Introduction

Shot blasting is an effective surface treatment method used to clean rust, remove debris, and prepare metal surfaces for further processing. It plays a crucial role across multiple industries, enhancing operational efficiency, product quality, and durability.

By effectively removing contaminants, it ensures a high-quality finish that improves adhesion for coatings and paints. This process is widely used in industries such as automotive, foundry, aerospace, and manufacturing to extend the lifespan of metal products while reducing maintenance costs.

What is Shot Blasting?

This mechanical process involves propelling abrasive media at high velocity onto metal surfaces to remove contaminants and enhance surface quality. There are two primary types:

- Air Blasting: Uses compressed air to propel abrasive particles for precise surface cleaning, making it ideal for delicate or detailed components.

- Wheel Blasting: Employs a high-speed rotating wheel to accelerate media for large-scale applications, commonly used in industrial settings.

Benefits

- Effective rust and scale removal, ensuring a clean surface for subsequent processing.

- Superior surface preparation for coatings, improving adhesion and longevity.

- Extended lifespan of metal products, reducing wear and tear over time.

Key Applications Across Industries

1. Foundry Applications

Use Case: Cleaning metal castings post-production to remove residual sand and contaminants.

Process: After metal components are cast, they often retain surface impurities such as excess sand or scale. Shot blasting effectively removes these residues, ensuring the final product meets quality standards.

Benefits:

- Efficient processing of small and intricate castings, allowing for bulk cleaning with minimal labor.

- Ensures smooth, defect-free surfaces, which is critical for further machining or coating.

- Improves adhesion for coatings and paints, leading to higher durability of finished components.

2. Automotive Industry

Use Case: Preparing car parts such as bell housings, stabilizing bars, and engine components for painting and finishing.

Process: Automotive manufacturers rely on shot blasting to remove rust, scale, and other surface impurities, ensuring better adhesion for paint and coatings.

Benefits:

- Enables the use of lightweight metals for fuel efficiency, which contributes to improved vehicle performance.

- Enhances paint adhesion and surface durability, leading to a longer-lasting and visually appealing finish.

- Supports the production of high-performance, long-lasting components, reducing premature wear and corrosion.

3. Manufacturing and Metal Production

Use Case: Removing rust, corrosion, and surface imperfections during production.

Process: During manufacturing, metal parts can accumulate rust or oxidation. Shot blasting effectively removes these impurities before final assembly or coating.

Industries Served: Aerospace, construction, industrial manufacturing.

Benefits:

- Improves surface quality for final coatings, ensuring a flawless and durable finish.

- Ensures product reliability and longevity, preventing defects that may arise from untreated surfaces.

4. Propane and Medical Tank Maintenance

Use Case: Cleaning propane tanks and medical gas cylinders exposed to environmental conditions.

Process: Tanks and cylinders must be free from rust and coatings before repainting or re-coating. Shot blasting efficiently removes old layers and prepares surfaces for reapplication.

Benefits:

- Prepares surfaces for repainting and recoating, ensuring compliance with safety regulations.

- Extends service life and enhances safety, reducing risks of leaks or corrosion.

- Specialized equipment ensures efficient processing, minimizing downtime and labor costs.

Customizable Systems for Specific Needs

1. Chain Mesh Belt Systems

- Ideal for: Small or intricate parts that require delicate handling.

- Features: Customizable design, minimal part damage, quick processing for high throughput operations.

2. Roller Table Conveyor Systems

- Ideal for: Structural steel and large metal plates, used in construction and heavy industries.

- Features: Efficient surface cleaning for large-scale components with high uniformity.

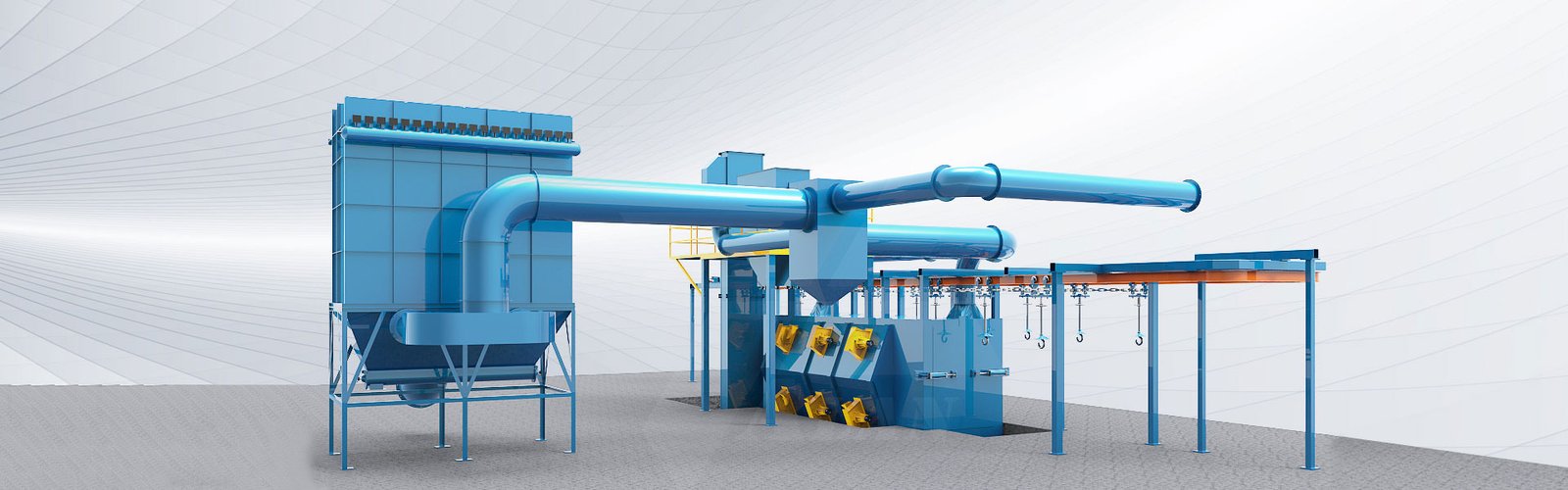

3. Monorail Conveyor Systems

- Ideal for: Facilities with overhead monorail systems that need integrated shot blasting solutions.

- Features: Easy integration, adaptable work envelope, and high automation potential.

4. Skew Roll Conveyor Systems

- Ideal for: Cylinders, pipes, and rods that require complete 360-degree cleaning.

- Features: Rotational blasting ensures even surface treatment without manual adjustments.

5. Spinner Hanger Systems

- Ideal for: Irregularly shaped or heavy components used in manufacturing and industrial applications.

- Features: Versatile, industrial-grade heavy-duty processing, suitable for a wide range of materials.

6. Table Blast Equipment

- Ideal for: Heavy parts unsuitable for tumbling or bulk processing.

- Features: Rotating table design for even exposure to blast wheels, ensuring consistent results.

7. Tumble Blast Equipment

- Ideal for: High-volume production with small, durable parts.

- Features: Gentle tumbling action for bulk processing without surface damage.

8. Shot Peening Machines

- Ideal for: Strengthening metal surfaces to enhance fatigue resistance.

- Features: Precision-controlled blasting for improved material durability and structural integrity.

Benefits Across Industries

- Improved Surface Quality: Removes rust, corrosion, and contaminants, ensuring better product finishing.

- Enhanced Durability: Prepares surfaces for coatings and extends lifespan, preventing premature failure.

- Increased Efficiency: Speeds up production while maintaining consistency and high-quality standards.

- Cost-Effectiveness: Reduces maintenance costs and prolongs component life, lowering overall operational expenses.

- Environmental Sustainability: Uses recyclable abrasive materials and reduces waste, promoting eco-friendly manufacturing.

How to Choose the Right Equipment for Your Needs

Consider the following factors to select the most efficient and cost-effective shot blasting machine:

- Material Type: Different metals require different blasting intensities and media types.

- Part Shape and Size: Small, intricate, heavy, or large components need specialized equipment.

- Production Volume: Whether you require high-volume processing or customized solutions.

- Desired Outcome: The choice depends on whether the goal is cleaning, surface preparation, or finishing.

Expert Recommendation

Consult industry specialists to determine the best equipment for your specific needs. Selecting the right machine ensures optimal performance and cost-efficiency.

Conclusion

This surface treatment method is crucial for industries such as automotive, metal manufacturing, and tank maintenance. It ensures cleaner surfaces, better adhesion, and long-lasting durability.

Explore different customizable options to enhance efficiency, improve product quality, and optimize business operations.