Surface preparation is a critical component in the construction industry, especially when it comes to ensuring the durability of steel structures. If your steel surfaces are covered in rust, paint, or debris, it can compromise the integrity of your projects. Enter the **Belt Shot Blasting Machine, a powerful tool designed to remove these imperfections and provide the perfect surface for welding, coating, or painting. In this article, we will explore the need for efficient rust removal solutions and why the Belt Shot Blasting Machine could be your ultimate answer.

Belt Shot Blasting Machines are a game changer in the construction industry. These machines not only clean steel surfaces efficiently but also save time, money, and labor. They are an essential tool for any project that involves the treatment of steel, ensuring that the surfaces are primed for the next stage, whether it's coating, painting, or welding. In this article, I'll take you through what these machines are, how they work, and why they're a must-have for your next construction project.

What is a Belt Shot Blasting Machine?

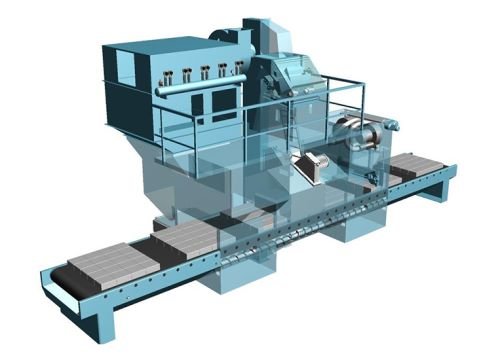

The Belt Shot Blasting Machine is an industrial cleaning tool designed to remove rust, paint, scale, and other contaminants from steel surfaces. It uses centrifugal force to propel abrasive materials, such as steel shots or grit, against the steel surface to clean it. This cleaning method is far superior to traditional methods like hand scraping or chemical cleaning, offering faster and more consistent results.

Key Features:

- Automatic Operation: Belt Shot Blasting Machines are automated, reducing labor and increasing speed.

- Adjustable Speed and Intensity: You can adjust the machine to suit various project needs.

- Consistent Cleaning: Unlike manual methods, the machine ensures even surface treatment, leading to high-quality results.

Dive Deeper into Belt Shot Blasting Machines

Belt Shot Blasting Machines use high-speed rotating belts to carry the steel components through the blasting chamber. Inside, abrasive materials are accelerated by centrifugal force and directed at the surfaces. These machines can handle various sizes of steel components, from small parts to large beams, depending on the machine's specifications.

The key advantage of these machines lies in their precision. The centrifugal force ensures that every inch of the surface is exposed to abrasive action, ensuring complete rust and paint removal. Furthermore, these machines allow for customization of the blasting parameters, such as intensity and coverage, ensuring the best results for different types of surfaces.

By using a Belt Shot Blasting Machine, you're not only enhancing the cleaning process but also improving the overall quality of your construction projects. A cleaner surface leads to better adhesion of coatings, paints, and welds, which ultimately extends the lifespan of the structure.

How Does a Belt Shot Blasting Machine Work?

The operation of a Belt Shot Blasting Machine involves the use of a high-speed rotating conveyor belt to carry steel components through the machine. As these parts move through, the machine uses centrifugal force to hurl abrasive particles (usually steel shot or grit) at the surface. This cleaning process is highly effective in removing surface contaminants such as rust, old paint, and scale.

The key components of a Belt Shot Blasting Machine include:

- Blasting Wheel: A key element that accelerates the abrasive material and directs it at the steel surface.

- Conveyor Belt: Transports the steel components through the blasting area.

- Dust Collection System: Ensures that the dust and debris generated during the blasting process are safely collected, improving air quality and preventing environmental contamination.

Dive Deeper: Belt Shot Blasting Operation Breakdown

When steel components enter the machine, they are moved along a conveyor belt. As the components travel through the blasting chamber, they are exposed to a series of blasting wheels that direct the abrasive particles at them. These abrasive materials strike the surface, removing contaminants like rust, old paint, and dirt.

The intensity and speed of the abrasive action are adjustable, allowing you to customize the cleaning process according to the material or surface type. This makes the machine suitable for various applications in construction projects, from preparing steel beams for welding to cleaning surfaces before applying protective coatings.

The dust collection system integrated into the machine plays a critical role in maintaining a clean environment by capturing airborne dust and debris generated during the blasting process. This feature ensures that your workshop or job site remains free from harmful dust particles, creating a safer and cleaner environment for workers.

What Can a Shot Blasting Machine Clean?

A Shot Blasting Machine can clean a wide range of steel components, including:

- Steel Beams: Essential for structural welding preparation.

- Steel Plates: Often used in the fabrication of industrial structures.

- Reinforced Bars: Crucial for concrete construction.

- Pipe and Tubing: Common in infrastructure and pipeline projects.

- Industrial Equipment: Components of machinery and production lines.

Dive Deeper: Applications of Shot Blasting Machines in Construction

In construction, surface preparation is crucial, and a Belt Shot Blasting Machine can serve many purposes:

- Welding Preparation: Steel beams and other components need a clean surface for welding. Shot blasting removes contaminants that could interfere with the welding process, ensuring precise and strong welds.

- Coating and Painting Preparation: To achieve optimal adhesion for paints and coatings, the surface must be free of contaminants. Shot blasting provides an ideal surface for coatings by removing rust, oil, and scale.

- Infrastructure Projects: Large-scale projects like bridges and highways require thorough surface preparation for steel components. A Belt Shot Blasting Machine can handle large items, ensuring that all surfaces are effectively cleaned and ready for the next phase of construction.

The versatility of Shot Blasting Machines makes them indispensable tools in the construction industry. Whether you are working on small-scale repairs or large infrastructure projects, these machines provide consistent and reliable surface cleaning.

Top Benefits of Using a Belt Shot Blasting Machine for Paint and Rust Removal

4.1 Increased Efficiency

Belt Shot Blasting Machines significantly streamline the cleaning process, eliminating the need for manual labor. Automated operation allows you to clean components faster, increasing the overall efficiency of the project.

4.2 Environmentally Friendly

By removing the reliance on chemical cleaners, Belt Shot Blasting Machines are a greener option. The abrasive materials can be reused multiple times, minimizing waste and reducing environmental impact.

4.3 Versatility

These machines can handle a variety of steel components, regardless of size or shape. From small rods to large steel plates, the Belt Shot Blasting Machine is adaptable to different project needs.

4.4 Superior Surface Preparation

The high-intensity abrasive action ensures that surfaces are thoroughly cleaned, leading to improved adhesion of coatings and paints. This results in longer-lasting finishes and more durable structures.

How to Choose the Right Belt Shot Blasting Machine for Your Needs

Factors to Consider:

| Factor | Considerations |

|---|---|

| Project Scale | Machine capacity and throughput needed. |

| Surface Type | Compatibility with different steel surfaces. |

| Maintenance Needs | Durability, ease of use, and regular upkeep. |

When choosing a Belt Shot Blasting Machine, consider the scale of your project, the types of steel components you are working with, and the machine's maintenance requirements. You want a machine that not only meets your current needs but can also accommodate future growth.

Best Practices for Using a Belt Shot Blasting Machine

Tips for Optimized Performance:

- Regular Maintenance: Regular checks and cleaning of the machine are essential to ensure consistent performance.

- Operator Training: Proper training ensures that operators use the machine effectively, minimizing errors and improving efficiency.

- Appropriate Abrasive Selection: Choose the right type of abrasive material for the job to achieve the desired surface finish.

Conclusion

A Belt Shot Blasting Machine is an indispensable tool for any construction project that involves steel components. With its ability to efficiently remove rust, paint, and contaminants, it ensures high-quality surface preparation for welding, coating, and painting. By choosing the right machine and using it effectively, you can significantly improve the efficiency, safety, and durability of your construction projects.

Explore how a Belt Shot Blasting Machine can transform your workflow and deliver exceptional results for your next project.