If you’re still relying on manual mixing for resin sand, you’re likely sacrificing consistency and performance in your castings.

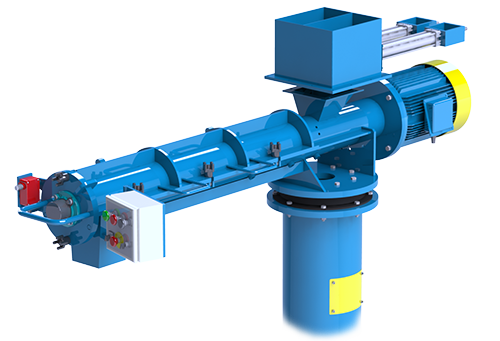

A resin sand mixer is a specialized machine that combines silica sand, resin, and hardener to create uniform, chemically bonded sand molds—crucial for producing high-quality, dimensionally accurate castings.

This article outlines what a resin sand mixer is, how it works, its benefits, and how to select the right one for your foundry operations.

What Is a Resin Sand Mixer?

Using resin-based molds without a mixer? You're risking quality at every pour.

A resin sand mixer blends silica sand with chemical resins and hardeners, producing strong, mold-ready sand for precision casting.

Dive deeper

In chemically bonded sand systems like furan and phenolic resin casting, mold quality directly depends on how evenly the resin is distributed. A resin sand mixer ensures this uniformity by blending components mechanically, achieving a homogenous mix with optimal binder activation.

I’ve implemented these machines across various foundries, from valve producers to heavy steel component makers. Every time, the mixer proved pivotal in improving casting surface finish and dimensional reliability.

How Does a Resin Sand Mixer Work?

Manual mixing can’t achieve the level of consistency required for today’s casting demands.

A resin sand mixer receives pre-measured silica sand, resin, and catalyst, then agitates the mixture at high speed, producing uniformly coated sand suitable for immediate molding.

Dive deeper

The resin sand mixing process includes:

- Feeding dry silica sand into the hopper

- Automatic dosing of resin and hardener (typically furan or phenolic)

- High-speed agitation in a continuous or batch-style chamber

- Output of mold-ready resin sand

| Type | Ideal For | Output Format |

|---|---|---|

| Continuous Mixer | Large-scale, automated lines | Steady sand discharge |

| Batch Mixer | Small or varied jobs | Controlled batch output |

Continuous mixers are often integrated with automatic molding systems, feeding directly into core shooters or flask filling stations. Batch mixers, by contrast, allow precise control for specialized or small-run castings.

Types of Resin Sand Mixers

Choosing the wrong mixer type can bottleneck your entire production line.

There are two primary types: batch mixers for small-scale or flexible operations, and continuous mixers for high-volume, automated foundry lines.

Dive deeper

1. Batch Resin Sand Mixer

- Capacity: typically 10–100 kg per cycle

- Ideal for: jobbing foundries, custom casting

- Features: manual control, compact design

- Pros: flexibility, lower cost

- Cons: not suited for mass production

2. Continuous Resin Sand Mixer

- Capacity: 1–30 tons/hour

- Ideal for: automotive and industrial foundries

- Features: automatic dosing, PLC control, high-output

- Pros: consistency, automation-ready

- Cons: higher initial investment

| Feature | Batch Mixer | Continuous Mixer |

|---|---|---|

| Production Scale | Low–Medium | Medium–High |

| Automation | Manual/Semi-auto | Fully automated |

| Cost | Lower | Higher |

| Space Requirement | Small footprint | Larger system layout |

Key Benefits of Using a Resin Sand Mixer

Still mixing by hand or using basic tools? You're losing time, money, and precision.

A resin sand mixer improves mixing uniformity, casting surface quality, and production speed while reducing material waste and operational inconsistencies.

Dive deeper

From practical experience, these benefits are not just theoretical—they deliver measurable improvements:

| Benefit | Description |

|---|---|

| Uniform Resin Coating | Stronger molds, reduced gas-related defects |

| Improved Surface Finish | Minimizes post-machining costs |

| Controlled Binder Use | Lowers chemical costs and waste |

| High Throughput | Some models exceed 10 tons/hour |

| Repeatability | Critical for multi-shift operations |

One client, producing turbine housing components, cut resin usage by 20% after switching to a PLC-controlled continuous resin mixer. That translated to substantial annual savings and better casting repeatability.

Applications of Resin Sand Mixers in Foundries

Precision applications need precision molds—and that starts with the right mixer.

Resin sand mixers are used for mold and core preparation in industries requiring high strength, dimensional accuracy, and surface finish, such as automotive, aerospace, and heavy machinery.

Dive deeper

Industries that commonly use resin sand mixers:

- Automotive: gearboxes, crankcases, structural brackets

- Aerospace: impellers, housings, precision valve bodies

- Machinery: large pump casings, turbine supports

- Energy: wind power housings, gas turbine parts

They’re compatible with multiple metals, including:

| Metal Type | Typical Use |

|---|---|

| Cast Iron | Large housings, valve bodies |

| Steel | Structural, wear-resistant parts |

| Aluminum | Lightweight high-precision components |

| Bronze & Brass | Corrosion-resistant fittings |

Resin Sand Mixer vs Green Sand Mixer

Not sure which mixing system your foundry needs?

Resin sand mixers are used for chemically bonded sand systems with higher strength and precision; green sand mixers are used for clay-bonded, high-speed production.

Dive deeper

| Feature | Resin Sand Mixer | Green Sand Mixer |

|---|---|---|

| Binder | Furan/Phenolic | Bentonite Clay |

| Mold Strength | High | Moderate |

| Surface Finish | Excellent | Moderate |

| Reusability | Limited | High |

| VOC Control Needed | Yes | Lower |

| Application | Precision castings | Mass production |

Resin sand systems shine in applications where dimensional accuracy and strength matter more than speed. Green sand is better for fast-turnaround, low-cost production.

Factors to Consider When Choosing a Resin Sand Mixer

Overlooking a key factor now can cost thousands later.

Key considerations include production scale, resin type, mold size, space, and maintenance support.

Dive deeper

| Factor | What to Evaluate |

|---|---|

| Production Volume | Daily output (tons/hour or molds/day) |

| Resin System | Furan, phenolic, alkaline phenolic—check machine compatibility |

| Mold Complexity | Higher complexity may need finer resin control |

| Facility Layout | Check space, flow direction, integration needs |

| Maintenance | Ease of cleaning, part availability, blade inspection access |

One mistake I’ve seen is choosing a high-capacity mixer without assessing resin curing time. If mold line speed doesn’t match, you risk material hardening mid-flow—causing scrap and costly downtime.

Maintenance Tips for Resin Sand Mixing Machines

A well-maintained mixer is the backbone of mold consistency.

Routine maintenance prevents resin buildup, component wear, and performance drops. Establish a schedule and stick to it.

Dive deeper

Recommended checklist:

| Task | Frequency |

|---|---|

| Clean resin nozzle and sand feed port | Daily |

| Inspect paddles or blades for wear | Weekly |

| Check dosing calibration | Weekly |

| Clear hardened resin from chamber | As needed |

| Lubricate moving parts | Monthly |

| Replace worn seals and gaskets | Quarterly |

Failing to clean resin deposits can lead to clogged chutes, inconsistent mixing, and unplanned downtime—issues I’ve encountered in several under-maintained facilities.

Environmental Considerations and Safety

Ignoring safety and emissions can cost more than just money.

Resin systems emit fumes and VOCs during mixing. Proper ventilation, dust control, and safe handling procedures are essential.

Dive deeper

To stay compliant and protect workers:

- Install localized exhaust systems at mixing stations

- Use enclosed mixers with dust hoods

- Employ filters for VOC scrubbing

- Provide PPE (gloves, masks, goggles) for operators

- Use PLC systems to limit resin exposure time

Environmental standards are tightening across global markets. Ensuring your mixer supports sustainable operation is no longer optional—it's a competitive necessity.

FAQs About Resin Sand Mixers

Q: What’s the best resin type for general-purpose castings?

A: Furan resin is widely used due to strong bonding and moderate cost.

Q: How long is resin-coated sand usable after mixing?

A: Typically 5–30 minutes, depending on hardener ratio and temperature.

Q: Are compact or mobile mixers available?

A: Yes, several manufacturers offer mobile batch mixers for small foundries or job sites.

Q: Can the mixer be integrated into a core-making line?

A: Absolutely. Continuous mixers are often connected directly to core shooters and molders.

Conclusion

Resin sand mixers are essential equipment for modern foundries aiming for high-precision, chemically bonded molds. The right mixer can elevate your casting quality, reduce costs, and improve consistency. Always align your choice with production needs, material types, and long-term maintenance capability. Consulting with an experienced equipment supplier is the first step toward making the right investment.