Foundries play a crucial role in the production of metal parts, providing the foundation for many industries such as automotive, aerospace, and construction. But what exactly does a foundry do, and what kind of equipment is required to run such an operation?

Foundry equipment encompasses the machinery and tools needed for metal casting. From melting furnaces to molding machines, these systems are essential for shaping metals into usable components, vital for industries like automotive and construction.

If you've ever driven a car or used a piece of machinery, you've likely interacted with components made in a foundry. Let’s take a deep dive into what makes up the foundry process and its necessary equipment.

What is a Foundry?

At its core, a foundry is a facility where metal castings are produced by melting metal and pouring it into molds to create specific shapes. Foundries are central to manufacturing because they produce parts used across various industries, including automotive, aerospace, machinery, and infrastructure.

A foundry transforms raw metal into usable components by utilizing heat, molds, and various specialized equipment to produce durable, high-quality metal parts. These castings are integral to everything from engine blocks to railway tracks.

Foundries are indispensable for modern manufacturing, playing an essential role in producing components for industries like:

- Automotive: Engine blocks, wheels, and transmission cases.

- Aerospace: Parts such as turbine blades and structural components.

- Construction: Steel beams, fittings, and other infrastructure components.

The process of creating these parts is complex, requiring a variety of equipment for different stages.

Foundry Process Overview

The metal casting process in a foundry is typically broken down into several key steps, each requiring specific equipment. Here’s a quick look at the steps involved in casting metal parts:

- Patternmaking: Creating a replica of the desired casting.

- Molding: Preparing molds for pouring metal.

- Melting: Heating metal to its molten state.

- Pouring: Transferring molten metal into molds.

- Ejection and Cooling: Solidifying and removing the cast.

- Cleaning and Fettling: Removing excess material and finishing the product.

- Inspection: Quality control and ensuring standards are met.

Foundry Equipment and Machinery

Now that we understand the process, let's take a look at the key equipment required in a foundry:

Melting Furnaces: Types and Uses

- Electric Arc Furnace (EAF): Uses electrical arcs to melt scrap metal, widely used in steel production.

- Induction Furnace: Uses electromagnetic induction to heat metal, ideal for small batches and non-ferrous metals.

Ladles and Forklifts: Transporting Molten Metal

- Ladles are used to transfer molten metal from the furnace to the molds.

- Forklifts help move heavy equipment and materials around the foundry.

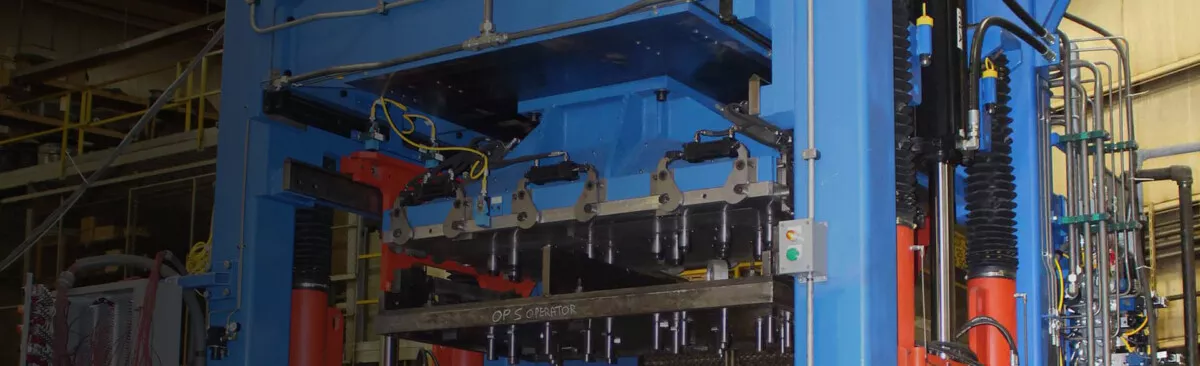

Molding Machines: Machinery Used in Molding and Pattern Making

- These machines create the molds that will hold the molten metal. They range from manual presses to fully automated systems.

Cranes and Conveyors: Moving Materials and Castings

- Foundries rely on cranes and conveyors to move heavy raw materials, molds, and finished castings throughout the facility.

Specialized Equipment for Different Metals

Foundries work with both ferrous (iron and steel) and non-ferrous (aluminum, copper, etc.) metals, and each type requires specific equipment to ensure optimal performance.

- Ferrous Foundries: Specialize in iron and steel castings. The equipment used for these metals often includes larger furnaces and more robust casting systems.

- Non-Ferrous Foundries: Focus on metals like aluminum, brass, or copper. These foundries typically use induction furnaces and more delicate molding and cooling systems due to the lower melting points of non-ferrous metals.

Foundry Design & Safety Considerations

Working in a foundry is inherently dangerous due to the high temperatures and the handling of molten metal. Thus, safety is a top priority.

Hazards in Foundries:

- Extreme Temperatures: Molten metal can reach temperatures exceeding 1500°C, posing severe risks to workers.

- Steam Explosions: Water can cause explosions if it comes into contact with molten metal.

Safety Measures:

- Protective Gear: Workers are required to wear heat-resistant clothing, gloves, and face shields to protect themselves from the intense heat.

- Fire Safety: Fireproof materials and extinguishers are essential in a foundry to prevent the spread of fires.

- Training: All employees must undergo rigorous safety training to handle molten metal and other hazardous materials properly.

Industries That Rely on Foundries

Foundries supply components to many key industries, providing the raw material for products used in everyday life.

Key Industries Using Metal Castings:

- Automotive: Engine blocks, wheels, and transmission parts.

- Aerospace: Turbine blades, engine components, and landing gear.

- Railroad: Train wheels, tracks, and components.

- Construction & Heavy Equipment: Structural parts, machinery components.

Global Demand for Foundry Products:

Foundries operate on a global scale, supplying metal castings to a variety of industries around the world. With the rise of emerging markets and continued industrialization, foundries are increasingly meeting the demand for high-quality castings across different regions.

Foundry Trends and Innovations

The foundry industry is constantly evolving with new technologies and operational trends.

Recent Trends in Foundry Operations:

- Automation: The role of automation in foundries continues to grow. Robots are now used for tasks like pouring molten metal, cleaning castings, and even handling quality control.

- On-site Finishing: A trend towards completing parts entirely within the foundry—reducing costs and ensuring quality consistency.

Advanced Furnace Technologies:

Innovations in furnace technology aim to make the melting process more energy-efficient, safer, and environmentally friendly. Newer furnaces have improved temperature control and reduce energy consumption.The Impact of Raw Material Costs and Automation:

The cost of raw materials, especially metals, is rising. Automation and advancements in furnace technologies help foundries reduce labor costs and improve material efficiency.

Conclusion

Foundries are vital to modern manufacturing, producing components for industries that touch every part of our daily lives. From melting and pouring metal to intricate finishing processes, foundry equipment plays a central role in ensuring high-quality, durable products.

As technology advances, foundries are adopting automation, improving safety standards, and finding new ways to reduce costs, ensuring they remain competitive in a global marketplace.