Metal surface treatment is crucial for enhancing durability, appearance, and performance. But how do you decide between shot blasting and shot peening?

Shot blasting is primarily used for cleaning and surface preparation, while shot peening is used to enhance fatigue resistance and mechanical properties. The choice depends on whether your priority is surface finish or structural strength.

Selecting the wrong process can lead to inefficiencies and increased costs. Understanding their differences will help you make the best choice for your specific application.

What is the Primary Purpose of Your Surface Treatment?

Metal treatment processes vary based on the final goal. Are you preparing a surface for painting, or do you need to strengthen the workpiece?

Shot blasting is the right choice if your goal is to remove rust, scale, or contaminants from the surface. Shot peening is ideal if you need to improve fatigue resistance and mechanical properties.

Dive Deeper: Surface Preparation vs. Structural Strength

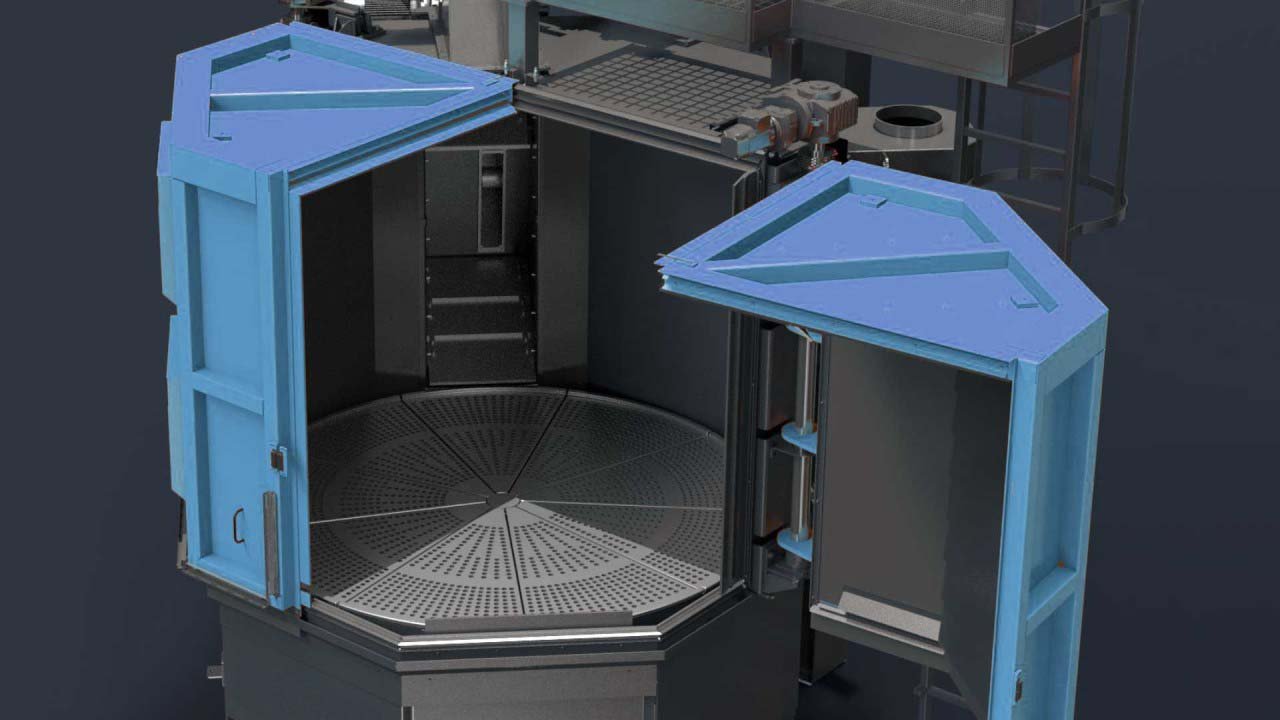

Shot blasting works by propelling abrasive media at high speeds to remove impurities, creating a clean surface for coatings or further machining. Industries such as automotive, construction, and shipbuilding use shot blasting extensively.

Shot peening, on the other hand, introduces compressive stress by striking the metal surface with small, round media. This process prevents crack propagation and is essential in aerospace, automotive, and high-performance manufacturing.

| Process | Primary Purpose | Common Applications |

|---|---|---|

| Shot Blasting | Cleaning & Preparation | Removing rust, mill scale, and old coatings |

| Shot Peening | Strengthening & Durability | Enhancing fatigue resistance and preventing stress corrosion |

What Type of Metal Workpiece Are You Treating?

Not all materials react the same way to shot blasting or shot peening. The type, thickness, and function of your metal workpiece influence the ideal choice.

Thick, heavy-duty materials benefit from shot blasting, while thinner or high-stress components require shot peening.

Dive Deeper: Material Compatibility

Shot blasting is widely used for cleaning steel plates, pipes, castings, and welded structures. The process is aggressive, making it unsuitable for delicate or thin-walled components.

Shot peening is commonly applied to springs, gears, turbine blades, and aerospace components. The controlled process prevents premature failure in fatigue-prone materials.

| Material Type | Recommended Process | Why? |

|---|---|---|

| Thick Steel Plates | Shot Blasting | Efficient rust and scale removal |

| Turbine Blades | Shot Peening | Improves fatigue life and prevents cracking |

| Welded Structures | Shot Blasting | Prepares surface for coatings |

| Suspension Springs | Shot Peening | Increases durability and lifespan |

Do You Require a Smooth or Compressive Surface Finish?

Surface roughness and mechanical properties play a key role in deciding between shot blasting and shot peening.

Shot blasting creates a rough surface ideal for coatings, while shot peening smooths the surface and improves mechanical integrity.

Dive Deeper: Roughness vs. Strength Enhancement

Shot blasting is widely used for cleaning steel plates, pipes, castings, and welded structures. The process is aggressive, making it unsuitable for delicate or thin-walled components.

Shot peening is commonly applied to springs, gears, turbine blades, and aerospace components. The controlled process prevents premature failure in fatigue-prone materials.

| Material Type | Recommended Process | Why? |

|---|---|---|

| Thick Steel Plates | Shot Blasting | Efficient rust and scale removal |

| Turbine Blades | Shot Peening | Improves fatigue life and prevents cracking |

| Welded Structures | Shot Blasting | Prepares surface for coatings |

| Suspension Springs | Shot Peening | Increases durability and lifespan |

Do You Require a Smooth or Compressive Surface Finish?

Surface roughness and mechanical properties play a key role in deciding between [shot blasting](https://vikingcorporation.com/applications-and-uses-of-shot-blasting/) and shot peening.

Shot blasting creates a rough surface ideal for coatings, while shot peening smooths the surface and improves mechanical integrity.

Conclusion

Choosing between shot blasting and shot peening depends on your treatment objective, workpiece material, and desired surface finish. If your goal is cleaning and preparation, go with shot blasting. If you need durability and strength enhancement, opt for shot peening. Selecting the right process ensures optimal performance, efficiency, and cost-effectiveness for your metal components.