Your coating keeps peeling. Rejected shipments are climbing. And no matter how much you blast, rust keeps coming back.

If you’re still using a general-purpose shot blasting machine for steel pipes, you're not cleaning — you’re gambling. Pipe-specific machines exist for a reason.

You’re not alone. Many manufacturers use flat-bed or cabinet-style blasters, only to suffer from poor adhesion, hidden rust, and mounting rework costs. It doesn’t have to be this way.

The Pain No One Talks About — Why Standard Shot Blasting Fails for Steel Pipes

We’ve spoken to dozens of manufacturers. They all describe the same nightmare:

Rust reappears. Coatings fail. Pipes are rejected. Why? Because the blasting was never truly uniform.

| Pain Point | Consequence |

|---|---|

| Cylindrical shape not supported | Missed zones and uneven finishes |

| No interior cleaning capability | Rust trapped inside walls |

| Poor pipe rotation control | Inconsistent exposure to abrasives |

| High abrasive waste | Rising operational costs |

| Difficult loading & unloading | Downtime, alignment errors |

💬 “We spent more on recoating than on blasting itself — all because our machine wasn’t made for pipes.” — Pipe Coatings Manager, UAE

You’re not just losing money — you’re eroding trust with your customers.

Why Steel Pipes Require a Completely Different Approach

Pipes are not plates. They are complex, 3D cylinders — with a critical difference: their inner wall matters just as much as the outside.

Generic shot blasting machines were never meant to clean inside or fully wrap around pipes. Specialized equipment is the only way to guarantee 360° performance.

| Critical Challenge | Pipe-Specific Solution |

|---|---|

| Round shape creates shadow zones | Adjustable turbines for full-angle blasting |

| Interior rust hard to reach | Dedicated nozzles or air blast lances |

| Different diameters per order | Adjustable supports and auto-centering rollers |

| Long pipes = tough handling | Infeed/outfeed automation + alignment sensors |

Every pipe has a story. And your equipment must understand its language.

Side-by-Side Comparison: Standard Shot Blaster vs. Steel Pipe System

| Feature | General Shot Blaster | Steel Pipe Shot Blaster |

|---|---|---|

| Inner wall cleaning | ❌ Not supported | ✅ Direct access via nozzle |

| Pipe rotation during blasting | ❌ Static | ✅ Motorized & adjustable |

| Abrasive coverage | ❌ Flat, fixed angle | ✅ Tuned to pipe curvature |

| Size flexibility | ❌ Manual changeovers | ✅ Automatic adaptation |

| Surface consistency (Sa 2.5+) | ❌ Medium risk | ✅ High reliability |

Stop forcing a square machine into a round job.

How Pipe-Specific Shot Blasting Machines Solve All These Problems

These aren’t just tweaks — they’re a total redesign, purpose-built for your pipes.

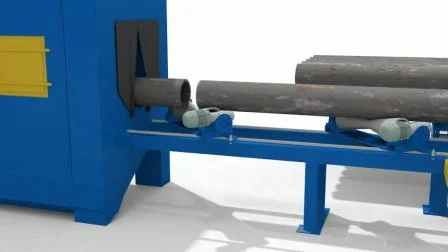

Pipe-specific shot blasting machines eliminate every problem you’ve been tolerating:

- ✅ Automatic pipe centering to prevent misalignment

- ✅ Rotating rollers that ensure full 360° exposure

- ✅ Customizable turbine angles to eliminate shadow zones

- ✅ Dedicated internal wall cleaning nozzles

- ✅ Abrasive recycling systems to lower media cost

- ✅ Supports wide diameter range without manual changeovers

- ✅ Modular integration with upstream/downstream systems

📌 Result? Better surface prep, stronger coatings, zero rework.

Real-World Transformation: From Rusty Rejections to Flawless Finish

Case Study – Major Steel Pipe Exporter (Middle East)

| Before Hitech-China Machine | After Implementation |

|---|---|

| 15% rejection rate | 0% rejections in 3 months |

| Manual loading + 3 operators | Automated feed, 1 operator |

| Missed interior cleaning | Dual-wall blast coverage |

| 6 pipes/hour throughput | 10+ pipes/hour |

💬 “The moment we installed the Hitech-China machine, the complaints disappeared — and so did the rust.”

Still Using a Generic Blaster? You’re Paying the Price

You may think your current machine “gets the job done.” But here’s what it’s really costing you:

| Hidden Cost | Real-World Impact |

|---|---|

| Media waste | 20–30% overuse = $10k/year lost |

| Failed coatings | Warranty claims, unhappy customers |

| Manual rework | $2,000/month average labor cost |

| Slower cycles | Delays, missed delivery deadlines |

💡 You’re not saving money — you’re leaking it.

How to Choose the Right Shot Blasting Machine for Pipes

Ask yourself these 5 critical questions before your next equipment investment:

- What’s your pipe diameter range?

- Do you need internal wall blasting?

- How many pipes per hour do you process?

- What’s your desired surface finish (e.g. Sa 2.5 or Sa 3)?

- Do you need automation, integration, or dust collection?

📞 Not sure? We’ll walk you through it. Every client gets a custom layout from our engineers.

Explore Hitech-China’s Pipe Shot Blasting Systems

We’ve been building pipe-focused blasting machines for over 20 years. Our systems are trusted by leaders in:

- ✅ Oil & Gas

- ✅ Shipbuilding

- ✅ Structural Steel

- ✅ Industrial Pipe Fabrication

| Model Name | Description |

|---|---|

| Inline Pipe Blaster | Fully automatic, high-throughput system |

| External Wall Blaster | Customizable for heavy-duty surface prep |

| Portable Pipe Unit | For on-site or mobile projects |

| Internal Wall Blasting System | Precision cleaning for pipe interiors |

All systems are engineered for easy integration, fast changeovers, and long life with wear-resistant parts.

Imagine This…

You walk into your plant.

- The pipes are rotating perfectly.

- Blasting is even, complete, and automated.

- No rust. No rework. No complaints.

- Operators are monitoring — not fixing.

- You deliver on time, every time.

This isn’t a dream. It’s your future with Hitech-China.

The Bottom Line: Not All Shot Blasting Machines Are Created Equal

You can’t clean a round pipe with a square solution.

Pipe-specific shot blasting machines are engineered for precision, efficiency, and peace of mind. The ROI starts from day one.

✅ Ready to stop rework and start winning?

Explore our pipe blasting machines

Or contact our engineers for a tailored recommendation.

FAQ

Can I use a regular blaster for steel pipes?

Technically, yes — but you'll struggle with incomplete cleaning, missed interiors, and failed coatings.

How do I blast the inside of a pipe?

Use a pipe-specific machine with internal air nozzles or rotating blast heads.

How long will a pipe-specific machine last?

10–15 years with proper maintenance, thanks to wear-resistant materials.

✅ Download Now

“5 Signs You’re Using the Wrong Shot Blaster for Pipes” – Free PDF Checklist