Rotary Table Shot Blasting Machine: Everything You Need to Know

Tired of spending countless hours fixing coating failures or dealing with surface prep complaints from your paint team? You’re not alone. A rotary table shot blasting machine isn’t just another piece of heavy equipment — it’s often that one missing puzzle piece that makes everything else work smoothly on your shop floor. What Is a […]

Top 7 Mistakes to Avoid When Buying a Resin Sand Molding Recycling Line

Choosing the wrong resin sand molding & recycling line can cripple your casting quality and drive up maintenance costs. Avoid these 7 common mistakes when selecting a resin sand molding line to ensure stable performance, low dust, and long-term reliability. I’ve spent over two decades helping foundries around the world design and optimize their resin […]

Rotary Table Shot Blasting Machine – Perfect Usage Guide

Operating a rotary table shot blasting machine seems simple—but without the right method, you risk inconsistent finishes, higher wear, and longer cycle times. Rotary table shot blasting machines clean medium-to-heavy parts with uniform coverage by rotating the parts under fixed turbines. Proper use ensures efficient, repeatable surface preparation. Here’s how to get the most out […]

Common Challenges in Steel Pipe Surface Preparation and How to Solve Them

Rust, mill scale, pitting—these common surface issues ruin coatings and shorten pipe life. Many projects fail before they even begin due to poor surface prep. Steel pipe surface preparation is the foundation of coating and welding success. Identifying surface issues early and applying targeted shot blasting solutions helps prevent costly failures. In this article, I’ll […]

Twin Rotary Tables Shot Blasting Machine Solution

If you’re still blasting medium-sized parts one by one or manually, you’re wasting time, labor, and consistency. That’s a common problem for many of our customers. A twin rotary table shot blasting machine uses an alternating worktable design to maintain uninterrupted operation, ideal for batch processing with high part repetition. Let me walk you through […]

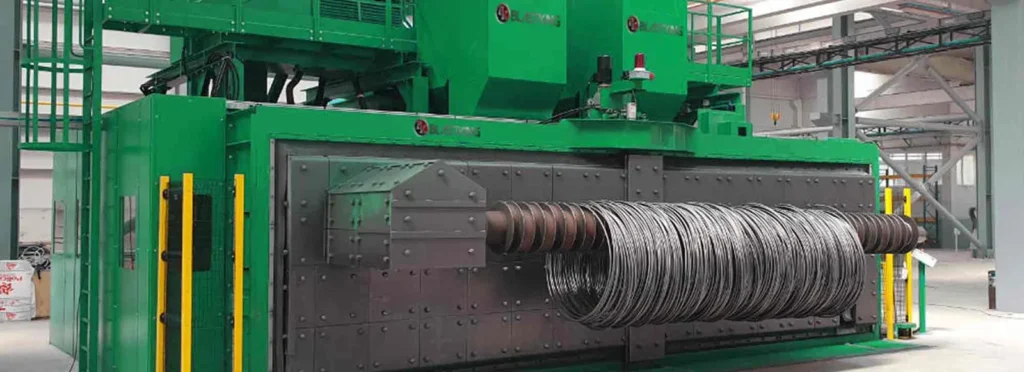

What Is a Wire Rod Shot Blasting Machine and How Does It Work?

Steel wire coils are hard to clean, especially before drawing or coating. Manual methods can’t keep up with modern speed or quality demands. A wire rod shot blasting machine is a continuous inline system that uses high-speed abrasive projection to clean steel wire coils before downstream processing. If your plant deals with wire drawing or […]

Energy-efficient Jolt Squeeze Molding Machines: How to Lower Your Production Costs?

Running a foundry means high energy bills—but what if you could reduce them by nearly half without compromising output? Energy-efficient jolt squeeze molding machines use smarter mechanics and upgraded motors to significantly reduce power consumption while maintaining high-quality compaction. Let’s dive into what makes these machines more efficient—and how your foundry can benefit from the […]

Shot Blasting Machine: The Ultimate Beautician for Industrial Surfaces

Shot blasting is a surface preparation method that uses high-speed abrasive particles—typically metal shots—to clean, descale, or strengthen industrial materials such as steel, concrete, and castings. This process relies on either centrifugal wheels or compressed air to propel steel shots at a high velocity against the surface. It’s a powerful, dry, and eco-friendly method to […]

Top Benefits of Using a Jolt Squeeze Molding Machine?

In real-world foundry operations, problems like loose molds, dimensional inconsistencies, and high labor demand are common. Over the past two decades, I’ve seen jolt squeeze molding machines solve these issues more effectively than any manual method. A jolt squeeze molding machine compacts sand using both jolting (vibration) and squeezing (compression), producing uniform molds that deliver […]

Jolt Squeeze vs Green Sand Molding: Key Differences?

Choosing the wrong molding method can lead to dimensional inaccuracy, wasted material, and serious production delays. Foundries must weigh cost, precision, and scalability carefully. Jolt squeeze molding delivers superior compaction and accuracy, while green sand molding ensures flexibility and cost-efficiency for high-volume runs. Understanding the core differences is critical for making the right investment. Both […]