Are you still making sand cores manually, struggling with inconsistency and high labor costs?

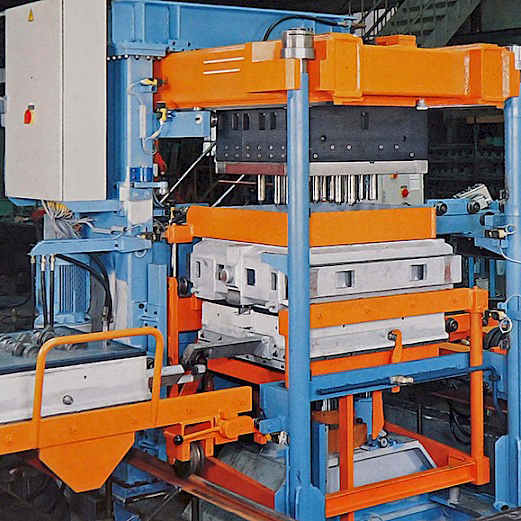

A core shooter machine is a foundry device used to create sand cores by injecting a sand-binder mixture into a core box under high pressure, ensuring precision and uniformity.

Modern foundries rely on core shooter machines to produce high-quality cores with efficiency, consistency, and minimal waste. Let's explore why these machines are indispensable in precision casting.

What Is a Core Shooter Machine?

Manual core making often leads to defects, dimensional errors, and inconsistent production quality.

A core shooter machine automates the sand core production process by shooting resin-coated sand into a core box to form the desired shape with high accuracy.

These machines are used in foundries to create sand cores that define the internal cavities of metal castings. Their main purpose is to ensure consistent core geometry, especially for complex and high-performance castings.

The significance of core shooter machines lies in their ability to automate and streamline one of the most critical parts of the casting process. Cores made using these machines show better surface finish, dimensional tolerance, and strength compared to traditional manual cores.

In my experience, automating core making was a turning point—it helped us eliminate 80% of casting defects due to core shifting and poor compaction.

How Does a Core Shooter Machine Work?

Manually packing sand into a mold is slow and often leads to uneven compaction.

The core shooter machine uses compressed air to fill the core box with sand, compacts it under pressure, and then cures it using a chemical or heat-based binder system.

The typical steps are:

- Sand Loading – Sand mixed with a chemical binder is fed into the hopper.

- Shooting – The shooting head injects sand into the core box using compressed air.

- Compaction – Pressure ensures dense, uniform filling.

- Curing – Depending on the process, curing happens via heat, gas, or ambient conditions.

- Core Ejection – The finished core is ejected and collected.

Different machines may use different curing systems, such as:

| Curing Method | Description | Suitable Application |

|---|---|---|

| Cold Box | Amine gas cures the binder at room temperature | Automotive precision cores |

| Hot Box | Uses heated core boxes to cure thermosetting resin | Heavy-duty industrial casting |

| Shell Core | Heats sand partially to form a shell, then dumps excess | Hollow, thin-walled cores |

Each of these methods fits specific production needs, and we often help clients select based on their alloy types and casting complexity.

Types of Core Shooter Machines

Using the wrong machine type can severely limit production speed and product quality.

Core shooter machines come in horizontal and vertical types, and can be operated manually or automatically depending on production volume and budget.

Here’s how to differentiate:

| Machine Type | Description | Best For |

|---|---|---|

| Horizontal Core Shooter | Horizontal clamping and shooting axis | Long cores and complex shapes |

| Vertical Core Shooter | Vertical shooting, compact footprint | Small or medium-sized cores |

| Manual Machine | Operator-controlled | Low-volume, custom jobs |

| Automatic Machine | PLC-controlled, robotic ejection | Mass production |

From my 20 years in the industry, I always advise clients to balance machine size and automation with their batch size and core complexity. Don’t overspend on a fully automated line if your production demand is seasonal or variable.

Main Components of a Core Shooter Machine

Unexpected machine downtime usually stems from poor understanding of its components.

A typical core shooter includes a sand hopper, shooting head, core box, clamping system, and a programmable control unit for automation.

Here’s a breakdown:

| Component | Function |

|---|---|

| Sand Hopper | Stores and feeds mixed sand into the system |

| Shooting Head | Uses air pressure to inject sand into the core box |

| Air Venting System | Allows trapped air to escape for full cavity filling |

| Core Box | The mold that shapes the sand into a core |

| Clamping System | Holds the core box securely during shooting |

| Control Panel | Enables automated sequences and monitoring |

I’ve seen many production lines grind to a halt due to a clogged vent system or misaligned clamping. Regular inspections and a deep understanding of these components can avoid expensive downtime.

Applications of Core Shooter Machines in Foundries

Certain industries require internal geometries that are impossible to achieve manually.

Core shooter machines are widely used in automotive, aerospace, and heavy machinery casting where complex internal cavities are essential.

Some typical applications include:

- Automotive: Cylinder heads, intake manifolds, engine blocks

- Aerospace: Lightweight housing with complex air channels

- Pumps/Valves: Intricate flow paths needing strong and thin-walled cores

- General Foundry: Any part requiring internal hollowing or specific voids

In our projects, core shooter machines consistently reduced rejection rates and allowed the creation of cores that were previously considered too complex or costly.

Benefits of Using a Core Shooter Machine

Manual core making leads to inconsistent quality, especially as demand scales up.

Using a core shooter machine increases speed, precision, and consistency while reducing labor costs and material waste.

Here’s a clear comparison:

| Advantage | Explanation |

|---|---|

| Speed | Cores produced in seconds vs minutes manually |

| Precision | High dimensional accuracy reduces downstream defects |

| Consistency | Automated shooting and curing ensure uniform quality |

| Automation Ready | Can be integrated into full production lines |

When we upgraded a client’s foundry with core shooter automation, their production speed doubled within the first month—without adding a single new worker.

How to Choose the Right Core Shooter Machine

Buying the wrong core shooter machine can waste both time and capital.

The right core shooter machine depends on your core shape complexity, production volume, factory space, and budget.

Key factors to consider:

- Production Volume: Large batches benefit from automated models.

- Core Size & Complexity: Vertical machines for simple, horizontal for complex.

- Machine Footprint: Limited space? Go for compact vertical models.

- Customization: Some models allow interchangeable core boxes.

- Budget & ROI: Evaluate long-term savings in labor and quality improvements.

In a recent consultation, I helped a mid-size foundry choose a semi-automatic vertical core shooter with dual stations—it paid for itself in under 9 months due to reduced defects.

Maintenance and Safety Tips for Core Shooter Machines

Ignoring preventive maintenance often leads to costly machine failure and downtime.

Routine maintenance and safety checks ensure reliable operation, extended machine life, and operator protection.

My personal checklist includes:

- Clean Sand Hopper Weekly – Prevents clogging and inconsistent feed.

- Check Venting Systems – Ensures proper sand compaction.

- Align Core Box Regularly – Misalignment causes flashing and defects.

- Inspect Air Pressure Valves – Pressure drop affects core density.

- Use Safety Shields and Emergency Stops – Operator safety must come first.

Also, don’t forget to schedule a full system inspection every 3-6 months. We offer a service package to clients that includes calibration, alignment, and software diagnostics.

Core Shooter Machine vs Traditional Core Making Methods

Sticking to manual core making in a competitive industry is a losing game.

Compared to traditional methods, core shooter machines offer superior efficiency, repeatability, and lower labor dependency.

Here’s a comparison table:

| Criteria | Manual Core Making | Core Shooter Machine |

|---|---|---|

| Labor Need | High | Low |

| Cycle Time | 5–10 min/core | <1 min/core |

| Defect Rate | High | Low |

| Scalability | Difficult | Easy with automation |

| Core Quality | Inconsistent | Uniform |

We once helped a traditional foundry reduce their core making team from 12 to 4 operators, reallocating labor to more skilled positions and improving morale.

Conclusion: The Role of Core Shooter Machines in Modern Foundry Technology

Core shooter machines are essential for producing consistent, precise sand cores required in high-performance castings. Their adoption leads to faster cycles, better quality, and reduced waste. Investing in the right system will future-proof your foundry and keep you ahead in a competitive market.