Choosing the wrong air compressor for sandblasting can lead to inconsistent results, wasted time, and costly downtime. Without sufficient airflow or pressure, the efficiency and quality of your sandblasting process are severely impacted.

The right size air compressor ensures consistent airflow, optimal pressure, and smooth operation, whether for personal or industrial use.

This guide provides a detailed breakdown of air compressor sizing, CFM and PSI requirements, and compressor types to help you make the best decision for your sandblasting needs.

Introduction: The Importance of the Right Air Compressor for Sandblasting

Sandblasting demands high-powered, efficient air compressors capable of handling abrasive materials and maintaining consistent pressure.

Key factors such as CFM (Cubic Feet per Minute) and PSI (Pounds per Square Inch) play a crucial role in ensuring optimal performance, reducing downtime, and achieving better results.

Dive Deeper: Benefits of Choosing the Right Compressor

- Efficiency: Consistent pressure improves the speed and quality of sandblasting.

- Reduced Downtime: Sufficient air supply prevents interruptions during operation.

- Better Results: Ensures uniform cleaning, coating removal, and surface preparation.

| Factor | Why It Matters |

|---|---|

| CFM | Ensures adequate airflow for abrasive propulsion. |

| PSI | Maintains consistent pressure for effective blasting. |

| Tank Size | Reduces cycling frequency for prolonged use. |

Understanding Air Compressors for Sandblasting

What Is an Air Compressor in Sandblasting?

An air compressor provides the high-pressure air required to propel abrasive materials onto surfaces, effectively removing rust, paint, and other contaminants.

Key considerations include air pressure, volume, and horsepower to ensure reliable and efficient operation.

Why the Right Compressor Size Matters

Using a compressor that’s too small leads to inconsistent pressure, interruptions, and wasted time. A properly sized compressor guarantees smooth operation and professional results.

| Compressor Feature | Impact on Sandblasting |

|---|---|

| Air Pressure (PSI) | Enables effective abrasive propulsion. |

| Air Volume (CFM) | Determines continuous operation without interruptions. |

Types of Sandblasters and Their Compressor Needs

Selecting the right sandblaster type is essential for optimizing compressor performance.

Gravity-Fed Sandblasters

- How They Work: Sand and air are mixed in a pressurized canister for direct propulsion.

- Air Compressor Requirements: High airflow and pressure; suited for industrial applications.

Siphon Sandblasters

- How They Work: Sand is drawn through a hose using suction created by compressed air.

- Air Compressor Requirements: Steady airflow with lower pressure than other types.

| Sandblaster Type | Compressor Requirements |

|---|---|

| Gravity-Fed | Moderate PSI, small to medium tasks. |

| Pressure | High PSI and CFM, industrial use. |

| Siphon | Lower PSI, steady airflow. |

Choosing the Right Size Air Compressor for Sandblasting

CFM (Cubic Feet per Minute)

CFM measures the volume of air the compressor can supply. Sandblasting requires high CFM to maintain consistent airflow.

Recommendations:

- General sandblasting: 18–35 CFM.

- Industrial applications: 50–100+ CFM.

PSI (Pounds per Square Inch)

PSI determines the pressure at which air is delivered. Effective sandblasting requires sufficient PSI to propel abrasives efficiently.

Recommendations:

- Maintain 90–100 PSI for optimal blasting.

- Avoid letting PSI drop below 50, as it disrupts efficiency.

| Specification | Recommendation |

|---|---|

| CFM | 18–35 (general), 50–100+ (industrial). |

| PSI | 90–100 (optimal), 50 minimum. |

Types of Air Compressors for Sandblasting

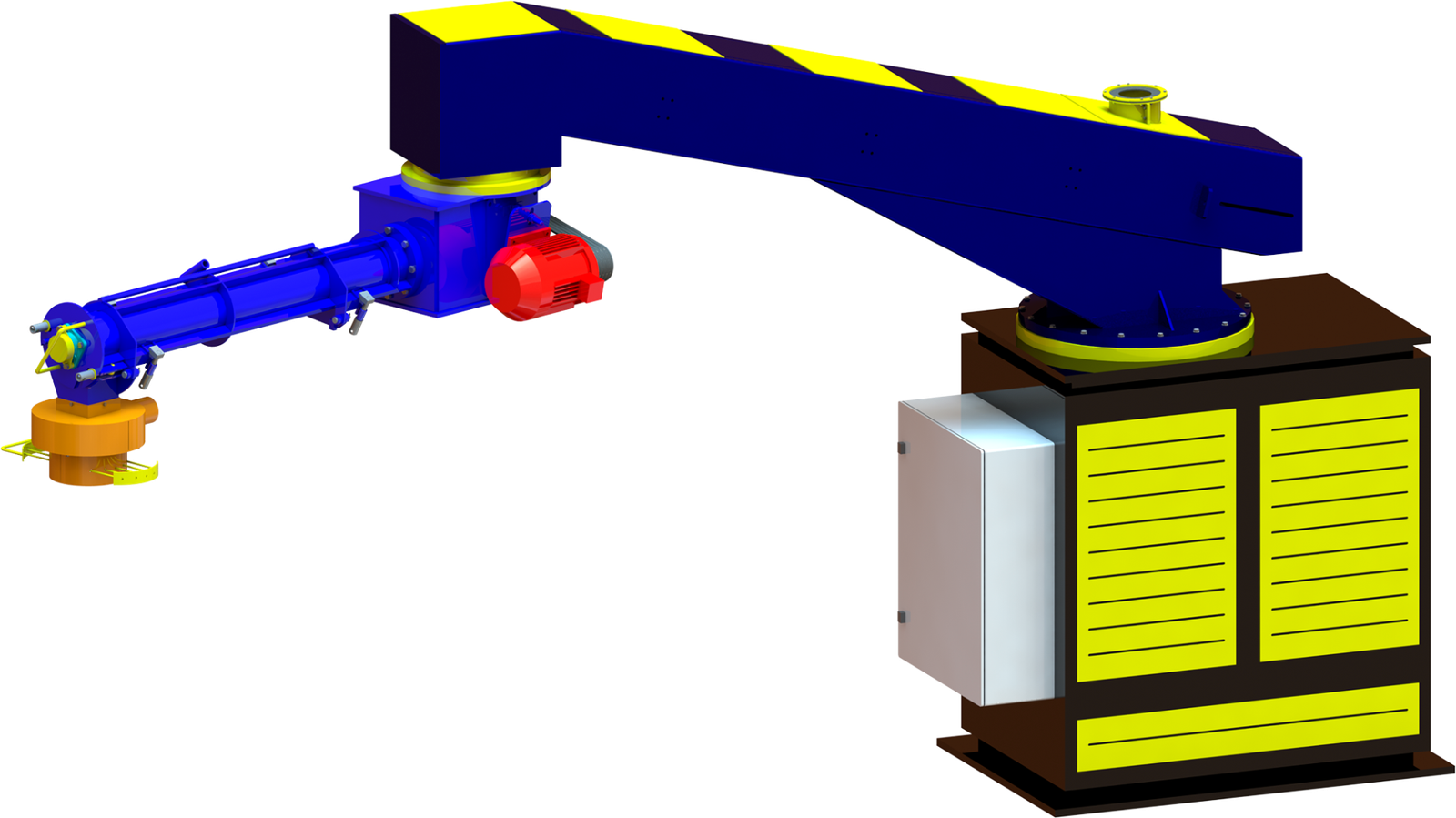

Piston Air Compressors

- How They Work: Use pistons to compress air into a tank.

- Applications: Affordable and effective for general sandblasting.

Single-Stage Compressors

- How They Work: Compress air directly into the tank in one stage.

- Applications: Light to medium-duty tasks; ideal for small-scale use.

Two-Stage Compressors

- How They Work: Compress air in two stages for higher pressure.

- Applications: Best for heavy-duty and industrial sandblasting.

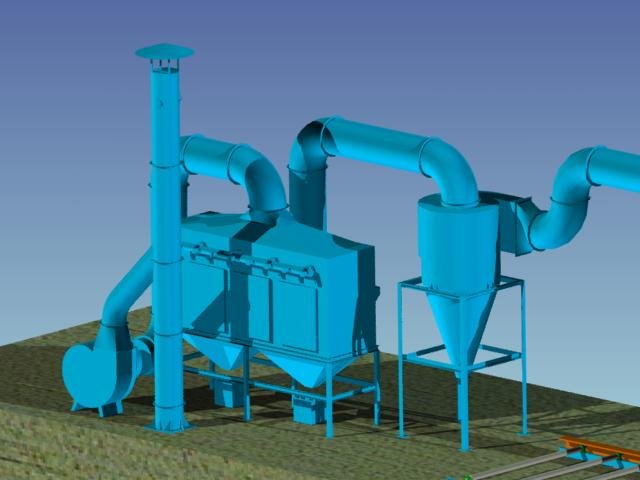

Rotary Screw Compressors

- How They Work: Use two rotating screws to compress air.

- Applications: High-volume output for large-scale applications.

Vertical Screw Compressors

- How They Work: Space-saving rotary screw design with vertical orientation.

-

Applications: Common in industrial setups with limited floor space. Compressor Type Best For Piston Affordable, general sandblasting. Single-Stage Light to medium-duty tasks. Two-Stage Heavy-duty and industrial applications. Rotary Screw Large-scale, high-volume tasks. Vertical Screw Industrial setups with space constraints.

Additional Factors to Consider

Tank Size

A larger tank allows for longer operation without frequent cycling, ensuring consistent pressure during sandblasting.

Duty Cycle

Choose compressors with a high-duty cycle to withstand prolonged use in demanding conditions.

Noise Level

For indoor or workshop use, quieter compressors reduce noise pollution and enhance operator comfort.

Portability

Portable compressors are ideal for smaller, on-site tasks requiring mobility.

| Factor | Why It’s Important |

|---|---|

| Tank Size | Reduces cycling frequency. |

| Duty Cycle | Handles prolonged use. |

| Noise Level | Suitable for indoor applications. |

| Portability | Convenient for mobile tasks. |

Tips for Maximizing Air Compressor Efficiency

- Ensure Tight Connections: Check hoses and fittings to prevent air leaks.

- Regular Maintenance: Clean filters and perform routine checks to avoid downtime.

- Match Abrasive and Equipment: Use abrasives that complement your compressor and sandblaster type.

| Efficiency Tip | Benefit |

|---|---|

| Tight Connections | Prevents pressure loss. |

| Regular Maintenance | Reduces breakdowns and downtime. |

| Proper Matching | Enhances performance and results. |

Conclusion: Choose the Right Air Compressor for Optimal Sandblasting Performance

Selecting the right size air compressor is critical for achieving consistent, efficient sandblasting results. By understanding the roles of CFM and PSI, identifying suitable compressor types, and considering additional factors like tank size and portability, you can optimize your sandblasting workflow.

Investing in the right air compressor ensures better results, reduced costs, and improved productivity for any project.