Integrated Resin Sand Shakeout Machine — Say Goodbye to Dust, Delay, and Manual Work

One machine handles shakeout, sand separation, and dust — faster, cleaner, and easier.

Shakeout delays, dust, and labor costs add up fast. As a direct manufacturer, we deliver an all-in-one solution that keeps your workflow clean, fast, and efficient.

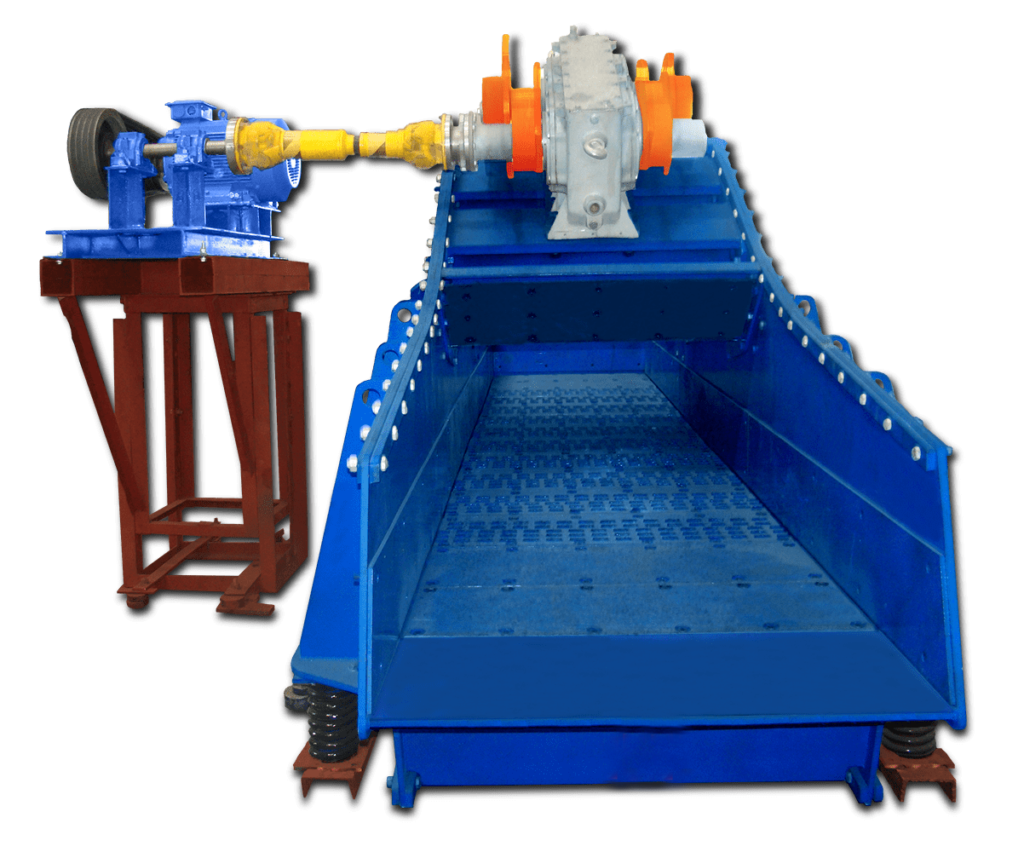

About Integrated Resin Sand Shakeout Machine Overview

Slow shakeout, heavy manual cleanup, and excessive dust are constant pain points in foundry operations. These issues not only lower efficiency but also increase labor intensity and compromise workplace safety.

As a direct manufacturer, we build the Integrated Resin Sand Shakeout Machine to solve these challenges at the root. It combines vibration shakeout, sand-core separation, and dust control into one compact system — designed for real-world production environments.

By reducing manual work and improving sand handling efficiency, this machine helps you streamline the shakeout process, reduce downtime, and maintain a cleaner, more organized workshop.

We offer a range of significant benefits:

Manual shakeout is slow, physically demanding, and inconsistent. Our integrated system automates the process, reducing labor intensity and improving work safety.

Dust from traditional shakeout contaminates the air and workshop environment. With enclosed dust collection, our machine keeps your workspace cleaner and more compliant with safety standards.

Slow sand-core separation causes delays in cleaning and finishing. Our powerful vibration mechanism speeds up shakeout, helping you move castings faster to the next stage.

Instead of multiple separate systems, this all-in-one machine saves floor space while delivering full-process efficiency — ideal for both upgrades and new lines.

From structural strength to wear-resistant components, every part is engineered for continuous, heavy-duty operation — tested and assembled in our own factory to ensure long-term reliability.

Get a Quote

Bibendum ornare consectetur maecenas scelerisque vehicula gravida tempus lorem odio

Need more help?

Venenatis mauris sapien luctus nascetur dui ornare metus ligula sit dolor adipiscing ad lobortis dapibus litora senectus duis

888-4000-234

888-4000-234

Comprehensive Support and ServicesAlways Providing the Help You Need

Production delays, unclear instructions, and slow after-sales response don’t just waste time — they cost you output, manpower, and trust in your equipment.

We understand these risks because we build for real foundries. That’s why our support is designed to keep you running: faster commissioning, intuitive operation guidance, and quick technical response when every hour matters.

You don’t just receive a machine — you gain the stability, clarity, and assurance to keep your workflow on track from day one.

Technical Specification of Integrated Resin Sand Shakeout Machine - Technical Specifications

Reliable Performance Tailored to Real-World Foundry Conditions

Inconsistent shakeout force, overload risks, and poor adaptability to different casting sizes often result in casting damage, excessive wear, and unstable production rhythms. That’s why choosing the right model is critical.

Our integrated resin sand shakeout machines are engineered to handle a wide range of payloads — from 3 to 30 tons — with vibration systems precisely configured for casting size, sand load, and grid layout. Whether you’re working with small molds or heavy-duty cores, there’s a model to match your production scale and floor space.

Key Technical Parameters

| Model | Payload (T) | Machine Weight (KG) | Mesa Dimension (mm) | Overall Dimension (mm) | Motor Power (KW) |

|---|---|---|---|---|---|

| L123 | 3 | 3800 | 2000×1800 | 2300×1900×1000 | 3.7×2 |

| L125 | 5 | 5500 | 2500×2000 | 3000×2000×1120 | 5.5×2 |

| L1210 | 10 | 11000 | 3000×2500 | 3560×2200×1280 | 9.5×2 |

| L1215 | 15 | 13500 | 3000×3000 | 4060×2800×1280 | 12.0×2 |

| L1220 | 20 | 23000 | 4000×3000 | 4500×3000×1330 | 8.5×4 |

| L1225 | 25 | 25800 | 4000×3000 | 5000×3200×1360 | 9.5×4 |

| L1230 | 30 | 30000 | 4000×3000 | 5000×3200×1360 | 1.20×4 |

Why Choose Us

Unmatched Quality and Innovation

Discover the Difference with Our Advanced Shot Blasting Solutions”

Leverage cutting-edge shot blasting technology for superior results

Description: "Tailored solutions designed to meet specific industrial needs

Durable machines built to last, even in the toughest environments

Reduce operating costs with energy-efficient designs

Benefit from our expert support team available around the clock

Trust in our global expertise and extensive installation base

Description: "Adhere to environmental standards with eco-friendly technologies."

Enjoy low maintenance costs due to high-quality components

Our machines meet the highest standards of safety and compliance

What you need

Comprehensive Shot Blasting Systems

Hitech machines are designed and engineered according to our customers’ specific requirements and specifications. Each component is assembled with meticulous attention to quality by our in-house fabrication team, ensuring every unit meets the highest standards

This machine efficiently processes inner and outer walls of steel pipes, casings, cylinders, and other tubular metal items

Designed specifically for cleaning anchor chains and heavy-duty chains, this shot blasting machine effectively removes rust, enhances metal surface quality, and extends service life

Designed specifically for the surface treatment of wire rods and long bars, this shot blasting system efficiently removes oxide layers and rust, enhancing surface quality and paint preparation

Ideal for large-scale field operations, this portable shot blasting machine is specifically designed for cleaning external walls of steel pipes, quickly removing rust and old paint, effectively enhancing paint adhesion.

Designed for surface treatment of small and medium-sized parts, this machine offers uniform shot blasting through a rotary table, suitable for metal parts of various complex shapes

This machine offers efficient cleaning and preparation for roads and large floor areas, suitable for removing road markings, stains, and enhancing roughness to improve traction

Professional Team, Focused on Details

Precision Installation & Commissioning — Safeguarding Your Production Efficiency

With over 25 years of experience in installing and commissioning shot blasting machines, our expert team not only ensures precise installations but also optimizes configurations based on your specific needs. From initial setup to full-scale commissioning, we provide guidance throughout, ensuring every step meets the highest standards to enhance the efficiency and stability of your production line. Choosing Hitech means choosing a worry-free startup and operation.

Client say hitech

Customer Testimonials — Our Success Stories

Discover genuine testimonials from customers across industries. They share their experiences with Hitech, showcasing our commitment and achievements in delivering high-quality products and top-tier services

Let’s Discuss Your Shot Blast Needs

We are ready to hear about your needs. Partner with Hitech to create your success story. Contact us to begin the conversation