From the cars we drive to the machines that build our homes, most things around us started their life in a foundry.

A foundry is a specialized factory where metal is melted and poured into molds to create parts of all shapes and sizes. These castings form the foundation of modern manufacturing.

If you’ve ever wondered how raw metal becomes an engine block or a turbine housing, this article will walk you through the essentials of how a foundry works, the processes it uses, the equipment it relies on, and the trends shaping its future.

Foundry Definition: The Basics?

Metal parts don’t appear out of thin air—they are shaped, poured, cooled, and refined in foundries.

A foundry is a factory where metal is melted and poured into molds to make cast parts used in cars, trains, machines, and consumer products.

Definition:A foundry is an industrial facility where metal casting takes place. The core function is to melt raw metal and pour it into molds that form parts used across industries.

Scope of Application:

- Automotive: Engine blocks, brackets, transmission housings

- Rail: Wheels, couplers, brake shoes

- Construction: Pipes, valve bodies, heavy structural components

- Consumer Manufacturing: Stove parts, washing machine components

Industrial Role:Roughly 90% of manufactured goods use cast metal parts—making foundries a cornerstone of the global supply chain.

The Metal Casting Process: Step-by-Step?

Casting might look simple, but it involves multiple precise steps to ensure part quality and safety.

From pattern making to final inspection, the casting process transforms metal into durable, engineered components.

Patternmaking:

- Create a model of the final part using wood, plastic, or metal.

- This pattern is used to shape the mold cavity.

Molding:

- Sand (usually silica-based) is packed around the pattern to form the cavity.

- Advanced molds may include cores to create internal features.

Melting & Pouring:

- Metal is melted above its melting point in furnaces (e.g., electric arc furnace, induction furnace).

- Molten metal is transferred using ladles and poured carefully into the prepared molds.

Cooling & Solidification:

- The casting is left to cool and solidify inside the mold.

- Cooling rates are controlled to ensure structural integrity.

Fettling & Cleaning:

- Remove the mold material and clean the casting.

- Grinding, blasting, and trimming refine the part.

- Quality control ensures dimensional accuracy and defect-free results.

| Step | Description |

|---|---|

| Patternmaking | Build a shape replica of the part |

| Molding | Pack sand to form mold cavity around pattern |

| Melting & Pouring | Heat metal and transfer molten material to mold |

| Cooling | Allow metal to solidify in a controlled environment |

| Fettling & Cleaning | Remove mold material, finish the casting, and inspect quality |

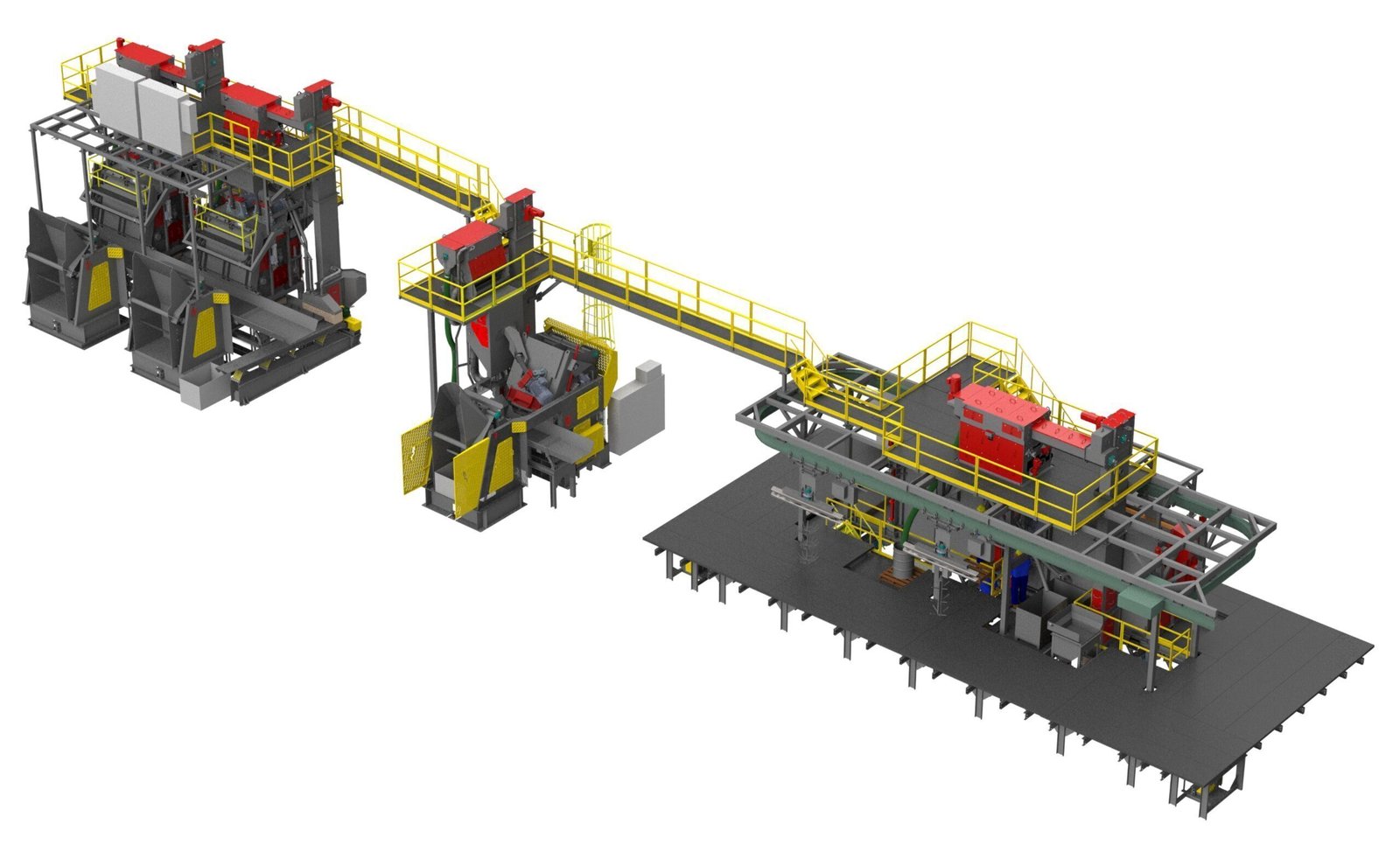

Foundry Equipment Overview?

Foundries rely on a wide range of tools and machines to melt metal, form molds, and refine finished parts.

Furnaces, molding systems, and lifting cranes all play critical roles in producing cast components.

Furnaces:

- Electric Arc Furnace: Common for steel.

- Induction Furnace: Ideal for precise temperature control (used for copper, aluminum).

- Cupola Furnace: Traditional choice for cast iron.

Pouring Tools:

- Ladles: Transfer molten metal to molds.

- Pouring Devices: Ensure smooth, controlled metal flow.

Molding and Core-Making Machines:

- Molding Machines: Automatically compress sand around the pattern.

- Core Shooters: Create cores for internal cavities.

- CNC Pattern Makers: Used for high-precision pattern fabrication.

Material Handling:

- Overhead Cranes: Transport large ladles and castings.

- Roller Conveyors: Move molds or cast parts along the production line.

| Equipment Type | Examples |

|---|---|

| Furnace | Electric arc, induction, cupola |

| Molding Machinery | Sand mixers, jolt-squeeze molding |

| Handling Tools | Cranes, conveyors |

| Finishing Equipment | Grinders, sandblasters, cleaning booths |

Foundry Design & Safety Management?

With molten metal temperatures exceeding 2600°F, safety isn’t optional—it’s a top design priority.

Proper foundry design and strict safety protocols prevent steam explosions, fire hazards, and operator injuries.

Why Foundries Are Dangerous:

- High temperatures present burn and fire risks.

- Water contact with molten metal causes steam explosions.

- Charging (adding metal to the furnace) is one of the most dangerous steps.

Key Safety Design Considerations:

- Tall, ventilated roofs to allow heat escape.

- Fireproof floors made of compacted dirt or refractory concrete.

- Dedicated, isolated pouring zones to reduce accident risks.

- Clearly marked pedestrian and machine routes.

Personal Protective Equipment (PPE):

- Heat-resistant clothing

- Face shields and goggles

- Respirators in areas with fumes

- Ear protection in high-noise environments

| Safety Element | Function |

|---|---|

| Ventilation | Controls heat and smoke in working zones |

| Heat-Resistant Floors | Prevents fire hazards from molten metal spillage |

| PPE Requirements | Protects workers from burns, fumes, and flying debris |

Foundries Beyond Casting: Value-Added Services?

Today’s foundries don’t just pour metal—they offer full-service manufacturing solutions.

Modern foundries provide design, machining, and assembly services to deliver ready-to-use components.

Part Design:Collaborate with engineers to optimize castability and reduce material waste.

Tooling and Mold Making:Design and manufacture custom molds, patterns, and cores.

Rapid Prototyping:Use 3D printing and CNC to develop and test part designs quickly.

Machining and Assembly:Deliver near-net or fully finished parts with machining, boring, or assembly.

Technical Support & Aftermarket Service:Assist customers with product installation, performance optimization, and defect troubleshooting.

Trends in the Global Casting Industry?

The global casting industry is rapidly evolving—especially as labor costs rise and automation becomes essential.

China leads in output, but global trends are pushing toward automation, integration, and smart foundries.

Global Output:

- China produces over 44.5 million tons of castings annually.

- The U.S. remains second in production value despite fewer foundries.

- India, Germany, and Japan are also major players.

Industrial Shifts:

- Large foundries are replacing small workshops through mergers.

- Automatic molding lines and robotics are now standard in high-volume plants.

- Foundries are integrating services: machining, cleaning, even packaging.

Persistent Challenges:

- Material costs may decline, but labor and compliance costs are rising.

- Finding skilled operators is harder, especially for hazardous tasks.

- Balancing efficiency, safety, and environmental compliance drives tech innovation.

| Region | Casting Output (tons/year) | Notable Trends |

|---|---|---|

| China | 44.5 million | Scale, automation, export-driven |

| United States | ~11 million | High value-added casting, consolidation |

| Europe | ~10 million | Energy cost pressure, quality focus |

Conclusion: The Foundry’s Role in Modern Industry

Foundries are the invisible foundation of modern manufacturing. By shaping raw metal into critical components, they enable industries to build, move, and grow. As foundries become safer, smarter, and more connected, they’ll continue playing a vital role in the world’s industrial future.