When searching for a shot blasting machine, buyers often have concerns about efficiency, cost-effectiveness, and long-term maintenance. The challenge is not just about selecting a machine but ensuring that it meets specific production requirements, reduces operational costs, and improves surface quality.

The best shot blasting machine should align with your industry needs, optimize production, and minimize costs. Understanding key factors such as machine type, media selection, automation, and manufacturer reputation will help you make an informed decision.

Choosing the right machine is a long-term investment. Let’s dive into the core aspects that will help you find the perfect solution.

1. What Are Your Application and Industry Requirements?

Buyers need to determine how a shot blasting machine will fit into their specific industry processes. Will it be used for descaling, cleaning, or preparing surfaces for coatings?

Industry requirements dictate the type of machine needed. Machines for steel fabrication differ from those used in aerospace or automotive applications, so identifying the right fit is crucial for efficiency.

Industry-Specific Considerations

| Industry | Common Shot Blasting Applications |

|---|---|

| Automotive | Cleaning, deburring, surface roughening for coating |

| Aerospace | Surface preparation for precision parts |

| Steel Fabrication | Descaling, rust removal, and painting prep |

| Foundries | Removing sand and scale from castings |

The right choice ensures higher productivity, cost savings, and a flawless finish.

2. What Type of Shot Blasting Machine Do You Need?

Different applications require different shot blasting machines. Buyers often search for a machine that fits their workload and material specifications.

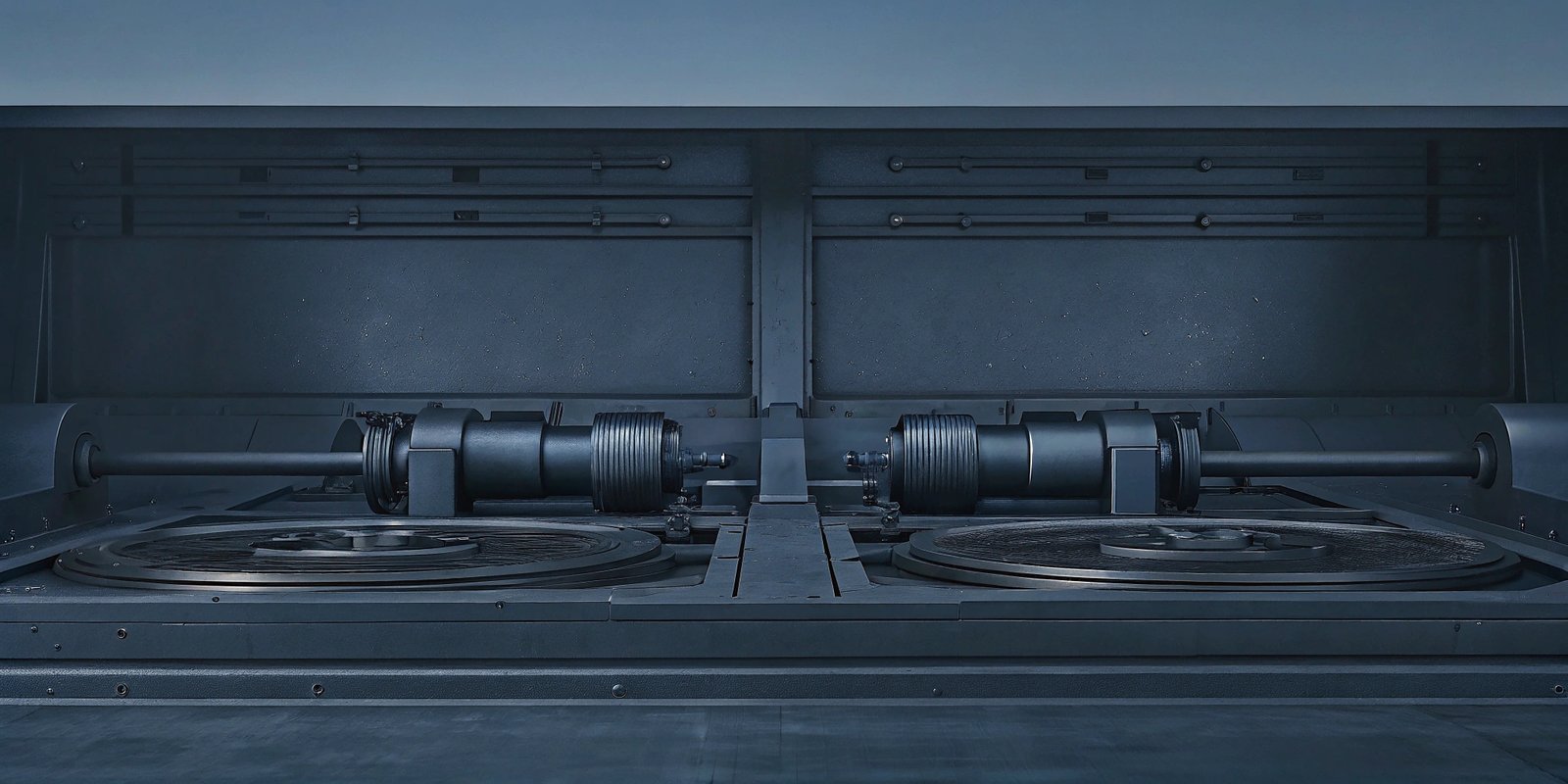

Understanding the types—such as tumble belt, hanger type, table type, and continuous shot blasting machines—helps you avoid purchasing an inefficient system.

Machine Type Overview

| Machine Type | Best For | Key Advantages |

|---|---|---|

| Tumble Belt | Small parts, batch processing | Efficient for bulk cleaning |

| Hanger Type | Large and delicate parts | No part-on-part impact |

| Rotary Table | Heavy or irregularly shaped parts | Even blasting coverage |

| Continuous Conveyor | High-volume production | Fully automated and fast |

Consider production volume, material type, and space requirements before making a decision.

3. What Media and Abrasive Type Will You Use?

The type of abrasive media used directly impacts surface finish, machine longevity, and production costs. Many users search for the best media for their specific materials.

Choosing the wrong abrasive can lead to excessive machine wear or subpar results. Understanding the impact of different abrasives on your material is key.

Common Abrasive Media and Their Uses

| Abrasive Type | Best For | Surface Effect |

|---|---|---|

| Steel Shot | Heavy-duty descaling | Smooth and polished |

| Aluminum Oxide | Surface prep for coatings | Rough texture |

| Glass Beads | Delicate materials | Satin finish |

Consulting a supplier for media recommendations can prevent costly errors.

4. What is the Machine's Capacity and Production Speed?

Production capacity is a major concern for buyers. Many searches revolve around optimizing throughput while maintaining quality.

The blasting chamber size, conveyor speed, and media recycling system determine the output. Investing in a machine that aligns with production targets ensures maximum efficiency.

Consider future expansion needs when selecting machine capacity.

5. What Are the Maintenance and Operational Costs?

Buyers often research the total cost of ownership. Beyond the purchase price, they want to know about ongoing maintenance, energy efficiency, and spare parts availability.

High-maintenance machines lead to increased downtime and expenses. Look for machines with durable wear parts, efficient media recycling, and energy-saving features.

Key Maintenance Factors to Consider

- Wear parts longevity: Machines with reinforced liners last longer.

- Ease of media recycling: Reduces abrasive waste and cuts costs.

- Energy efficiency: Lower power consumption improves ROI.

6. Is the Machine Equipped with Automation and Smart Controls?

Automation is a growing priority. Many buyers look for features that reduce labor costs and enhance process consistency.

Modern shot blasting machines come with programmable controls, IoT-based monitoring, and automated loading systems to streamline operations.

Benefits of Automation in Shot Blasting

| Feature | Benefit |

|---|---|

| PLC-Based Control | Precise blasting parameters |

| IoT Connectivity | Remote monitoring and predictive maintenance |

| Automated Loading | Reduces manual labor and increases speed |

Investing in automation can significantly boost productivity.

7. What is the Reputation and Support of the Manufacturer?

Reliability is a top concern for industrial buyers. Searches often include manufacturer reviews, support options, and warranty policies.

Choosing a reputable supplier ensures access to high-quality machines, technical support, and spare parts when needed.

How to Evaluate a Manufacturer

- Check industry experience: A track record of successful installations.

- Read customer testimonials: Insights into real-world performance.

- Ask about warranties: Extended warranties indicate confidence in product durability.

Conclusion

To truly address customer search intent, this guide provides in-depth insights into selecting the right shot blasting machine. By considering application needs, machine types, abrasive media, capacity, maintenance, automation, and manufacturer reputation, buyers can make an informed decision that enhances efficiency and reduces costs. Investing in the right equipment ensures long-term success in industrial applications.