Steel pipes are prone to rust, welding slag, and oxidation, which weaken their structural integrity. If not properly treated, they may fail under pressure, leading to costly repairs and potential hazards.

Steel pipe shot blasting machines effectively remove surface contaminants from both the inner and outer walls, enhancing durability, adhesion, and corrosion resistance. This process extends the lifespan of steel pipes while improving their mechanical properties.

To understand why these machines are indispensable, let's explore their key advantages in detail.

What Makes Steel Pipe Shot Blasting Machines So Effective?

Steel pipe shot blasting machines use high-speed projectiles to remove rust, scale, and welding residues from both the exterior and interior surfaces. This results in a smooth, clean finish that enhances coating adhesion and improves fatigue resistance.

These machines operate with centrifugal cantilever shot blasting technology, providing high-speed, uniform cleaning while reducing maintenance costs. They are widely used in industries like oil & gas, shipbuilding, and construction.

How Does the Cleaning Process Work?

| Step | Description |

|---|---|

| 1. Loading | Pipes are fed into the machine on a conveyor system. |

| 2. Outer Wall Blasting | High-speed projectiles clean the external surface. |

| 3. Inner Wall Blasting | Mobile shot blasting nozzles clean the inner surface. |

| 4. Abrasive Recovery | Projectiles are collected and separated from debris. |

| 5. Final Inspection | Cleaned pipes are checked for quality. |

This method ensures thorough, efficient cleaning without damaging the structural integrity of the pipe.

Enhanced Corrosion Resistance and Durability

Corrosion is a major issue for steel pipes, especially in industries like oil & gas, where exposure to moisture and chemicals accelerates degradation.

Shot blasting removes corrosive elements and creates a roughened surface that enhances the adhesion of protective coatings, significantly increasing the pipe’s lifespan.

Dive Deeper: How Shot Blasting Improves Durability

Shot blasting doesn't just clean steel pipes—it strengthens them. The process enhances:

- Fatigue Resistance: Reduces microcracks that can develop under stress.

- Surface Adhesion: Ensures coatings bond more effectively.

- Mechanical Strength: Increases resistance to bending and compression.

Pipelines exposed to harsh environments, such as underwater oil rigs, must withstand extreme pressure. Shot blasting plays a crucial role in ensuring long-term performance and safety.

Cost-Effective Maintenance and Efficiency

Manual surface cleaning methods like sandblasting are labor-intensive and inconsistent. Shot blasting machines automate the process, reducing operational costs while maintaining superior quality.

| Factor | Manual Cleaning | Shot Blasting Machine |

|---|---|---|

| Labor Costs | High | Low (automated process) |

| Cleaning Speed | Slow | Fast |

| Surface Uniformity | Inconsistent | Highly consistent |

| Material Waste | High | Low (abrasives are recycled) |

By optimizing the cleaning process, manufacturers can save on labor, reduce downtime, and achieve better results.

Superior Cleaning Performance with Advanced Technology

Steel pipe shot blasting machines use state-of-the-art technology to achieve maximum efficiency and precision.

Key Technological Features

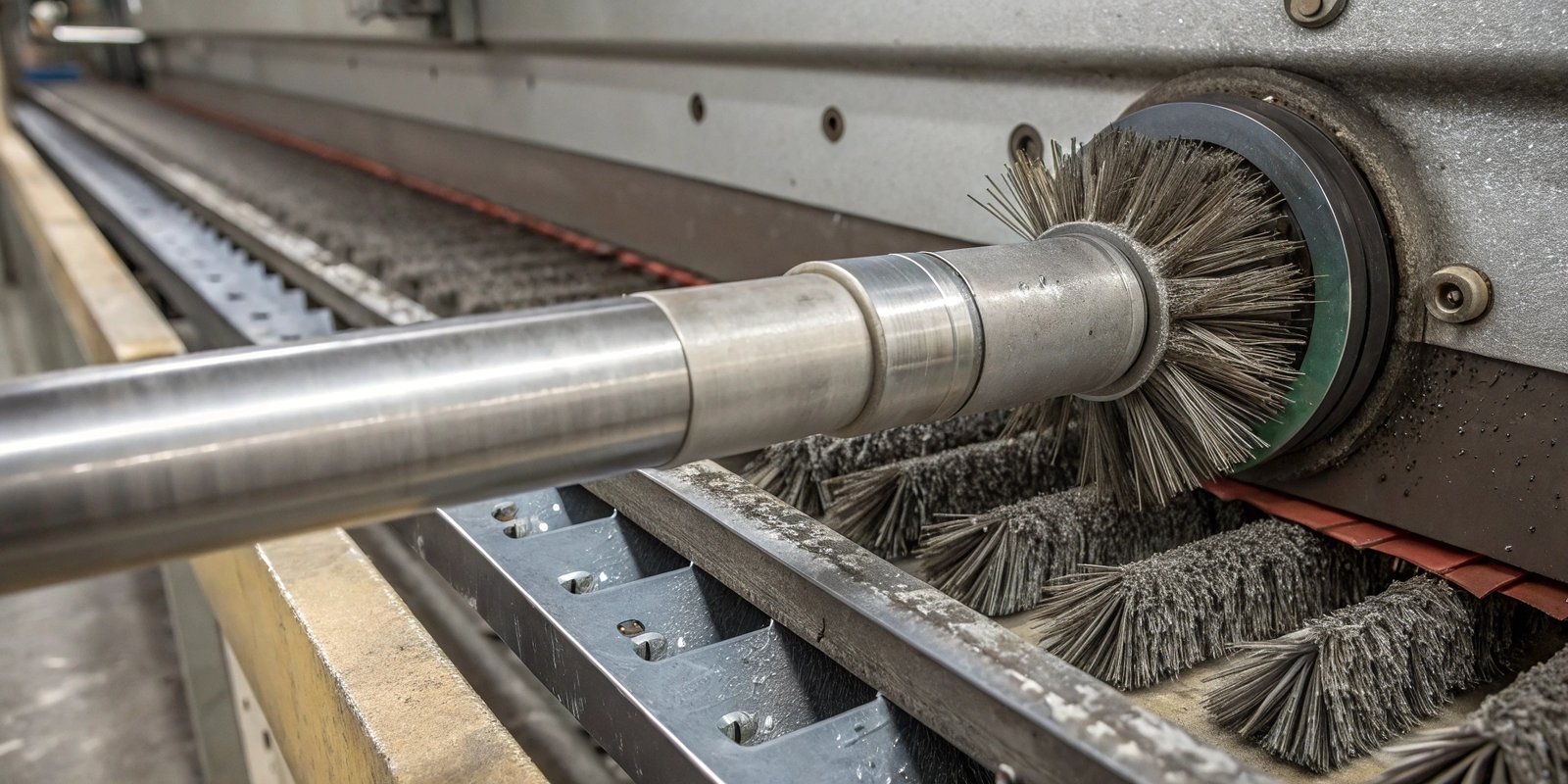

- Centrifugal Cantilever Shot Blasting System – Ensures high-speed, high-capacity blasting for uniform cleaning.

- Multi-Layer Sealing Brushes – Prevents projectile leakage, allowing seamless cleaning of pipes with different diameters.

- Full Curtain BE-Type Shot Slag Separator – Improves separation efficiency and reduces wear on the blasting system.

- Automatic Recovery System – Recycles abrasives for continuous operation, reducing material waste.

This technology guarantees faster cleaning, lower maintenance, and reduced operational costs.

Environmental and Safety Benefits

Traditional pipe cleaning methods often generate excessive dust, waste materials, and environmental pollutants. In contrast, shot blasting is an eco-friendly process that minimizes waste and enhances workplace safety.

How Shot Blasting Contributes to Sustainability

- Dust Filtration Systems: Reduces airborne particles, improving air quality.

- Abrasive Recycling: Cuts down on material waste.

- Noise Reduction Technology: Creates a safer working environment.

By investing in modern shot blasting solutions, companies can comply with environmental regulations while maintaining high safety standards.

My Insights

Steel pipe shot blasting machines are essential for industries requiring durable, corrosion-resistant pipelines. The ability to clean both inner and outer surfaces efficiently makes them invaluable for manufacturing, construction, and energy sectors.

From my experience, investing in a high-quality shot blasting system leads to higher productivity, better product quality, and long-term cost savings. Modern advancements, such as automated abrasive recovery and multi-layer sealing brushes, further enhance operational efficiency and performance.

Conclusion

Steel pipe shot blasting machines offer unmatched efficiency, durability, and cost-effectiveness compared to manual cleaning methods. They enhance corrosion resistance, improve coating adhesion, and ensure a longer lifespan for steel pipes.

For manufacturers looking to optimize their surface treatment processes, investing in a shot blasting system is a smart, future-proof decision.