A few years back, I visited a jobbing foundry outside Jakarta. They had recently upgraded to a new molding machine—but their scrap rate had doubled. The reason? A mismatch between what they bought and what they actually needed.

A green sand molding machine isn’t just another asset—it’s the backbone of your casting operation. If it doesn’t match your workflow, it becomes your biggest bottleneck.

And yet, too many foundries focus on price or catalog specs and forget what really matters on the floor: fit, flexibility, and future-readiness.

What Is a Green Sand Molding Machine (and Why Should You Care)?

Let’s get something straight: “green” doesn’t mean environmentally friendly—it means wet, uncured sand.

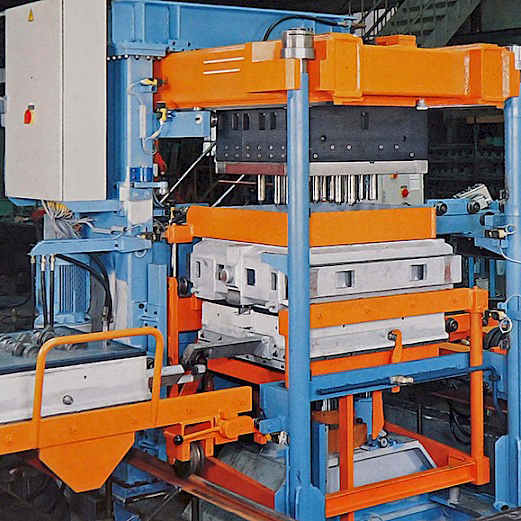

A green sand molding machine compacts a mix of silica sand, clay, and water into reusable molds, enabling fast, cost-effective casting of iron, aluminum, and bronze.

In one project in Bangladesh, we replaced three manual ramming stations with a single vertical squeeze machine. The result? Dimensional variation on flanged housings dropped by 68%, and rework costs fell by half.

| Why Foundries Still Prefer Green Sand | Impact |

|---|---|

| Reusable media (90%+ reclaimable) | Cuts raw material cost |

| Flexible with alloys and shapes | Fewer changeovers |

| Low tooling cost | Ideal for prototyping & small series |

| Fast cycle time | Keeps up with batch production |

Takeaway: If you're casting medium-weight parts under 500 kg and want control without high investment, green sand remains your best bet.

Manual vs Semi-Automatic vs Fully Automatic—What Really Works?

I still remember Mr. Long, a foundry manager in northern Vietnam, proudly telling me his team had “never needed a machine” to make molds. That was true—until he landed a contract requiring 150 castings a day.

Manual hammers couldn’t keep up.

The right level of automation depends on volume, operator skills, and how much downtime you can tolerate.

| Type | Best For | Labor Need | Cycle Time | Mold Quality |

|---|---|---|---|---|

| Manual | Low volumes, unique shapes | High | 5–10 min | Variable |

| Semi-Auto | Batch production (50–200/day) | Moderate | 1–2 min | Good |

| Fully Auto | Mass production (200+/day) | Low | 45–90 sec | Excellent |

We helped one Sri Lankan customer install a twin-station semi-auto unit. They cut mold cycle time by 65%, without changing their layout or retraining their whole team.

Takeaway: Choose automation based on actual workflow needs—not factory brochure dreams.

What Features Actually Matter (And Which Are Just Noise)?

Specs are easy to list. What’s harder is knowing what truly improves your bottom line.

Key features include mold size range, squeezing precision, air/power consumption, and downstream compatibility.

| Feature | Why It Matters |

|---|---|

| Mold size capacity | Impacts part flexibility and pattern investment |

| Squeeze force control | Affects dimensional repeatability |

| Air/power usage | Drives long-term operating cost |

| Accessibility | Impacts maintenance downtime |

| Integration ready | Allows add-ons: core setters, conveyors, vision systems |

I’ve seen too many buyers regret ignoring these. One European firm forgot to factor in sand return system clearance. They paid double later to retrofit ducting around support pillars.

Takeaway: Don’t just ask what it does—ask how it fits your process and floorplan.

Choose for Today—and Tomorrow

We once helped a foundry in Turkey upgrade from a manual line to a semi-auto system. Within a year, they doubled volume. But they didn’t plan for further growth—and had to scrap half their tooling during their next expansion.

Choose a machine that fits your current volume—but doesn’t cap your future.

| Planning Point | What to Consider |

|---|---|

| Volume forecast | Will output grow by 50–100% in 2 years? |

| Space constraints | Can your building support automation modules? |

| Training capacity | Do you have the technicians to support automation? |

| Energy infrastructure | Check compressed air and breaker availability |

Takeaway: A machine that gives you 18–24 months of stable ROI and allows modular upgrades is always smarter than one that maxes out on day one.

The Small-to-Mid Foundry Sweet Spot

If you're running 50 to 200 molds/day, here’s what I tell most clients: go semi-auto with quick-change tooling, and leave space for automation extensions.

Features that work:

- Rotating tables with dual stations

- Simple HMI panel (not over-computerized)

- Modular air control unit

- Replaceable flask support frame

A client in Thailand recently cut per-mold time from 4 minutes to 90 seconds, just by switching from manual to semi-auto and reorganizing sand supply.

Takeaway: Don’t jump to full auto unless your demand justifies it—and your team can handle it.

For High-Output Operations: Full Auto Is the Standard

If you're making more than 10,000 parts per month, anything less than full auto will cost you in downtime and rework.

Modern automatic lines come with programmable logic, smart flask handling, and data feedback loops.

We installed a line in Egypt with inline core setting and mold tracking. Their casting failure rate dropped from 7.5% to under 1.2%—and they could now predict maintenance 48 hours in advance using sensor data.

Takeaway: For OEM supply, you need uptime, traceability, and consistency—manual just won’t cut it.

Common Mistakes That Kill Performance

The biggest errors I see?

- Buying based on price instead of TCO

- Ignoring layout and sand flow integration

- Forgetting training and spare parts support

- Choosing machines that require more infrastructure than your plant has

One Mexican client saved $15,000 upfront but spent $27,000 more over the next year correcting system mismatches and retraining staff.

Takeaway: You don’t buy a machine—you buy into a workflow. Make sure it fits.

Get the Best Out of Your Machine—Whatever the Type

You’d be surprised how often performance problems come down to moisture control or worn patterns.

Best practices:

- Moisture content: Keep at 3.0–3.5%

- Replace patterns every 2,500 molds

- Monitor squeeze pressure with load sensors

- Vent patterns properly to avoid blowholes

- Record mold defects and trace back by time/cycle

Takeaway: Your machine’s spec sheet means nothing without daily discipline.

FAQ: Straight Answers to Common Questions

Can I use green sand for aluminum?

Yes—use finer mesh and precise moisture control.

Can I reclaim all sand?

About 85–90% can be reused if you control fines and clay loss.

Service life of the machine?

10–15 years with good maintenance.

How to upgrade without downtime?

Plan in stages—semi-auto modules can be integrated during off-hours or holidays.

Final Word

Your molding machine defines your casting quality, labor efficiency, and expansion path. Don’t buy based on guesswork—match it to your layout, parts, team, and business goals.

It’s not just a machine. It’s the future shape of your foundry.

Meta Description: Choosing a green sand molding machine? This expert guide breaks down manual vs automatic, key features, and smart selection tips for foundry success.