Rust, mill scale, pitting—these common surface issues ruin coatings and shorten pipe life. Many projects fail before they even begin due to poor surface prep.

Steel pipe surface preparation is the foundation of coating and welding success. Identifying surface issues early and applying targeted shot blasting solutions helps prevent costly failures.

In this article, I’ll share the most frequent issues I’ve encountered in pipe production lines and the practical solutions we've implemented for clients across oil, gas, and infrastructure projects.

Why Surface Preparation Matters in Pipe Projects

Coating failures, leaks, and welding defects are often blamed on materials or environment. In most cases, though, the real issue is poor surface preparation.

Without proper cleaning, steel pipe surfaces retain rust, scale, or moisture—compromising coating adhesion and reducing corrosion resistance.

In one case, a customer shipping coated pipes to the Middle East found that coatings began to peel just weeks after application. After review, we discovered that blast cleaning was insufficient and inconsistent—especially inside the pipe bore. Once they upgraded to a dual-system shot blaster and controlled humidity during processing, defect rates dropped to under 2%.

Pipe projects, especially in oil, gas, and water supply, need consistent preparation to meet specifications like Sa2.5 or Sa3.0. This is not just about blasting—it’s about controlling each step from storage to priming.

Common Surface Challenges in Steel Pipe Projects

1. Rust and Oxidation

Issue: Rust forms during storage, especially in humid or coastal areas.

Impact: Prevents coatings from bonding properly; accelerates corrosion under the paint layer.

Solution: Use a steel grit-based shot blasting machine for aggressive cleaning. Apply primer within 2 hours to avoid flash rusting.

2. Mill Scale Contamination

Issue: Oxide layers from hot rolling remain on pipe surfaces.

Impact: Coatings delaminate over time, especially under mechanical stress.

Solution: Achieve Sa2.5 or better using high-speed turbine shot blasting. Regularly monitor abrasive condition and blasting angle.

3. Surface Pitting or Scars

Issue: Mishandling with hooks or poor grinding practices before blasting.

Impact: Creates weak points for coating failure or corrosion initiation.

Solution: Inspect pipes for scars before blasting. Use consistent blast profile settings to ensure even cleaning without over-cutting soft areas.

These issues are common in both spiral-welded and seamless pipes. Whether you're dealing with water pipes, oil tubes, or structural pipe, proper diagnosis and adjustment of surface treatment processes is critical.

Surface Preparation Methods Compared

Choosing the wrong preparation method adds cost and delays. We’ve tested all standard methods across hundreds of production lines.

Shot blasting outperforms other surface prep methods in efficiency, consistency, and environmental safety.

| Method | Effectiveness | Speed | Suitability |

|---|---|---|---|

| Manual Cleaning | Low | Very slow | Only for repair or touch-up |

| Chemical Pickling | Medium | Moderate | Suitable only with full waste treatment systems |

| Shot Blasting | High | Fast | Best for steel pipe mass processing |

Shot blasting also allows for in-line media recycling, reducing abrasive consumption and operational costs.

From a cost-efficiency perspective, our clients typically see ROI within 8–12 months after switching from manual or pickling processes to high-throughput shot blasting.

Expert Tips for Better Surface Results

In the field, the details matter. Over the years, I’ve developed a checklist of best practices based on what works consistently.

Applying these proven tips in your process can reduce defects and rework while improving coating durability.

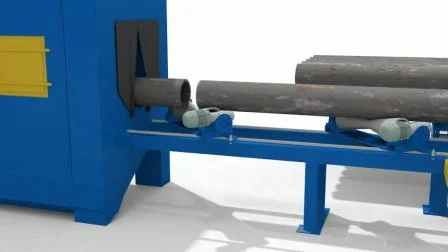

- Use pipe-specific shot blasting machines with internal nozzles and external blast wheels for 360° coverage.

- Keep ambient humidity below 60% during the blasting and pre-coating stages to prevent flash rust.

- Ensure your machine has inline dust collection and media recycling to maintain blasting consistency and environmental compliance.

- Conduct routine inspection of blast wheel wear, nozzle alignment, and media size to keep your surface profile consistent.

- Apply primer within 2–4 hours after blasting, depending on environmental conditions, to lock in the clean surface.

We often customize machines with automatic loading arms and pre-heaters for customers in cold or humid climates to ensure surface prep remains stable year-round.

FAQs

Q: What Sa standard should I aim for in coating pipes?

A: Sa2.5 is the most common standard. For high-performance coatings or harsh environments, use Sa3.0.

Q: How soon should I apply primer after blasting?

A: Within 2–4 hours. Any longer and flash rust or airborne dust can compromise coating adhesion.

Q: Can I use one machine for both inside and outside pipe blasting?

A: Yes, we offer combined systems with rotating internal nozzles and external blast wheels.

Q: What’s better for surface profile—steel shot or grit?

A: Grit gives a deeper, angular profile for thick coatings. Shot provides a smoother finish for thin coats or decorative painting.

Q: How do I prevent uneven blasting?

A: Regularly check blast wheel alignment, media recycling cleanliness, and part feed rate. Consistency in machine settings is key.

Conclusion

Steel pipe surface preparation is not just a step—it’s a critical success factor for coatings, welding, and longevity. By addressing common issues like rust, scale, and pitting with the right shot blasting system and process controls, you can reduce failures, save costs, and deliver higher-quality products.

Need guidance selecting the right preparation system for your pipe line? Let our engineering team help you design a tailored solution.