Choosing the wrong resin sand molding & recycling line can cripple your casting quality and drive up maintenance costs.

Avoid these 7 common mistakes when selecting a resin sand molding line to ensure stable performance, low dust, and long-term reliability.

I’ve spent over two decades helping foundries around the world design and optimize their resin sand systems. These aren't theoretical issues—they’re problems I’ve personally seen, diagnosed, and solved in the field.

Mistake 1: Ignoring Sand Flow Layout

A poorly designed sand return system is a silent productivity killer—it clogs ducts, wears out motors, and spreads dust.

Use looped layouts, gravity chutes, and sealed conveyors to avoid blockages and reduce dust.

One customer I worked with in Eastern Europe had constant wear in their return elevators and transfer elbows. The issue? Their layout used too many sharp turns and horizontal conveyors. We redesigned the loop to use more vertical drops and fewer transitions—and their maintenance costs dropped by 30% within three months.

A proper layout includes:

- Closed-loop return path

- Covered belt conveyors

- Gravity-fed sand drops

- Separated reclaimed/fresh sand flow

If your supplier won’t show you a full system flowchart or simulation, find one who will.

Mistake 2: Over-Specifying the Sand Cooler

Coolers that are too large aren’t just more expensive—they can ruin the sand’s moisture balance and mixing quality.

Select your cooler based on actual throughput, not peak assumptions. Oversizing leads to energy waste and poor resin mixing.

I remember a customer in South China who bought a cooler rated for 25 TPH—when their actual reclaim was 10 TPH. They ended up over-drying their sand and losing resin bonding strength. When we installed a variable-speed cooler, their scrap rate dropped significantly.

Proper Cooler Selection

| Line Capacity (TPH) | Recommended Cooler Type | Features |

|---|---|---|

| 5–10 | Drum-type fixed speed | Stable, low maintenance |

| 10–20 | Variable-speed or fluidized | Adapts to load, consistent output |

| 20+ | High-efficiency fluidized bed | Higher energy efficiency |

The cooler is not just a heat exchanger—it's part of your mold quality control.

Mistake 3: Not Testing Binder Compatibility

Each resin has its own quirks. Assuming compatibility across mixers and reclaimers is a recipe for production delays.

Not all resins work with all mixers or reclaim systems. Always test your binder in real mixing conditions.

Years ago, a customer in Indonesia ordered a system optimized for furan resin, but later switched to a phenolic resin. The result? Shorter working times and blocked sand gates. We had to re-tune the reclaim system to reduce residual acid and adjust mixer speed.

Common Resin Matching

| Resin System | Recommended Mixer | Suitable Reclaimer |

|---|---|---|

| Furan | Single-arm, 35 rpm | Thermal + mechanical |

| Phenolic | Counterflow, slow blend | Mechanical only |

| PU-Cold Box | High-speed dual arm | Needs thermal pre-burnout |

Ask for test mixing and sample reclaim runs before you approve a full equipment order.

Mistake 4: Forgetting About Dust Control

Dust is more than a housekeeping problem. It causes lung hazards, sensor failures, and inspection penalties.

Install pulse-jet cartridge filters and measure outlet dust in real time to stay within safe limits.

One audit I conducted in Northern Europe revealed over 10 mg/m³ of ambient dust—double the legal threshold. The issue? Old-style bag filters and clogged ducts. We replaced them with pulse-cleaned cartridges and centralized dust collection. Within weeks, air quality and equipment reliability improved.

Key points:

- Use cartridge filters over bag filters

- Set alarms for differential pressure

- Ensure duct routing avoids sharp turns

- Clean filter banks regularly

A clean line is a productive and compliant line.

Mistake 5: Underestimating Maintenance Access

If your operators need to crawl or dismantle machines just to change a blade, you’re losing time and risking injury.

Leave 800–1000mm clearance around key equipment for routine checks and emergency repair.

In many compact designs, I see reclaimers crammed into corners, with no space to open access panels. It’s a mistake that delays response time during breakdowns. A smarter layout can pay back in uptime within the first year.

Maintenance Access Standards

| Equipment | Minimum Clearance (mm) | Purpose |

|---|---|---|

| Mixer drum | 1000 | Blade changes, liner checks |

| Elevator head | 800 | Chain tension, sprocket greasing |

| Dust collector | 1200 | Filter changes, pulse check |

Space costs less than lost production.

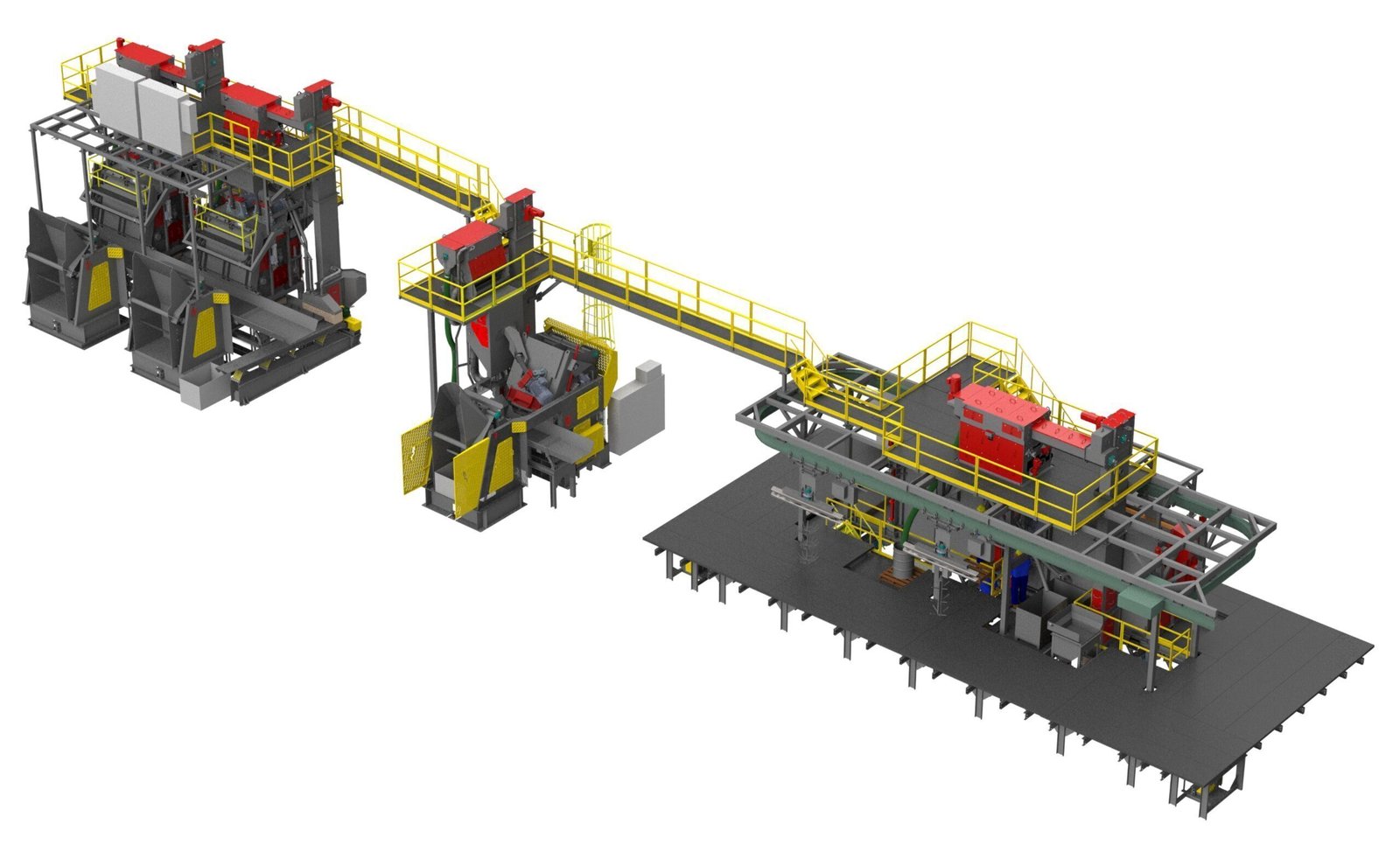

Mistake 6: Buying Without a Process Simulation

Every plant is different. What works for another foundry might choke your layout or overshoot your cycle time.

Ask for digital simulations of your layout, including sand flow, reclaim efficiency, and mixing sequence.

We once saved a customer six weeks of rework by simulating their entire plant in 3D before installation. The layout revealed a bottleneck at the sand return leg, which we fixed in advance. Without that check, it would have cost them tens of thousands in reengineering.

A complete simulation includes:

- Sand flow loop design

- Mixing cycle matching pattern size

- Heat load on cooler

- Reclaim loss tracking

No serious investment should be made without testing it on-screen first.

Mistake 7: Choosing Based on Price Alone

The lowest bidder often wins the order—but loses your trust six months later when parts are missing or service disappears.

Focus on total value—layout support, service team, local spares—not just the sticker price.

One customer of mine chose a cheaper European supplier over us. Within a year, they called me again—because the supplier had no engineers in Asia, and no replacement mixer arms in stock. They paid more in logistics and downtime than the upfront savings.

Cost vs Value Comparison

| Factor | Budget Supplier | Full-Service Partner |

|---|---|---|

| Design Consultation | ✖ | ✔ |

| On-site Commissioning | ✖ | ✔ |

| Spare Parts Readiness | ✖ | ✔ (stocked regionally) |

| Engineering Support | ✖ | ✔ (English/Chinese) |

Paying for reliability always costs less than recovering from failure.

Conclusion

Investing in a resin sand molding and recycling line isn’t just about machinery—it’s about long-term process stability. Avoid these 7 critical mistakes, and you’ll build a system that supports growth, quality, and compliance.

Need help reviewing your project design? We’re ready to support from concept to commissioning.