Trying to cut costs and boost sustainability in your foundry?

Here’s a full breakdown of the long-term cost differences between resin sand recycling and traditional sand disposal—backed by numbers and real-world savings.

Many foundry managers are surprised to learn how much money is lost in recurring disposal and raw material costs. If you’re deciding whether to recycle or toss your sand—this is for you.

1. The Hidden Costs of Traditional Sand Disposal

Think throwing used sand away is simpler?

Traditional disposal comes with recurring expenses and hidden liabilities that quietly eat into your profits.

At first glance, hauling away spent resin sand may seem easy. But when you dig deeper, the real costs begin to add up. These include:

- Continuous purchase of virgin resin sand

- Expensive waste disposal fees—especially in regions classifying it as hazardous

- Extra logistics and handling costs

- Environmental audit preparation and compliance fines

- Wasted materials that could be reused

💡 Did you know? Many foundries spend up to 30–40% of their surface treatment budget on new sand and disposal fees alone.

Here’s a breakdown of typical traditional disposal costs:

| Expense Type | Average Annual Cost (USD) |

|---|---|

| Virgin Sand Purchase | $80,000 – $150,000 |

| Waste Disposal | $15,000 – $40,000 |

| Labor for Manual Handling | $10,000 – $25,000 |

| Environmental Compliance | $5,000 – $20,000 |

| Total Estimate | $110,000 – $235,000 |

2. Upfront Cost of Resin Sand Recycling Systems

Worried about high initial investment?

Yes, recycling systems require upfront capital—but they’re designed to pay for themselves quickly through massive long-term savings.

The initial cost includes:

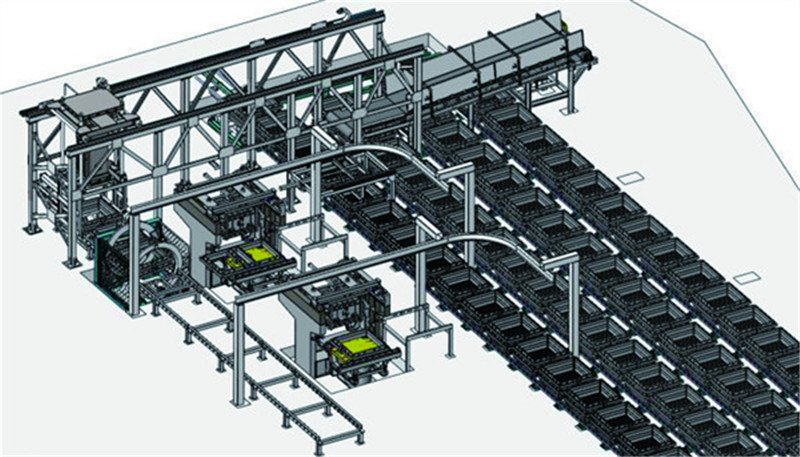

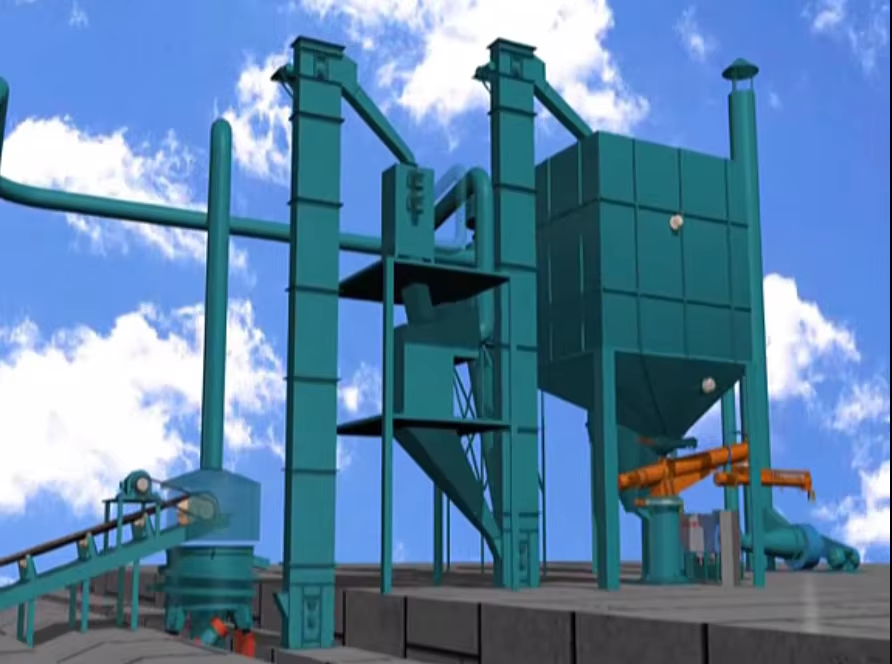

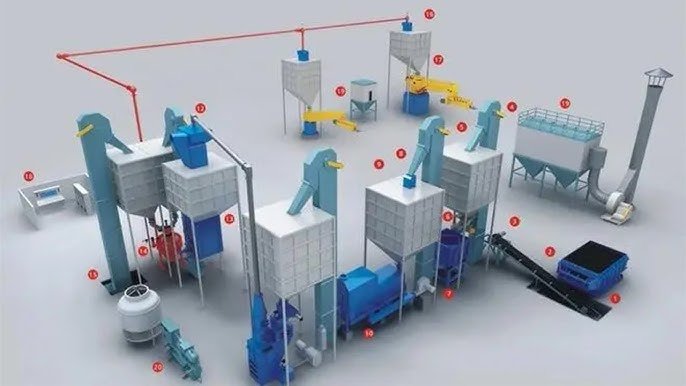

- Core equipment (crusher, sieving unit, magnetic separator, cooling)

- Automation (PLC controls, auto-feed conveyors, dust collectors)

- Installation, commissioning, and employee training

- Annual maintenance and spare parts

Typical investment ranges from $100,000 to $400,000, depending on system size and automation level. While this might seem steep, it's a one-time cost versus ongoing disposal expenses.

Here’s what you’re paying for:

| Component | Cost Impact |

|---|---|

| Base Equipment | $$$ |

| PLC and Automation | $$ |

| Dust Collection | $$ |

| Installation & Training | $ |

| Spare Parts (Annual) | $ |

💡 Think of this as buying a machine that makes your operations cheaper every single day.

3. Operational Savings from Sand Recycling

What’s the real benefit once the system is running?

Recycling reduces input, waste, and energy costs—all while improving product quality.

Once up and running, resin sand recycling delivers savings across the board:

- Reclaim rate of 90–95%: drastically cuts raw sand purchases

- Lower waste volume: disposal costs drop significantly

- Improved sand quality: fewer defects, less rework

- Energy-efficient machines: especially with inverter fans and auto-feeders

- Consistent LOI and grain shape: better castings, fewer rejects

💡 Some foundries also use less binder with reclaimed sand—saving even more.

4. ROI Breakdown: What Do Foundries Save Over Time?

Wondering what it really looks like in your books?

Recycling delivers ROI through consistent annual savings—often recouping full investment in just 1–3 years.

| Cost Category | Traditional Disposal | With Recycling System |

|---|---|---|

| New Sand Purchase | High (Recurring) | 70–90% Reduction |

| Waste Disposal Fees | Medium to High | Low to Minimal |

| Compliance Risk | High | Low |

| Manual Labor Costs | Moderate | Low |

| Downtime Risk | Moderate | Low (Automation) |

| Payback Period | — | 1–3 Years |

💡 Real Example: One of our clients cut $80,000/year in operating costs and broke even in 18 months.

5. When Does Recycling Become More Cost-Effective?

Is recycling always worth it?

It’s most effective when disposal costs are high, sand usage is heavy, or strict environmental rules apply.

Recycling offers the best returns when:

- You process over 10 tons of sand per day

- Local disposal or sand sourcing costs are rising

- You operate in a regulated zone (Europe, U.S., parts of Asia)

- You need consistent mold quality with tight tolerances

- You’re working toward sustainability or ESG goals

Even if you’re a smaller operation now, choosing a modular system lets you scale your savings as you grow.

💡 Don’t wait for costs to rise—get ahead of the curve now.

6. Environmental Impact: Cost Avoidance Through Compliance

Worried about inspections or emission rules?

Recycling helps you meet compliance standards, avoid fines, and support ESG goals—all of which have financial value.

Here’s what proper sand recycling helps you avoid:

- Penalties from dust or emissions violations

- Costly delays from failed audits

- Negative PR that could hurt OEM partnerships

- Scrap costs from inconsistent molds due to low-quality sand

Compliance today isn’t just about fines—it’s about maintaining your reputation, operations, and contracts with top-tier buyers who value sustainability.

💡 You might even qualify for tax breaks or green manufacturing grants.

Final Verdict: Recycling Wins in the Long Run

While the upfront cost of a resin sand recycling system may seem high, the long-term savings, quality improvement, and environmental compliance make it a smarter investment for most foundries. If your operation uses large volumes of resin sand, recycling isn’t just cheaper—it’s essential.

FAQ (SEO Friendly)

Q1: Is resin sand recycling always cheaper than disposal?

In medium-to-high volume operations, yes. Especially when factoring in disposal, labor, and new sand purchases.

Q2: How long does it take to break even on a resin sand recycling system?

Typical payback periods range from 1 to 3 years depending on sand usage and local disposal costs.

Q3: Are there government incentives for switching to recycling?

In many regions, yes—ask your supplier about local subsidies or environmental grants.