Foundry Machines

Designed for the Pressures You Face Daily

When efficiency drops, defects rise, and labor costs climb — our machines bring your production back under control.

Our Product

Foundry Machines Built for Stable Output — Not Just Operation

We don’t just supply foundry machines — we build practical systems to help you reduce scrap, cut downtime, and improve casting consistency.

We build machines that last — using industrial-grade parts, strict quality control, and real-world testing to ensure stable performance, shift after shift.

Our designs evolve with your challenges — integrating vibration control, precision dosing, and smart automation to improve casting results and reduce manual errors.

Every machine we deliver is built around your process. From layout planning to operator habits, we adapt to your real-world needs — not the other way around.

Efficient sand use, energy-saving drives, and reduced consumables — our machines help cut operational costs while supporting long-term environmental goals.

What we offer

Foundry Machine

Defects, downtime, and rising labor cost — we design machines that help you take control, not just keep up.

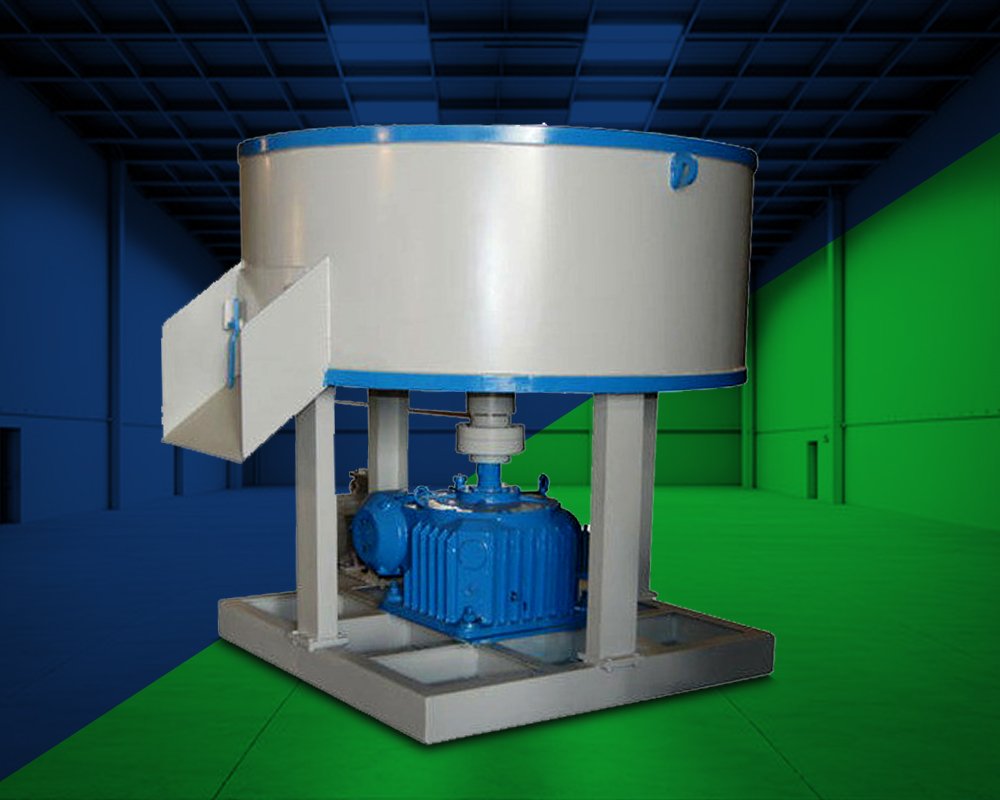

Ensures consistent mixing of silica sand, clay, and water. Enhances mold strength, reduces casting defects, and maintains stable green sand performance across manual or automated molding lines.

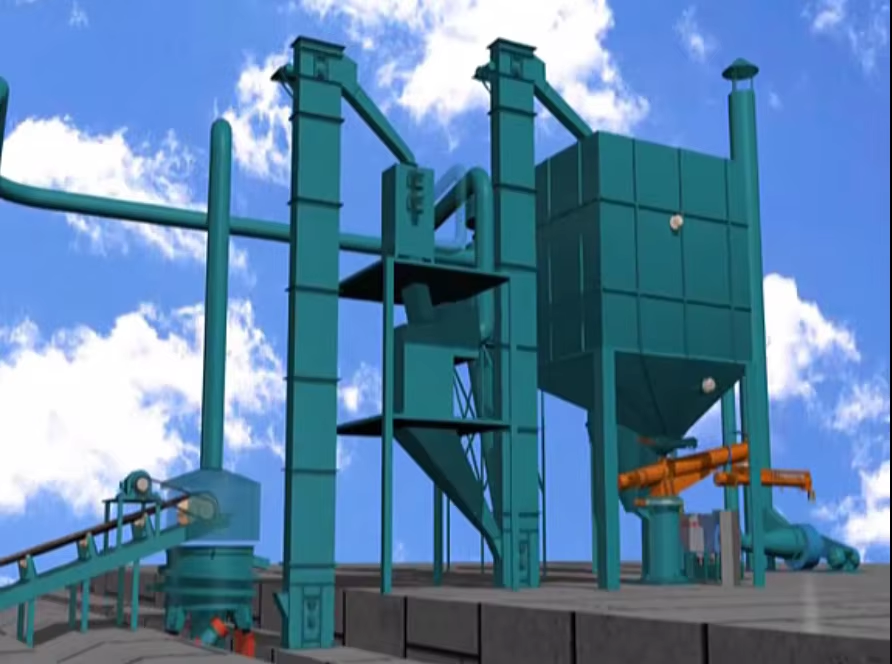

Integrated system for sand molding and reclamation — reduces resin waste, improves sand reuse rate, and ensures clean, efficient casting cycles.

Compact design for uniform mixing of resin, hardener, and sand — ideal for core making and small-batch molding with stable output and easy maintenance.

Combines shakeout, sand separation, and dust control. Increases efficiency, reduces labor, and delivers cleaner castings for resin sand lines with compact design and reliable performance.

Combines jolting and squeezing for firm, uniform mold compaction. Reduces defects, improves casting accuracy, and supports high-efficiency production for small to medium green sand molds.

Fully automated molding without flasks. Ideal for high-speed production of small to medium castings. Reduces labor, improves consistency, and shortens cycle times with stable, space-saving design.

Client say hitech

Customer Testimonials — Our Success Stories

Discover genuine testimonials from customers across industries. They share their experiences with Hitech, showcasing our commitment and achievements in delivering high-quality products and top-tier services

Answering all Your Need with Our Company.

Just send us your casting type, mold size, and output requirements. Our engineers will recommend a suitable model or a full solution layout based on your actual process.

We are a direct manufacturer with our own factory, engineers, and production workshop. All machines are designed, assembled, and tested in-house before delivery.

We provide detailed manuals, operation videos, and remote support. For full lines or complex systems, we can send engineers for on-site or video commissioning.

Hitech machines are designed for energy efficiency and ease of maintenance, significantly cutting down your long-term operating costs.

Let’s Discuss Your Foundry Needs

We are ready to hear about your needs. Partner with Hitech to create your success story. Contact us to begin the conversation