Green sand mixer performance can make or break a foundry’s casting quality—yet too often, small issues lead to major disruptions.

Green sand mixers often face issues like inconsistent moisture, wear, and poor mixing that can hurt casting quality. Real-time monitoring, proper maintenance, and correct additive ratios are key to solving these.

If your castings are showing defects, your green sand mixer might be the hidden culprit. Let’s break down these issues and explore practical, proven fixes.

What Is a Green Sand Mixer and Why It Matters?

Foundry output can suffer when green sand isn't mixed properly—resulting in casting defects and increased scrap rates.

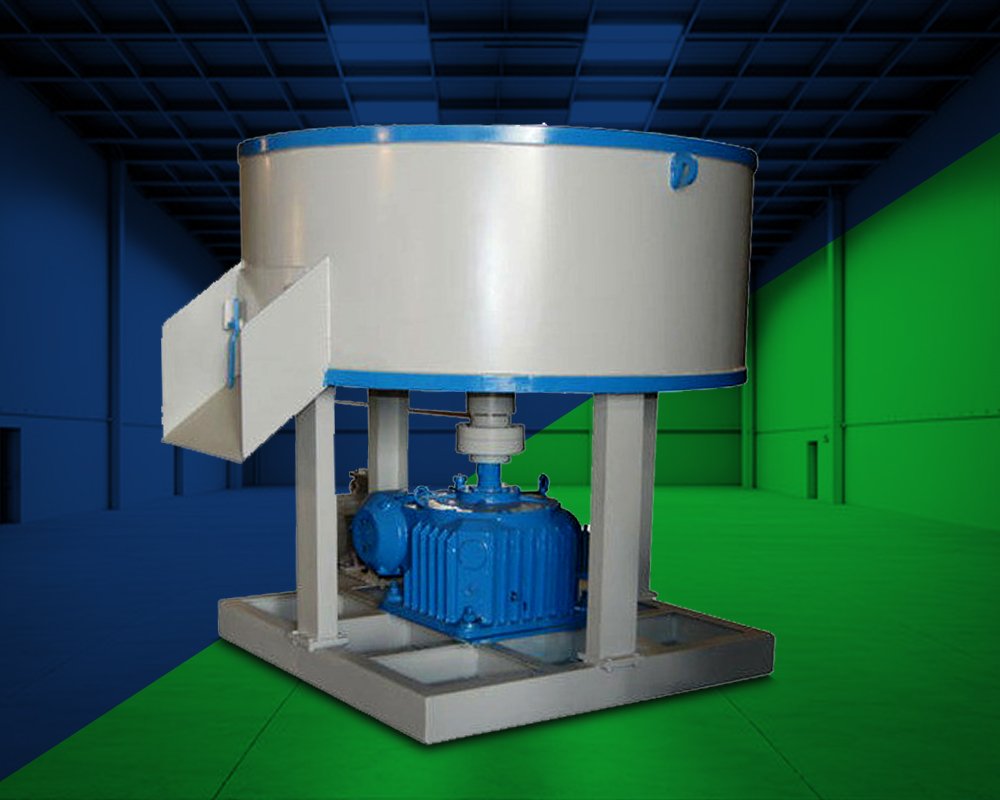

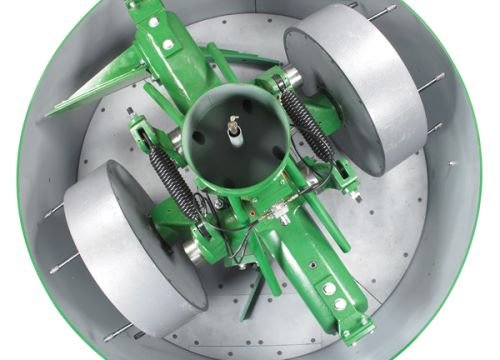

A green sand mixer blends silica sand, clay (usually bentonite), water, and additives to create moldable sand used in metal casting. Consistent, uniform mixing is essential to produce strong and defect-free molds.

In my early days in the industry, I learned quickly that even the most advanced casting lines crumble without a stable molding base. Green sand may seem simple—after all, it’s just sand, water, and clay—but it’s the backbone of metal casting. The mixer’s role is to make sure every grain of sand gets just the right amount of moisture and binder.

There are different types of mixers—batch mixers like mullers or continuous mixers like screw-type. Choosing the right one depends on your foundry’s scale and production needs. However, regardless of type, poor operation or maintenance leads to common, recurring issues.

Most Common Green Sand Mixer Problems?

Even a small imbalance in your sand mix can ripple out across your entire casting line.

The most common issues include inconsistent moisture, poor mixing, equipment wear, sand leakage, and abnormal noise or overheating. Each can lead to reduced mold quality and costly downtime.

Let me break these down with some real-world context:

| Problem | Impact on Casting | Root Cause |

|---|---|---|

| Inconsistent Moisture | Gas porosity, poor finish | Water distribution failure |

| Uneven Mixing | Weak molds, dimensional inaccuracy | Insufficient mixing time or power |

| Excessive Wear | Downtime, frequent repairs | Abrasive sand, poor maintenance |

| Sand Leakage | Material waste, contamination | Damaged seals or worn conveyors |

| Overheating & Noise | Motor burnout, operator safety risk | Bearing failure, overloading |

These problems often show up subtly—until they don't. I’ve seen plants throw away thousands in scrap castings simply because a mixer’s internal paddles were unevenly worn.

Diagnosing a Green Sand Mixer Effectively?

“Shot in the dark” troubleshooting wastes time and money.

Effective diagnosis includes monitoring moisture, temperature, and mixing time in real-time, along with regular checks of paddles, seals, and bearings.

To help with consistent diagnosis, I recommend creating a daily checklist that includes:

| Parameter | Recommended Frequency | Tools to Use |

|---|---|---|

| Sand Moisture Content | Every Shift | Infrared Moisture Sensors |

| Mixing Time | Daily Calibration | Control System Logs |

| Mixer Blade Wear | Weekly | Visual Inspection |

| Sand Temperature | Daily | Thermocouple Sensors |

| Water Flow Rate | Real-Time | Flowmeters |

We once installed real-time moisture sensors in a customer’s facility. Within a week, their defect rate dropped by 30%. Why? Because they could now see when their mixer was drifting out of spec.

You don’t need a million-dollar budget to improve diagnosis. Just build a system of consistent measurements and act on small deviations before they grow.

Proven Solutions for Green Sand Mixer Issues?

Most problems are preventable—with the right tools and processes.

To solve green sand mixer issues, apply moisture sensors, upgrade paddles, introduce cooling, and automate additive dosing. Each measure stabilizes the sand mix quality.

Let’s address common issues with proven fixes:

| Issue | Solution |

|---|---|

| Inconsistent Moisture | Install real-time moisture control with feedback loop |

| High Sand Temperature | Use fluid bed sand coolers |

| Uneven Mixing | Replace worn paddles, verify RPM & timing |

| Additive Ratio Error | Apply automatic dosing system |

| Wear and Tear | Upgrade to wear-resistant materials (e.g., Ni-Hard) |

| Sand Leakage | Reseal joints, replace conveyor skirts |

In one facility, switching from manual bentonite dosing to an automated screw feeder system reduced variation in mold strength dramatically. That small investment returned 3x in saved scrap and reduced downtime.

For mixers operating in hot climates, I highly recommend pre-mixing sand cooling. It makes a bigger difference than many expect.

Maintenance Best Practices for Your Green Sand Mixer?

Without maintenance, even the best mixer becomes a liability.

Follow daily, weekly, and monthly maintenance schedules, focusing on seals, paddles, bearings, and controls. Preventive care reduces costly emergency repairs.

Here’s a sample preventive maintenance schedule we provide to clients:

| Task | Frequency |

|---|---|

| Check blade wear & tension | Weekly |

| Inspect motor temperature | Daily |

| Clean sensors & seals | Daily |

| Grease bearings | Weekly |

| Replace paddles | Every 6 months |

| Calibrate sensors | Monthly |

Preventive maintenance pays for itself. I worked with a facility that moved from reactive repairs to scheduled inspections, and their downtime dropped by 40%. Simple fixes—like tightening a loose belt—can prevent massive failures.

How to Optimize Green Sand Mixer Performance?

Sometimes fixing problems isn’t enough—you need better performance.

Mixer performance can be optimized through automation, operator training, and higher-quality sand. These changes increase consistency and reduce human error.

Three strategies work wonders:

- Automation: Equip your mixer with moisture probes, sand temperature sensors, and PLCs. Automation ensures uniform output regardless of shift or operator.

- Operator Training: Skilled operators detect abnormalities early. We offer half-day training sessions that boost mixer output consistency by over 20%.

- Material Quality: Low-grade return sand hurts performance. Consider reclamation or blending with higher quality sand to stabilize results.

Case in point: a partner in India switched to semi-automated controls and reduced their casting rework rate from 12% to 4%. That’s a real-world return on investment.

When to Repair or Replace a Green Sand Mixer?

At some point, repair costs outweigh the benefits.

Replace your green sand mixer when wear is excessive, downtime increases, or repairs exceed 50% of replacement cost. New mixers offer better efficiency and reliability.

Here’s a decision matrix we share with clients:

| Indicator | Recommendation |

|---|---|

| Repair Cost > 50% New Cost | Replace |

| Frequent Emergency Repairs | Replace |

| Blade or Liner Life < 6mo | Replace |

| Productivity Drop > 20% | Replace or Upgrade |

| Controls Obsolete | Replace or Retrofit |

Before replacing, always get a professional audit. I once helped a client upgrade just their control panel and mixing arms—saving $50,000 over a full replacement.

Final Tips for Long-Term Green Sand Mixer Reliability

Summing it all up—green sand mixer need monitoring, maintenance, and the right settings. Keep moisture stable, check wear parts often, and never skip training.

✅ Quick Checklist for Stable Operation

- Moisture sensor calibrated

- Mixing time verified

- Paddle wear below threshold

- Bearings lubricated weekly

- Additive dosage automated

- Sand temperature within target

- Sand leakage eliminated

Conclusion

Green sand mixer issues can quietly derail your foundry. By identifying problems early and applying targeted solutions—from moisture control to smart upgrades—you secure casting quality and plant efficiency.