If there’s one thing I’ve learned after years working with resin sand mixers, it’s this: the real cost isn’t just in what you pay upfront — it’s in keeping the machine running day after day. A mixer that looks affordable at first can become a nightmare if maintenance is a constant battle.

Inadequate maintenance planning leads to unplanned downtime, poor mixing results, and wasted resin — and these costs add up fast. Before signing the order, there are a few questions I always recommend asking your supplier to protect your investment and your production schedule.

Why Maintenance Should Drive Your Mixer Choice

Too many shops focus on the purchase price and ignore the maintenance reality. Over the years, I’ve seen plenty of mixers sit idle because operators couldn’t clean them properly or spare parts took forever to arrive.

A good mixer should be easy to service, with parts that are accessible and durable. In the long run, it’s these details that keep you productive and profitable.

The Real Maintenance Needs of Resin Sand Mixers

Any mixer needs routine attention, whether it’s brand new or five years old. In my shop, here’s the checklist we run through:

- Daily: Clean the blades and mixing chamber, inspect resin lines for clogs, check nozzles for buildup.

- Weekly: Lubricate moving parts, check liner wear, replace seals or gaskets showing early damage.

- Monthly: Inspect dosing systems, recalibrate flow sensors, and check motor alignment and vibration.

Parts you’ll replace most often:

- Blades: They take the brunt of the wear and directly affect your mixing quality.

- Liner Plates: Protect the chamber but slowly degrade with abrasive contact.

- Dosing Nozzles: If these clog or wear unevenly, your resin mix becomes unreliable.

I’ve seen shops skip daily checks, only to find hardened resin the next morning — turning a 10-minute task into a multi-hour teardown.

Top Maintenance Questions to Ask Your Supplier

1. How easy is it to access and clean critical parts?

- Can you open the chamber without special tools?

- Are blades coated to reduce sticking?

A mixer that takes an hour to open will cost you much more in labor over time. I always look for tool-free access and smart design to reduce resin buildup.

2. What’s the typical lifespan and cost of key wear parts?

- How long do the blades last?

- Are spare parts stocked locally?

If the manufacturer can’t tell you average replacement intervals, that’s a red flag. You don’t want to be waiting weeks for a simple blade or liner replacement.

3. Does it have built-in error detection or self-diagnostics?

- Will it alert me to clogs or uneven mixing?

- Does it track downtime or maintenance intervals?

Modern mixers can warn you before things go wrong. I’ve avoided major failures thanks to early sensor alerts.

4. How much downtime should I expect for cleaning and maintenance?

- Can you do partial cleanings without full disassembly?

- Are there quick-swap parts?

A few hours saved per week can add up to huge gains over the year. Some mixers I’ve used allow partial cleaning between shifts — a major advantage.

5. What level of support and training is offered?

- On-site training?

- Remote troubleshooting or videos?

- Spare part kits included?

A solid support system means faster fixes and fewer headaches. I’ve worked with suppliers who send technicians on-site within 48 hours, and that responsiveness can make all the difference when production is at stake.

Resin-Specific Maintenance Challenges

Different resins affect maintenance differently. For example:

- Furan resins tend to cause more buildup and clogging.

- PUCB systems require precise temperature control, which affects cleaning frequency.

- Some resins create aggressive fumes that attack seals or adjacent equipment if ventilation isn’t managed well.

I always advise planning for extra cleaning time if you use furan or similar resins — prevention saves expensive repairs.

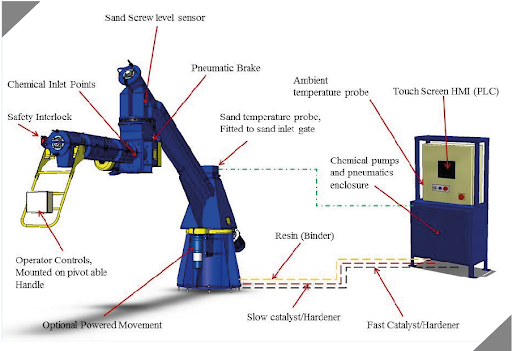

Automation Features That Help

I’ve seen great improvements in the last decade thanks to automation. Look for features like:

- Automatic flushing of resin lines.

- Blade anti-stick coatings.

- Live monitoring for flow consistency and clog detection.

- Fully enclosed, dust-free designs.

These small engineering upgrades can make a huge difference in daily operations, especially if you run multiple shifts.

The Hidden Maintenance Costs You Might Overlook

In my experience, these are the costs that surprise new buyers the most:

- Resin waste from poor flushing: Adds up quickly in material costs.

- Extended downtime from hard-to-source parts: Stops production entirely.

- High-priced, proprietary spare parts: Some mixers lock you into their supply chain at inflated prices.

- Secondary damage to nearby equipment from fumes or dust: Unexpected and often overlooked.

Real-World Example: High vs Low Maintenance Mixer

One foundry I worked with bought a cheaper mixer to save budget upfront. But constant daily cleaning and frequent part failures led to constant downtime. They lost more money in two years than if they’d bought a higher-end model from the start.

Another customer invested in a self-cleaning mixer with diagnostic features. Their downtime dropped by 30%, and they had more predictable production schedules — fewer headaches and more profit.

Quick Maintenance Questions Checklist

| ✅ Maintenance Question | Why It Matters |

|---|---|

| How easy is daily cleaning? | Impacts operator time and shifts. |

| Are parts readily available? | Prevents long, costly downtimes. |

| Expected lifespan of wear parts? | Allows budget and stock planning. |

| On-site service available? | Reduces troubleshooting delays. |

| Can components be accessed quickly? | Faster maintenance, safer for staff. |

Conclusion: Maintenance is Part of Your Profit

A resin sand mixer is not just a machine — it’s a partner in your production line. If it’s unreliable or hard to maintain, it eats into your profits every single day.

Always focus on maintenance as much as performance when choosing a mixer. Ask the tough questions now to avoid bigger problems later.

Call to Action

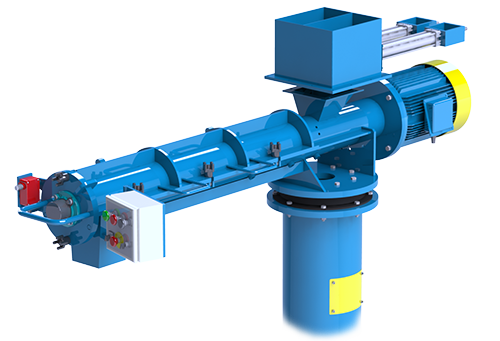

At Hitech-China, our mixers are designed with maintenance at the forefront: quick access, durable components, and strong local support.

👉 Talk to us to learn how we can help you minimize downtime and maximize productivity.