Shot Blasting Machine: Efficient Cleaning?

Struggling with inconsistent surface quality, poor paint adhesion, or time-consuming cleaning processes? These are common pain points I’ve seen across various industries. Fortunately, there’s a more effective solution. A shot blasting machine uses high-speed steel shot or grit propelled by a turbine to clean, strengthen, and prepare metal surfaces. Compared to sandblasting or acid pickling, […]

Case Study: Upgrading to a Resin Sand Mixing Line

Back when we were running traditional green sand lines in some of our partner foundries across West Africa, quality issues were a constant battle. Inconsistent molds, high scrap rates, dusty work environments—it all added up. We knew we needed a smarter solution. Upgrading to a resin sand mixing line transformed not just the casting quality, […]

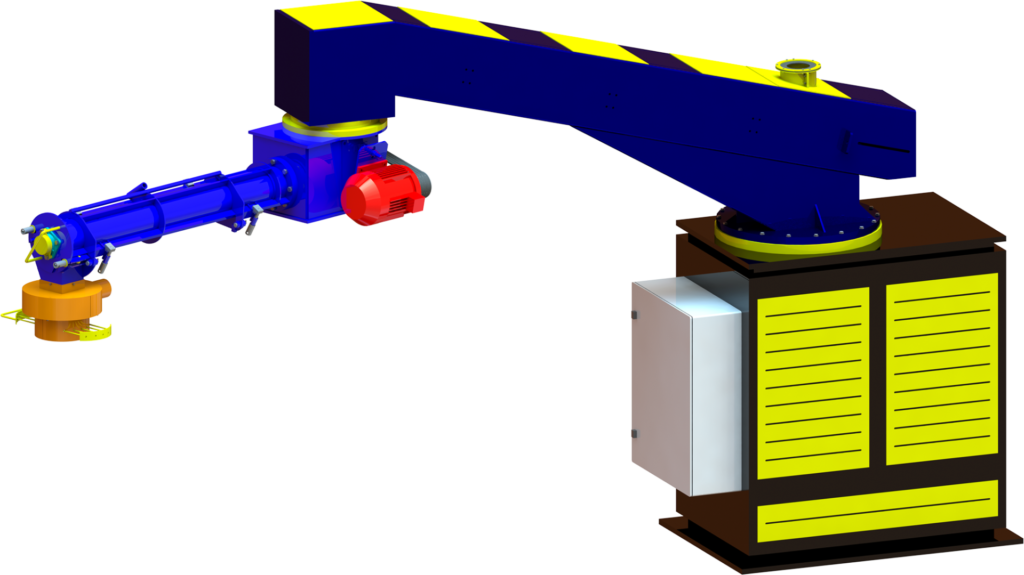

Rotary Table Shot Blasting Machine: Use Cases & Benefits

Over the years working on industrial projects across Africa, I’ve seen countless workshops suffer due to poor surface preparation—paint peeling off, parts sent back for rework, or corrosion setting in within months. And in many of those cases, all they needed was the right machine to do one job right: clean the metal properly. The […]

Top 5 Safety Tips for Shot Blasting Machine Operators

If you’ve ever seen or operated a shot blasting machine, you already know one thing—it’s not forgiving to mistakes. Safety isn’t optional. It’s survival. Here are the top 5 safety tips every shot blasting machine operator must follow to prevent injuries, reduce downtime, and maintain peak efficiency. Shot blasting systems may vary, but one thing […]

What Is a Resin Sand Mixer and Why Does It Matter?

If you’re still relying on manual mixing for resin sand, you’re likely sacrificing consistency and performance in your castings. A resin sand mixer is a specialized machine that combines silica sand, resin, and hardener to create uniform, chemically bonded sand molds—crucial for producing high-quality, dimensionally accurate castings. This article outlines what a resin sand mixer […]

What Is Green Sand Casting And Its Advantages?

Green sand casting isn’t new—but it continues to be a cornerstone in modern metal manufacturing for good reason. Green sand casting uses a moist sand mixture to create molds for metal castings. It’s flexible, economical, and scalable, making it a go-to process for many foundries worldwide. Having worked with foundry equipment for over 20 years, […]

How to Improve Casting Quality with the Right Foundry Equipment

Struggling with casting defects and inconsistent quality? The problem may not be your process—but your equipment. High-quality foundry equipment is essential for reducing casting defects, ensuring dimensional accuracy, and achieving metallurgical consistency. From my experience, even small upgrades to key machines have a measurable effect on casting integrity. Let’s explore how the right equipment can […]

Top 7 Foundry Machines for Small and Medium Foundries

Running a small or medium foundry with limited resources often means fighting an uphill battle to increase output, ensure quality, and keep costs under control. The right foundry machines1 can help small and medium foundries boost productivity, reduce scrap, and build a sustainable path to long-term growth. Over the years, I’ve seen compact, well-chosen machines […]

Foundry Machine Selection: Avoid These 5 Common Mistakes

Choosing the wrong foundry machine can silently drain profits, disrupt operations, and lead to long-term regret. Avoiding common foundry machine selection mistakes is crucial for achieving efficiency, longevity, and a solid return on investment. In my years of working with industrial clients, I’ve seen well-equipped shops fall behind due to one poor equipment decision. Let […]

What Is a Foundry Machine? Complete Beginner’s Guide

Are you struggling to understand what foundry machines actually do? You’re not alone—many manufacturers find the terminology and equipment confusing at first. A foundry machine is a specialized industrial device used to automate the metal casting process, including mold creation, core making, melting, pouring, and finishing. Once I understood how foundry machines work, it completely […]