Back when we were running traditional green sand lines in some of our partner foundries across West Africa, quality issues were a constant battle. Inconsistent molds, high scrap rates, dusty work environments—it all added up. We knew we needed a smarter solution.

Upgrading to a resin sand mixing line transformed not just the casting quality, but the entire production workflow—from automation and consistency to environmental compliance and energy savings.

This case study walks through the full journey of one mid-size foundry we supported through this upgrade. From evaluation to execution, we’ll cover the lessons learned and the results that made the investment worth every penny.

What Is a Resin Sand Mixing Line?

Before diving into the project itself, it's important to understand what a resin sand mixing line actually is.

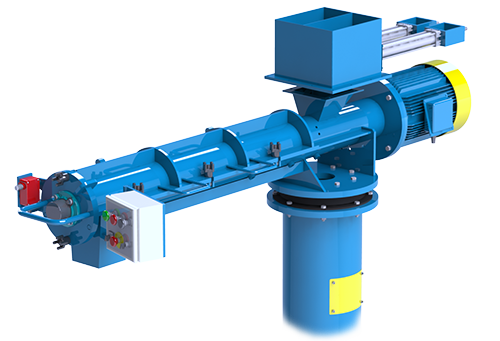

A resin sand mixing line is an automated system that combines silica sand with resin and a curing agent to produce high-strength molds and cores for metal casting.

Compared to green sand systems (which rely on water and clay), resin-bonded sand offers significantly better dimensional accuracy and surface finish. It’s especially useful for large castings or parts with complex geometries.

Key Differences:

| Feature | Green Sand | Resin Sand |

|---|---|---|

| Bonding Agent | Clay + Water | Resin + Catalyst |

| Mold Strength | Moderate | High |

| Surface Finish | Rougher | Smoother |

| Complexity Handling | Limited | Excellent |

| Automation | Low | High |

Resin sand systems also open the door to sand reclamation, tighter process control, and cleaner operations.

Challenges Before the Upgrade

The foundry in question had been using a green sand system for over 12 years. At first, it did the job. But as customer demands increased, the problems began piling up.

Before the upgrade, the plant struggled with inconsistent mold properties, a 12–15% scrap rate, and constant manual labor that made process control almost impossible.

Common issues included:

- Sand batch inconsistencies depending on operator skill

- Frequent downtime for maintenance and mold repairs

- Poor surface finish on final castings, leading to rework

- Dust-heavy work areas that violated local air quality standards

The final straw? A rejected turbine housing order due to dimensional deviation caused by mold collapse—costing the plant a major client and two months of production time.

Why the Foundry Chose a Resin Sand Mixing Line

Management began exploring resin-based systems after benchmarking plants in South Africa and India. The goal was clear: modernize, automate, and compete for higher-spec projects.

The main reasons for upgrading to a resin sand mixing line included better mold accuracy, reduced defects, and the ability to automate a previously labor-heavy process.

They focused on several key factors:

| Driver | Explanation |

|---|---|

| Quality Control | Better mix consistency = fewer casting flaws |

| Mold Complexity | Resin system allows thin walls and intricate shapes |

| Labor Reduction | Automated dosing and mixing cut manual errors |

| Waste Reduction | Reusable sand = less raw material cost |

| Vendor Support | Chose a supplier with local service and training experience |

After comparing three suppliers, they opted for a semi-automated resin mixing line with sand reclamation capability, suited to their existing layout and crane handling system.

Implementation Process and Setup

The upgrade didn’t happen overnight. It took planning, patience, and a few workarounds to align with local infrastructure limits.

Installing the resin sand mixing line took around four months, including training, mechanical installation, and control system commissioning.

Implementation Timeline:

| Phase | Duration | Highlights |

|---|---|---|

| Planning & Design | 4 weeks | Layout optimization, equipment spec |

| Civil Works | 6 weeks | Foundation, ventilation ductwork |

| Installation | 3 weeks | Mixer, silos, sand conveyor setup |

| Commissioning & Training | 2 weeks | Operator certification, test runs |

Challenges included power fluctuations (common in the region), which required adding a stabilizer system. Dust control also had to be upgraded with a new baghouse system to comply with environmental standards.

Performance Improvements After the Upgrade

Once the new system went live, the changes were immediate—and dramatic.

After upgrading, the foundry reported a 60% reduction in scrap, 35% faster mold production times, and a 25% drop in resin usage thanks to better dosing precision.

Measurable Results:

| Metric | Before | After |

|---|---|---|

| Scrap Rate | 12–15% | <5% |

| Mold Cycle Time | 8–10 mins | 3–4 mins |

| Surface Rework Rate | 18% | 4% |

| Resin Waste | 12 kg/day | 7.5 kg/day |

According to the plant manager:

“We used to fix castings after they were poured. Now we fix the mold before the pour—and that’s made all the difference.”

Environmental and Operational Benefits

One of the most appreciated changes was how much cleaner the shop became.

The resin sand system significantly improved air quality, reduced dust, and helped the plant comply with environmental regulations.

Key improvements:

- Closed-loop sand handling system with reduced spillage

- VOC filtration integrated with the mixer exhaust

- Automated cleaning protocols for hopper and mixing chamber

- Lower heat requirements compared to green sand drying

Worker feedback also improved. Reduced manual shoveling and better temperature control made shifts more manageable—especially during hot season production runs.

ROI and Long-Term Impact

From a financial perspective, the project paid for itself much faster than anticipated.

The resin sand mixing line achieved ROI in under 14 months, largely thanks to scrap reduction, resin savings, and faster throughput.

Financial Snapshot:

| Factor | Amount |

|---|---|

| Total Upgrade Cost | ~$180,000 |

| Monthly Savings (avg) | ~$13,500 |

| Break-Even Point | ~13.3 months |

| New Client Orders Secured | 3 large contracts (aerospace + energy) |

The real win? Their newfound ability to quote for jobs they couldn’t even consider before—especially in sectors demanding precision and process documentation.

Lessons Learned and Recommendations

Every upgrade teaches you something. Here’s what stood out in this case:

Planning and operator buy-in are just as important as equipment specs.

Practical Advice:

- Start training early—even before the machine arrives

- Don’t underestimate dust collection needs

- Leave room for future expansion in your layout

- Choose a supplier with post-installation support

Avoid trying to run the old and new systems side by side for too long. It confuses operators and delays full adoption.

Conclusion

Switching to a resin sand mixing line marked a turning point for this foundry—not just in product quality, but in operational confidence and market reach.

If your current sand system is holding you back, it may be time to evaluate what a resin-based line can offer. The benefits—both on the shop floor and in the balance sheet—are hard to ignore.