Struggling with rising raw material costs and stricter environmental rules?

Before buying a resin sand molding recycling system, you must ask the right questions. This guide reveals the 7 most important ones to ensure a smart, future-proof investment.

Choosing wrong costs more than money—it risks downtime, compliance issues, and poor casting quality. Let’s break it all down together.

1. What’s Your Current and Future Production Capacity?

Facing inconsistent output and unsure if the new line will keep up?

Start by calculating how much reclaimed sand you need now—and what you’ll need in the next 3–5 years. Choose a system that matches both.

A mismatch in capacity is one of the most common (and expensive) mistakes I’ve seen clients make. When planning for resin sand recycling, always begin with throughput. Ask yourself:

- How many tons/hour do we reclaim now?

- Will we shift to higher casting volumes soon?

- What sand type are we using—furan, phenolic, or sodium silicate?

Each resin type affects how the equipment performs. Furan-based systems, for example, often require more robust scrubbing functions due to tougher residue. If your foundry is growing, don’t box yourself in with a fixed system. Modular designs allow you to scale production without reinvesting in a whole new line.

Here's a simple comparison table:

| Factor | Fixed System | Modular System |

|---|---|---|

| Scalability | ❌ | ✅ |

| Initial Cost | Lower | Higher |

| Upgrade Flexibility | Limited | High |

| Maintenance Access | Moderate | Easy |

| Ideal For | Small Shops | Growth Foundries |

💡 Pro Tip: Choose modular systems for easier upgrades and future-proofing.

2. Will It Deliver High-Quality Reclaimed Sand?

Not sure if the recycled sand will be good enough for critical castings?

Focus on systems that consistently produce reclaimed sand with optimal grain size, low LOI, and minimal resin residue.

When customers approach me, they often worry: “Will the recycled sand ruin our molds?” That fear is valid. Sand quality affects everything—mold strength, permeability, surface finish, and casting defects.

Here’s how I recommend evaluating quality:

- Grain Size Distribution: Must remain consistent to avoid casting defects.

- Loss on Ignition (LOI): Should be <0.3% for most applications.

- Fines and Resin Residue: Systems should filter out impurities effectively.

Ask for lab test reports or better yet—a real reclaimed sand sample from the supplier’s existing customers. Also, check whether the system uses a scrubbing, magnetic separation, or even thermal reclamation stage. Each adds a layer of cleaning precision.

💡 A test run can save you from a long-term headache.

3. What’s Included in the System Configuration?

Tired of hidden costs and missing components?

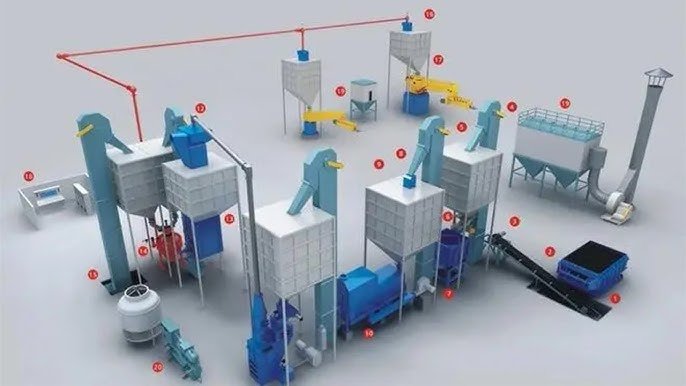

Ensure the recycling system comes fully equipped: crushers, sieves, conveyors, dust collectors, and control automation.

Too often, I’ve seen foundries buy what looks like a “complete system” only to realize they need to separately source a dust collector or control panel. That’s a planning nightmare.

Here’s a checklist you can use:

| Component | Included (✔/✘) |

|---|---|

| Sand Crusher | ✔ |

| Vibratory Sieve | ✔ |

| Magnetic Separator | ✔ |

| Dust Collector | ✔ |

| PLC Control Panel | ✔ |

| Auto Feeding & Discharge | ✔ |

| Cooling Unit (Optional) | ✔ |

Don’t forget about automation. A PLC system doesn’t just reduce labor—it prevents operator errors and gives you real-time control and diagnostics.

💡 Pro Tip: Higher automation = lower labor costs and fewer errors.

4. Does It Meet Environmental & Energy Standards?

Worried about fines or energy inefficiency?

Look for systems that comply with local dust emissions laws and minimize power consumption with energy-efficient motors and blowers.

Every country has its own emissions and energy codes—and they’re getting stricter. You don’t want to buy a system only to find out it fails inspection. I’ve seen clients in Europe and Southeast Asia both face shutdowns because of non-compliant dust collection.

Energy-saving tips:

- Choose frequency-controlled motors for fans and conveyors.

- Look for third-party certifications or ISO reports for environmental compliance.

- Ask for filtration efficiency specs (e.g., ≤20mg/m³ dust emission).

Not only do these reduce your environmental footprint—they cut your monthly power bill too.

💡 Ask your supplier for recent test reports or third-party audits.

5. Is Maintenance Easy and Are Spare Parts Available?

Worried about downtime due to maintenance issues?

Ensure critical parts are wear-resistant, easily replaceable, and backed by clear maintenance support.

In my experience, maintenance makes or breaks a shot blasting or sand reclaiming system. The best hardware means little if a worn liner shuts you down for a week.

Here’s what I always recommend checking:

- Are liners made of high-hardness alloy?

- How often must I replace bearings, belts, or screens?

- Is a spare parts kit included?

- Will they offer a maintenance manual or training video?

You’ll want local availability or express shipping options for spares. Also, confirm if they offer on-site training or virtual commissioning to guide your maintenance team.

💡 Ask: For a spare parts kit and maintenance estimate upfront.

6. How Reliable Is the Supplier’s Support and Service?

Burned by poor service in the past?

Choose suppliers with proven after-sales support, fast response times, and real-world success stories from foundries like yours.

A good machine is only half the battle. When something goes wrong, you need fast, clear, and technically sound support. I’ve helped clients recover from supplier no-shows and miscommunication disasters—don’t be that story.

Ask these key questions:

- Can you show photos or videos from installed systems?

- Do you provide installation, commissioning, and training?

- What’s your response time for international service?

Here’s what a great support offer looks like:

| Service | Availability |

|---|---|

| Installation Supervision | ✅ |

| Remote Troubleshooting | ✅ |

| Annual Maintenance Plans | ✅ |

| 24h Spare Parts Dispatch | ✅ |

| Customer References | ✅ |

💡 Always ask for reference customers or a case study.

7. What’s the ROI and Total Cost of Ownership?

Trying to justify the investment to your finance team?

Calculate not just the purchase price—but total cost over time including savings on raw sand and disposal.

ROI is the ultimate decider. I help clients model ROI across a 3–5 year span, factoring in:

- Annual reclaimed sand vs new sand cost

- Waste disposal fees saved

- Labor saved via automation

- Maintenance and electricity cost

Here’s a simplified ROI template you can request from your supplier:

| Cost Item | Yearly Cost (Old) | Yearly Cost (New) | Savings |

|---|---|---|---|

| New Sand Purchase | $120,000 | $30,000 | $90,000 |

| Disposal Cost | $25,000 | $5,000 | $20,000 |

| Labor & Downtime | $40,000 | $20,000 | $20,000 |

| Maintenance | $15,000 | $18,000 | -$3,000 |

| Total Annual Savings | $127,000 |

💡 A smart system pays for itself—often in under 2 years.

Final Takeaway: Ask the Right Questions to Get the Right System

Don’t get distracted by price tags alone. Focus on quality, capacity, service, and ROI. With the right supplier, a resin sand recycling line is a game-changing investment.

FAQ (for Featured Snippet Optimization)

Q1: What is the most important factor when buying a resin sand recycling system?

A system that matches your capacity needs and ensures high-quality reclaimed sand is most important.

Q2: How long does it take to see ROI on a resin sand recycling line?

ROI can often be realized in 1–3 years depending on your sand usage and waste disposal costs.

Q3: Do I need a fully automated system?

Automation reduces manual labor and error rates—ideal for mid to large foundries aiming for efficiency.