Are you overwhelmed by the sheer variety of conveyor shot blasting machines available? Choosing the right one is critical to meeting your industrial needs effectively and efficiently.

The best conveyor shot blasting machine aligns with your specific requirements, including workpiece material, production goals, surface treatment demands, and abrasive media compatibility.

Keep reading to learn how to select the perfect machine for your industrial applications.

What Are Conveyor Shot Blasting Machines?

Understanding the basics of conveyor shot blasting machines is the first step toward making an informed choice.

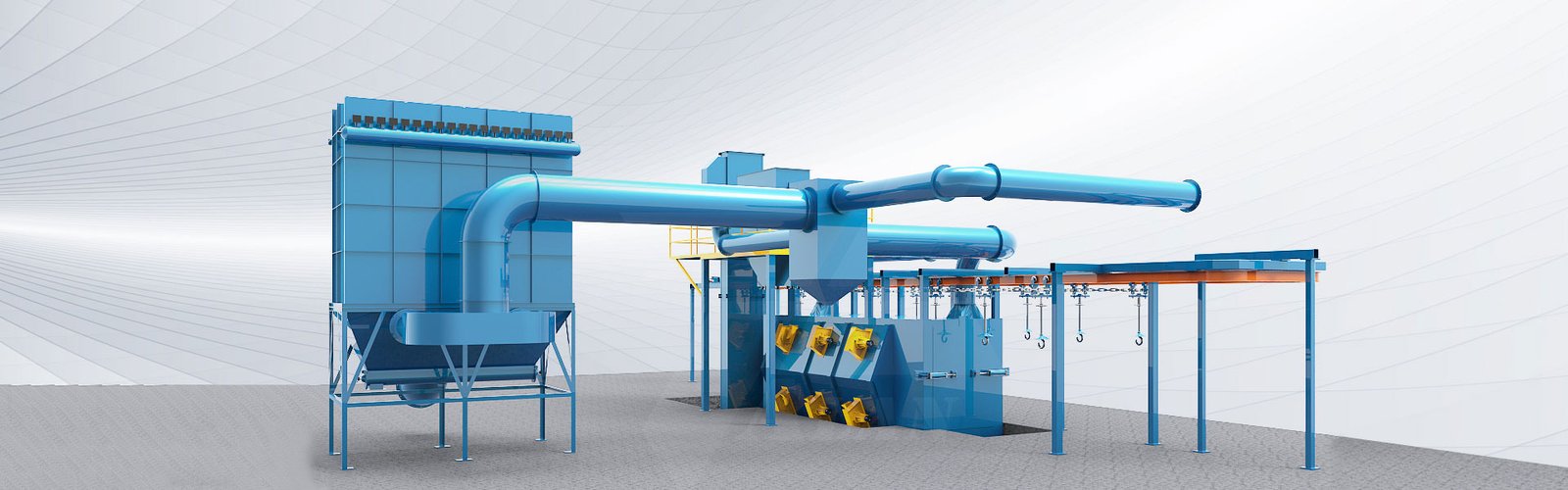

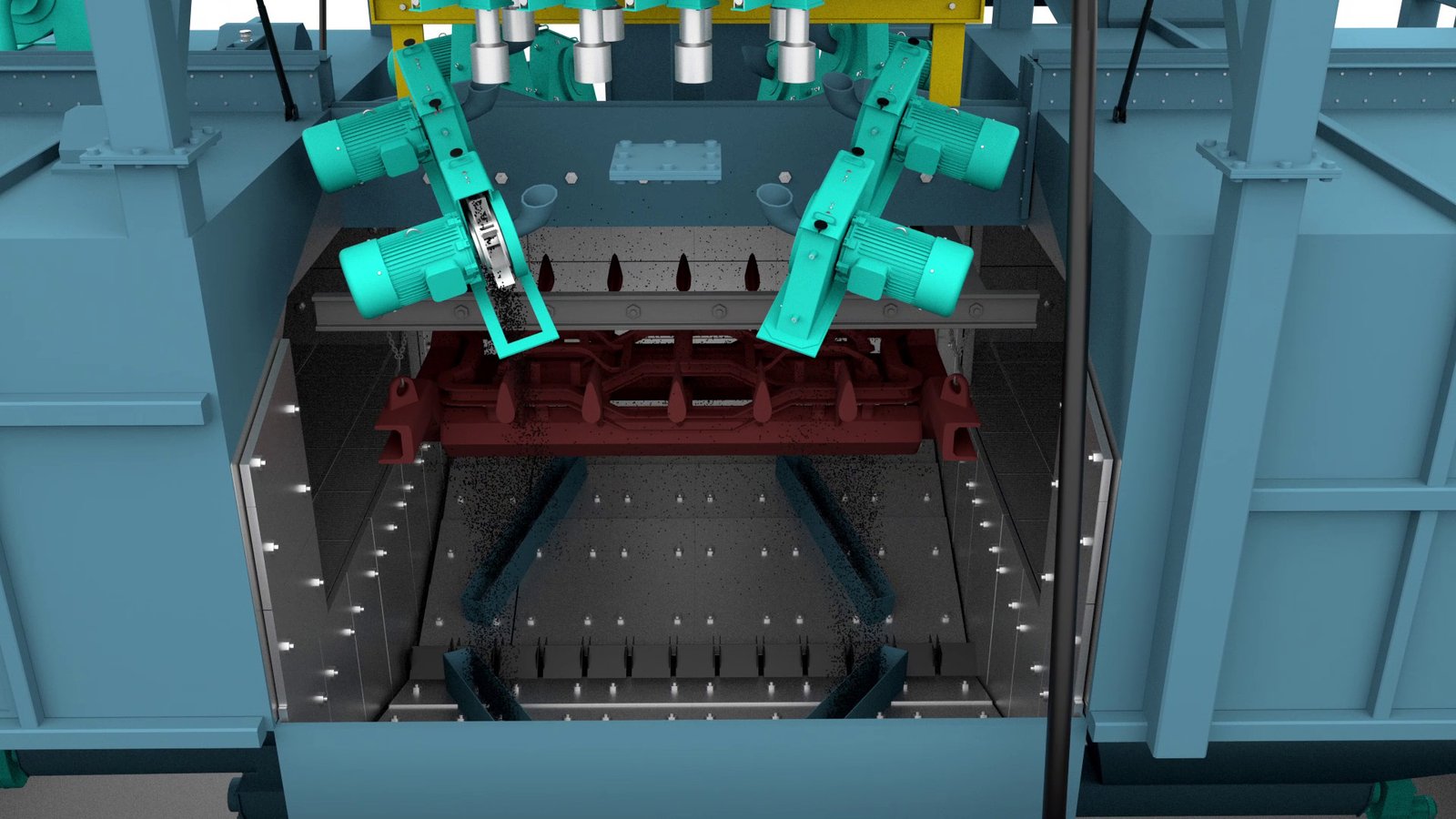

Conveyor shot blasting machines are surface preparation tools designed to clean, strengthen, or polish workpieces using abrasive materials propelled at high speeds. They utilize a conveyor system to move parts through a blasting chamber, where they are treated uniformly.

The conveyor system ensures consistent material flow, while the blasting chamber houses turbines or nozzles that propel abrasive media at the target surface. This process is essential for applications such as rust removal, paint stripping, and surface strengthening.

Dive Deeper: Why They’re Indispensable in Modern Industry

Conveyor shot blasting machines are a cornerstone of surface treatment processes in industries like automotive, construction, and aerospace. Their efficiency lies in their ability to process parts continuously, ensuring uniform results with minimal manual intervention. As industries demand faster production and higher-quality finishes, these machines have become critical for achieving these goals.

Key Factors to Consider When Choosing a Conveyor Shot Blasting Machine

2.1 Workpiece Material and Size

Struggling to match a machine to your workpieces? Start with material and size considerations.

The machine you choose must be compatible with your workpiece's material type—whether metal, plastic, or wood—and its dimensions, weight, and shape.

Dive Deeper: Matching Machine Design to Workpiece Characteristics

Materials like steel or aluminum demand robust systems that can handle their density, while delicate materials like plastic require gentler blasting settings. Similarly, the machine's dimensions should accommodate the size and complexity of your parts. For example, intricate automotive components require precise blasting to reach every corner without causing damage.

By considering these factors, you ensure that the machine delivers optimal surface treatment without compromising on quality or efficiency.

2.2 Throughput and Production Efficiency

How do you balance productivity with quality in your operations? Throughput is key.

Evaluate your production volume, conveyor speed, and the machine’s capacity to handle continuous operations. Choose a system that aligns with your throughput goals.

Dive Deeper: Maximizing Operational Efficiency

Production efficiency hinges on factors like conveyor speed and blast zone size. High-speed conveyors with wide blast zones process more parts in less time. However, balancing speed with precision is crucial—overlooking this can result in uneven or incomplete surface preparation. Modern machines equipped with automation features further enhance throughput by minimizing downtime and ensuring consistency.

2.3 Surface Preparation Requirements

Does your application demand rust removal, paint stripping, or shot peening? Tailor your choice to these needs.

Match the machine's blasting intensity and coverage to your specific surface treatment requirements for optimal results.

Dive Deeper: Aligning Machine Features with Treatment Goals

Surface preparation requirements vary widely across industries. For instance, shot peening in aerospace manufacturing requires precision to enhance fatigue strength, while rust removal for construction materials demands high-impact blasting. Selecting a machine with adjustable settings and diverse media options ensures it meets both current and future needs.

2.4 Abrasive Media Compatibility and Dust Collection

Is abrasive media compatibility limiting your options? Here’s what you need to know.

Your chosen machine must support the right abrasive media—whether steel shot, grit, or glass beads—and feature an efficient dust collection system.

Dive Deeper: Reducing Downtime and Improving Work Conditions

The abrasive media you use determines surface finish quality and machine wear. Steel shot offers aggressive cleaning, while glass beads deliver a smoother finish. A robust dust collection system ensures a clean work environment, reduces health risks, and complies with safety standards. Investing in these features saves time and maintenance costs in the long run.

Benefits of Using Conveyor Shot Blasting Machines

Conveyor shot blasting machines provide faster, more uniform cleaning, improve productivity, and enhance worker safety with enclosed systems.

Dive Deeper: Unlocking Long-Term Value

By automating surface preparation, these machines significantly reduce manual effort and operational downtime. They also extend the lifespan of treated components by removing impurities and creating durable finishes. The safety advantages of enclosed blasting systems, which minimize operator exposure to dust and debris, make them a must-have for modern facilities.

Common Types of Conveyor Shot Blasting Machines

Spinner Hanger Systems

Best for large, complex workpieces requiring controlled blasting.

Tumble Blast Machines

Ideal for smaller, bulkier parts processed in batches.

Roller Conveyor Machines

Designed for long, flat components and continuous production lines.

Comparison Table

| Machine Type | Key Feature | Best For |

|---|---|---|

| Spinner Hanger | Suspends workpieces | Large, intricate parts |

| Tumble Blast | Rotating drum design | Small, bulk components |

| Roller Conveyor | Flat conveyor belt | Sheets, beams, and pipes |

Expert Tips for Selecting the Best Conveyor Shot Blasting Machine

Struggling to decide? Here are some practical tips:

- Consult manufacturers for custom configurations.

- Evaluate long-term costs, including energy and maintenance.

- Prioritize machines with advanced automation for better efficiency.

Dive Deeper: Why Expertise Matters

Custom configurations tailored to your industry save money and increase machine longevity. Investing in automation minimizes human error and ensures consistent quality, which is vital for maintaining customer trust and reducing returns. Partnering with reputable manufacturers simplifies decision-making and provides ongoing support for your machine.

Conclusion: Make an Informed Investment

Selecting the right conveyor shot blasting machine involves evaluating workpiece material, throughput, surface preparation needs, and abrasive media compatibility. Matching these factors to your operational goals ensures maximum productivity and quality. For expert advice and custom solutions, feel free to contact us today!