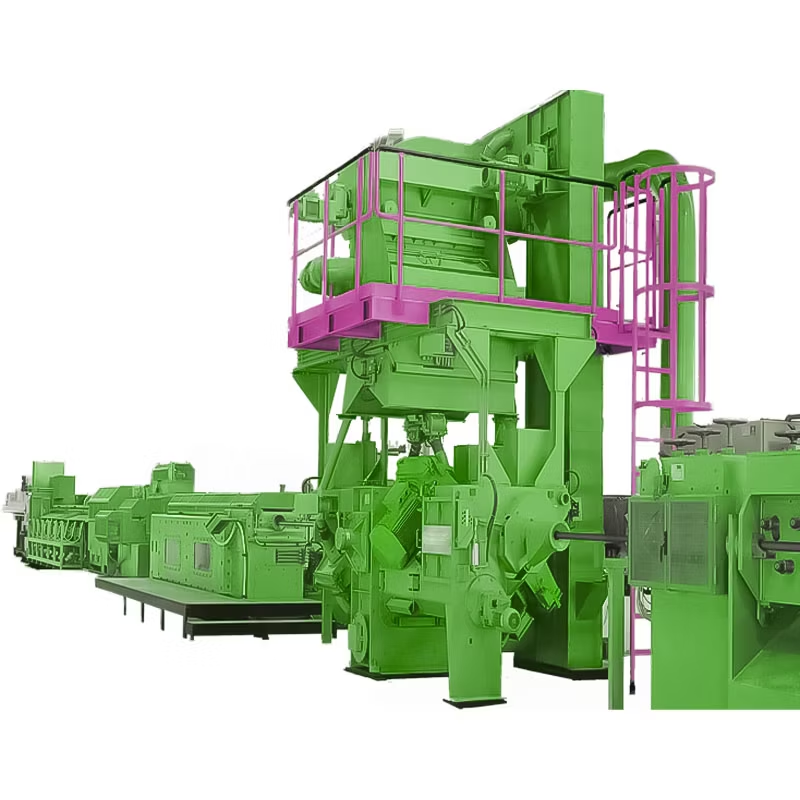

Many industries face inconsistent surface treatment results due to inefficient shot blasting processes. Poor efficiency leads to higher operational costs and reduced productivity.

The efficiency of wire rod shot blasting machines depends on several factors, including abrasive quality1, turbine performance2, machine settings3, maintenance schedules, and environmental conditions. Optimizing these elements ensures higher productivity and consistent surface treatment results.

Understanding these key factors helps industrial users enhance their shot blasting operations, minimize costs, and achieve optimal surface cleaning performance.

How Does Abrasive Quality Impact Shot Blasting Efficiency?

Using low-quality or contaminated abrasives can result in uneven surface finishes and increased wear on machine components.

High-quality abrasives improve cleaning efficiency, reduce machine wear, and provide uniform surface treatment. Choosing the right abrasive type, size, and hardness is crucial for maximizing shot blasting performance.

Key Considerations for Abrasive Quality

| Factor | Impact on Efficiency |

|---|---|

| Abrasive Size | Smaller abrasives clean finer details but may not remove heavy contaminants effectively. |

| Hardness | Harder abrasives increase impact force but can wear out machine components faster. |

| Shape | Round abrasives provide smoother finishes, while angular abrasives improve rust and scale removal. |

| Contamination | Dirty or reused abrasives decrease cleaning efficiency and cause machine blockages. |

Regularly monitoring and replacing worn abrasives ensures consistent shot blasting performance.

How Does Turbine Performance Affect Blasting Efficiency?

A poorly maintained turbine reduces blasting power, leading to uneven surface treatment and extended processing times.

Turbine efficiency directly affects abrasive velocity and distribution. Proper maintenance, balanced blades, and correct control cage positioning improve blasting performance.

Ways to Optimize Turbine Performance

- Ensure Proper Alignment: Misaligned turbines cause uneven abrasive distribution.

- Check Blade Wear: Replace blades when they are half-worn to maintain performance.

- Optimize Control Cage Positioning: Adjusting the control cage ensures abrasives hit the workpiece at the correct angle.

- Regularly Inspect Bearings and Seals: Worn bearings reduce turbine speed and blasting effectiveness.

By maintaining turbine components, industries can ensure maximum energy transfer to abrasives for efficient cleaning.

How Do Machine Settings Influence Performance?

Incorrect settings can lead to inefficient blasting, excessive abrasive consumption, and poor surface cleaning results.

Optimizing machine settings3, including abrasive flow rate, turbine speed, and conveyor speed, ensures effective and efficient shot blasting.

Key Machine Settings to Optimize

| Setting | Effect on Efficiency |

|---|---|

| Abrasive Flow Rate | Too much abrasive causes wastage; too little reduces cleaning effectiveness. |

| Turbine Speed | Higher speeds increase impact force but can lead to excessive wear. |

| Conveyor Speed | A slow conveyor results in over-blasting, while a fast conveyor may lead to incomplete cleaning. |

| Airflow in Dust Collector | Proper airflow prevents dust accumulation, improving visibility and blasting performance. |

Proper calibration of these settings optimizes efficiency and extends the lifespan of machine components.

Why Is Regular Maintenance Critical for Efficiency?

Neglecting maintenance leads to machine failures, increased energy consumption, and decreased blasting quality.

Regular inspections and preventive maintenance ensure that all components function efficiently, reducing downtime and repair costs.

Essential Maintenance Tasks

| Frequency | Maintenance Task |

|---|---|

| Daily | Check turbines, inspect abrasive flow, and clean dust filters. |

| Weekly | Lubricate bearings, adjust control cages, and inspect conveyor belts. |

| Monthly | Replace worn blades, check alignment, and adjust motor settings. |

| Quarterly | Inspect electrical connections and replace heavily worn parts. |

A proactive maintenance schedule prevents costly failures and ensures continuous high efficiency.

How Do Environmental Conditions Affect Blasting Efficiency?

Humidity, temperature, and workplace cleanliness can impact the performance of shot blasting machines.

Controlling environmental conditions, such as maintaining optimal humidity levels and minimizing dust accumulation, improves shot blasting efficiency.

Environmental Factors to Consider

- Humidity: High moisture levels cause abrasives to clump, reducing cleaning effectiveness.

- Temperature: Extreme temperatures affect machine performance and operator safety.

- Workplace Cleanliness: Dust accumulation can clog filters and reduce visibility, lowering efficiency.

- Ventilation: Proper airflow prevents heat buildup and improves abrasive recovery.

Maintaining a controlled environment ensures consistent and high-quality blasting results.

Conclusion

The efficiency of wire rod shot blasting machines depends on multiple factors, including abrasive quality1, turbine performance2, machine settings3, maintenance, and environmental conditions. By optimizing these elements, industries can achieve consistent surface treatment results, reduce operational costs, and maximize machine lifespan.

Understanding abrasive quality is crucial for improving cleaning efficiency and reducing machine wear. Explore this link to learn more. ↩ ↩

Turbine performance directly affects blasting power and efficiency. Discover how to optimize it for better results. ↩ ↩

Optimizing machine settings is key to effective blasting. Learn how to calibrate them for maximum efficiency. ↩ ↩ ↩