Selecting the wrong conveyor shot blasting machine1 can lead to inefficiency, excessive operational costs, and inadequate surface treatment. Many manufacturers struggle with choosing the right model, often ending up with machines that don't match their production requirements.

To choose the right conveyor shot blasting machine1, businesses must evaluate machine types, key performance parameters2, and industry-specific needs. This guide will help you make an informed decision by comparing different models and their specifications.

If you’re unsure which shot blasting machine suits your business, this guide will clarify all critical factors, from conveyor speed to material compatibility.

What Are the Different Types of Conveyor Shot Blasting Machines?

Shot blasting needs vary by industry. Some businesses require aggressive cleaning for heavy-duty steel plates, while others need gentle processing for fragile aluminum parts. Choosing the wrong type can result in material damage, production bottlenecks, or high operational costs.

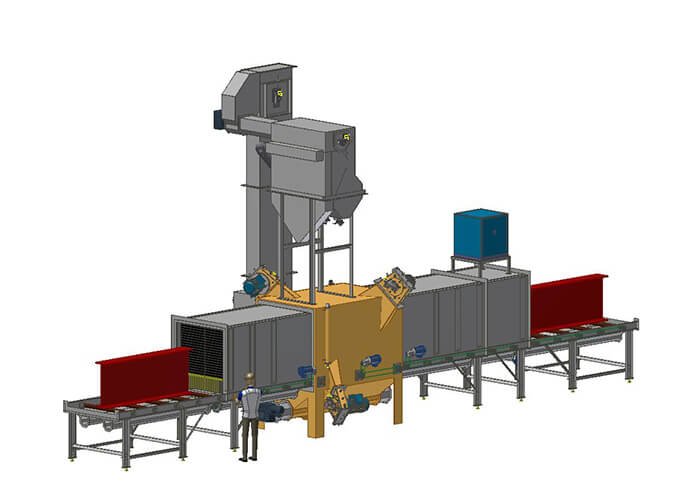

There are multiple types of conveyor shot blasting machine1s, each designed for specific applications. Selecting the correct model ensures efficiency and surface treatment quality.

Comparison of Different Conveyor Shot Blasting Machines

| Machine Type | Best For | Key Features |

|---|---|---|

| Roller Conveyor Shot Blasting Machine | Steel plates, I-beams, profiles | High-speed processing, continuous cleaning, ideal for construction and shipbuilding |

| Mesh Belt Shot Blasting Machine | Aluminum castings, automotive parts | Uniform cleaning, minimizes material distortion, suitable for delicate components |

| Overhead Conveyor Shot Blasting Machine | Complex shapes, large castings | 360-degree coverage, customizable for large-scale production |

| Wire Mesh Belt Shot Blasting Machine | Small or thin components | Even blasting, effective for high-volume production |

Selecting the right type depends on your production volume, material properties, and surface quality requirements.

What Key Performance Factors Should You Consider?

Investing in a conveyor shot blasting machine1 without considering technical parameters can lead to excessive abrasive consumption, poor cleaning efficiency, or unnecessary wear and tear.

Key performance indicators such as conveyor speed, blasting intensity, and dust collection efficiency determine the suitability of a machine for your operations.

Critical Parameters for Selection

| Parameter | Importance | Recommended Range |

|---|---|---|

| Conveyor Speed | Affects throughput and cycle time | 0.5–3 m/min (adjustable) |

| Blasting Power | Determines the intensity of cleaning | 11–75 kW per turbine |

| Abrasive Media | Different abrasives impact surface finish | Steel shot, grit, or aluminum oxide |

| Dust Collection System | Essential for workplace safety and compliance | 95–99% dust removal efficiency |

| Workpiece Size Compatibility | Ensures machine can handle your components | Customizable per industry needs |

Failing to optimize these parameters can result in inefficient cleaning, excessive energy use, and unnecessary downtime.

How Do You Balance Cost and Performance?

Many businesses focus on upfront machine costs without considering operational expenses, leading to unexpected maintenance and higher running costs.

The best investment balances initial cost, performance, and long-term return on investment (ROI). Understanding operational expenses helps in decision-making.

Cost Breakdown and ROI Analysis

| Cost Factor | Initial Investment | Ongoing Costs | ROI Impact |

|---|---|---|---|

| Machine Price | $50,000–$500,000 | - | Determines upfront budget |

| Abrasive Consumption | - | $0.10–$1 per kg | Directly affects operational expenses |

| Maintenance & Spare Parts | - | Varies by usage | Affects downtime and productivity |

| Energy Consumption | - | 10–100 kW per hour | Impacts overall operating costs |

A well-chosen machine not only lowers operational costs but also increases production efficiency, improving long-term profitability.

Industry-Specific Recommendations

Choosing the right shot blasting machine requires a clear understanding of your industry’s needs. Different sectors require different levels of cleaning intensity, surface finish precision, and material handling.

Best Conveyor Shot Blasting Machines by Industry

| Industry | Recommended Machine | Benefits |

|---|---|---|

| Automotive | Mesh Belt or Wire Mesh Belt | Precise cleaning, minimal material stress |

| Construction | Roller Conveyor | High-speed cleaning for large steel profiles |

| Aerospace | Overhead Conveyor | 360-degree coverage, delicate treatment |

| Foundry & Metalworking | Wire Mesh Belt | Efficient cleaning of small cast parts |

Choosing an industry-specific machine ensures efficiency, cost-effectiveness, and superior surface preparation.

Conclusion

Selecting the right conveyor shot blasting machine1 requires evaluating machine types, key performance parameters2, and cost-effectiveness. By understanding your production requirements and matching them to the right system, you can optimize efficiency, reduce costs, and ensure high-quality surface treatment.