Transporting large, rusted equipment off-site for surface treatment is costly and time-consuming.

Portable sand blasting machines let you bring industrial-grade cleaning directly to the job site—cutting downtime, costs, and delays.

They’re changing the way contractors, maintenance teams, and field engineers manage surface preparation. Here's why on-site blasting with portable units is a smart investment in 2025.

1. On-Site Mobility That Reduces Downtime

Large machines or steel structures often require disassembly and transport—slowing everything down.

Portable sand blasting machines eliminate the need to move heavy equipment, allowing work to happen immediately and on location.

Whether you're restoring a bridge, servicing a marine vessel, or working in a desert pipeline site, mobility equals speed. I’ve seen projects that would normally take 7–10 days shrink to just 3 thanks to onsite preparation.

| Scenario | Traditional Setup | Portable Blaster |

|---|---|---|

| Equipment Cleaning | Transport to facility | Clean on location |

| Part Disassembly | Required | Not required |

| Setup Time | High | Low (under 1 hour) |

| Operational Disruption | Full shutdown | Partial or zero |

2. Lower Project Costs Without Compromising Quality

Shipping oversized components is expensive—not to mention manpower for loading and unloading.

Using portable machines cuts out logistics costs and reduces the labor required for setup and transport.

These savings don’t mean lower quality. Modern portable systems use high-efficiency nozzles and powerful compressors to match fixed machine output.

For a highway overpass project, one contractor told me they saved nearly $18,000 in transport and labor fees over two months—just by switching to portable units.

3. Faster Job Completion and Project Turnaround

Project delays are expensive—whether you're billed hourly or face penalties.

Portable sand blasters allow teams to start prep work immediately, cutting days off overall project timelines.

Industries that benefit include:

- Shipbuilding – No dock delay due to waiting for treatment slots

- Pipeline Repair – Surface prep done on-site in real-time

- Construction – Steel beams can be cleaned directly at erection points

Less time spent waiting = more time finishing the job.

4. High-Quality Surface Preparation Across Conditions

Think mobile means weaker performance? Think again.

Portable sand blasting machines provide excellent results for rust removal, etching, descaling, and paint stripping—on any surface.

They’re compatible with most commercial abrasives: garnet, aluminum oxide, glass bead, or steel grit. With adjustable pressure controls, they can prep surfaces for:

- Coating

- Painting

- Welding

- Inspection

Our clients in offshore maintenance regularly use portable units to meet ISO 8501-1 standards even in marine environments.

5. Wide Industry Versatility

Portable sand blasting is no longer a niche tool—it’s an industry staple.

🧱 Construction – Structural steel prep, concrete surface roughening

🚗 Automotive – Frame cleaning, paint removal

🚢 Shipbuilding – Barnacle and corrosion removal on hulls

🛢 Oil & Gas – Pipeline descaling, tank rehab

🏭 Industrial Maintenance – Heavy machinery restoration

The same unit can be adapted to different job sites with minor nozzle or media changes, making it a multipurpose asset.

6. Quick Setup for Immediate Use

No technician wants to spend half a shift setting up gear.

Most portable sand blasting machines are plug-and-play with modular parts, making setup fast and simple.

Key setup features:

| Feature | Benefit |

|---|---|

| Modular Components | Easy to move and assemble |

| Intuitive Controls | Minimal training required |

| Compact Design | Fits in trucks or site cages |

| Quick-Connect Hoses | Ready in 15–30 minutes |

Some models even come with self-diagnostics and error codes for troubleshooting on-site.

7. Environmentally Responsible Blasting

Concerns about airborne dust and media waste are real—but addressable.

Today’s portable units come with dust suppression systems, recyclable media, and eco-compatible filters.

This means:

- Safer working conditions

- Easier compliance with environmental regulations

- Less abrasive waste generation

I've worked with municipal contractors who needed to meet strict urban air standards. Their portable units passed every on-site EPA inspection—thanks to built-in HEPA-grade filters and containment skirts.

8. Minimized Risk of Damaging Sensitive Surfaces

Some jobs require finesse—like blasting delicate alloys or painted components for refurbishing.

Portable machines offer precise control of blast pressure, nozzle size, and abrasive type—protecting fragile surfaces.

Settings can be adjusted for:

- Thin aluminum panels

- Composite materials

- Precision-cast parts

- Wood or plastic surfaces

This makes them ideal for museum restorations, aviation repairs, or high-end vehicle work.

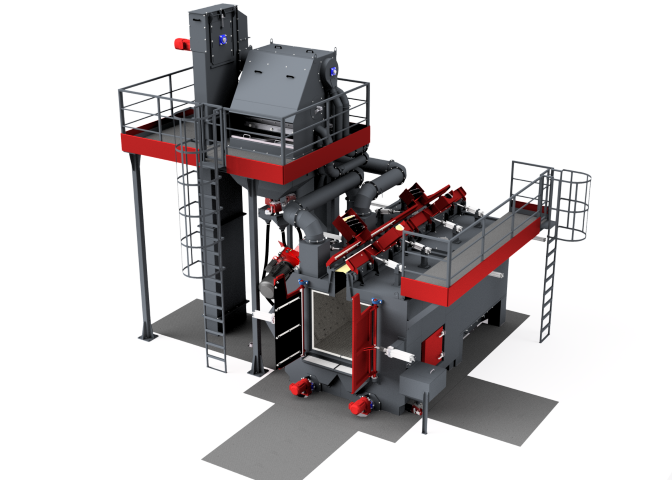

9. Simplifies Cleaning of Large and Bulky Equipment

Dismantling a 3-ton machine for cleaning? Not anymore.

With portable sand blasting, you treat heavy or large items in place—no cranes, no teardown.

From mining haul trucks to industrial turbines, these machines allow you to clean everything in situ. That saves time, reduces risk, and preserves alignment or calibration of complex equipment.

Use cases include:

- Agricultural trailers

- Structural beams

- Powerplant turbines

- Train chassis and axles

Choosing the Right Portable Sand Blasting Machine

Not all portable units are created equal. Here’s what to evaluate before buying:

| Factor | Why It Matters |

|---|---|

| Abrasive Compatibility | Supports the media needed for your application |

| Compressor Size | Ensures consistent pressure output |

| Dust Control | Keeps site compliant and clean |

| Build Quality | Longevity under rugged conditions |

| Certifications | CE, ISO for global safety and quality standards |

| Parts & Support | Fast access to spares and technical help |

Always choose a model that fits your environment, material type, and volume of work.

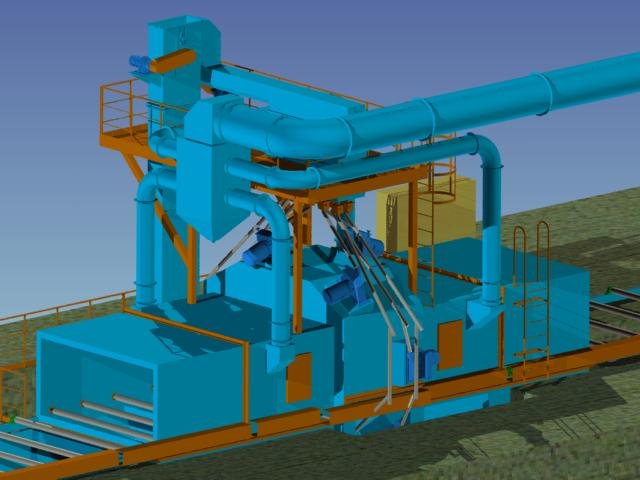

Recommended Manufacturer: Why Aerowheel Surface Finishing Stands Out

Among the crowd of portable sand blasting machine suppliers, Aerowheel Surface Finishing continues to earn trust.

What Makes Them Stand Out:

- ✅ ISO-Certified Products – Tested for performance and safety

- 🔄 Custom Solutions – Tailored to specific industrial needs

- 🌱 Eco Innovation – Dust containment and abrasive recycling

- 📞 Responsive Support – Global service with local partners

Aerowheel’s commitment to field-ready solutions and continuous innovation makes them a top choice for contractors and engineers alike.

Conclusion: A Smart Investment for On-Site Productivity

Portable sand blasting machines aren’t just a trend—they’re a strategic advantage.

They save time, reduce costs, and offer unmatched flexibility across industries and job sites.

If you’re ready to transform your surface prep operations, contact a certified supplier today to find the right portable solution for your needs.