these may indicate substandard materials.

Review After-Sales Support and Warranty Policies

A supplier’s job doesn’t end after the sale. Reliable after-sales support ensures smooth operation and minimal downtime.

Choose a supplier with comprehensive warranty terms, responsive technical support, and easy access to spare parts.

After-Sales Considerations

- Warranty coverage: Check for parts, labor, and service coverage.

- Technical support: Is it available on-site, remotely, or both?

- Response time: How quickly can issues be resolved?

- Spare parts availability: Can replacements be sourced easily?

Analyze Supplier’s Production and Delivery Capabilities

A supplier’s production capacity and delivery reliability directly impact your project timeline.

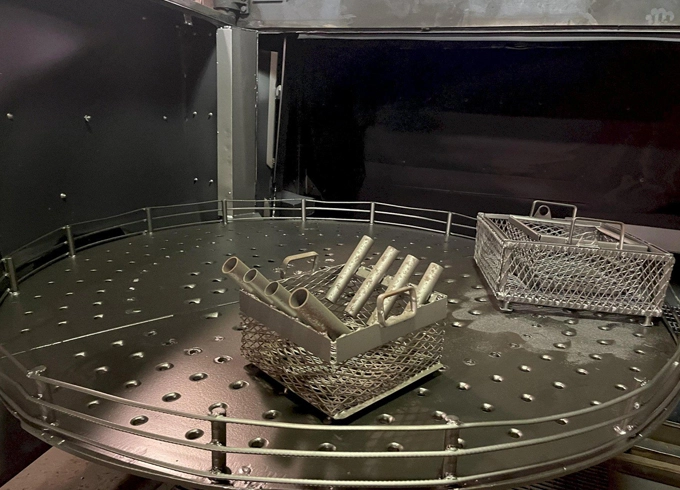

Visit the factory or request a virtual tour to verify production capabilities and quality control measures.

Key Factors to Assess

- Lead times: How long does it take to deliver standard and custom orders?

- Packaging and shipping: Are machines well-protected during transit?

- Production scalability: Can the supplier handle bulk orders if needed?

Verify Compliance with Safety and Industry Standards

Safety and compliance should never be overlooked.

Ensure the supplier meets international safety regulations (CE, ANSI) and provides necessary documentation.

Compliance Checklist

- Certifications: CE, ISO, ANSI, or relevant local industry standards.

- User manuals: Detailed operation and maintenance guidelines.

- Environmental impact: Dust control measures and energy efficiency.

Check Payment Terms and Contract Transparency

Clear and fair payment terms protect both buyer and supplier.

Negotiate flexible payment options and ensure all contract details are transparent.

Important Contractual Terms

- Payment flexibility: Installment plans, LC terms, or milestone-based payments.

- Warranty and service agreements: Clearly defined terms.

- Refund policies: What happens in case of defects or delays?

- Legal protections: Ensure clarity in dispute resolution terms.

Procurement Checklist for Selecting a Supplier

✔️ Experience and reputation in the industry

✔️ High-quality materials and machine durability

✔️ Customization options for specific applications

✔️ Competitive pricing with transparent cost breakdown

✔️ Strong after-sales support and readily available spare parts

✔️ Reliable production capacity and delivery timelines

✔️ Compliance with industry and safety standards

✔️ Fair and clear payment terms with legal protection

Conclusion

Choosing the right rotary table shot blasting machine supplier is crucial for ensuring long-term reliability, efficiency, and cost-effectiveness. By following this structured procurement checklist, you can evaluate potential suppliers and make an informed decision. Contact industry experts for additional guidance to find the best supplier for your needs.